In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

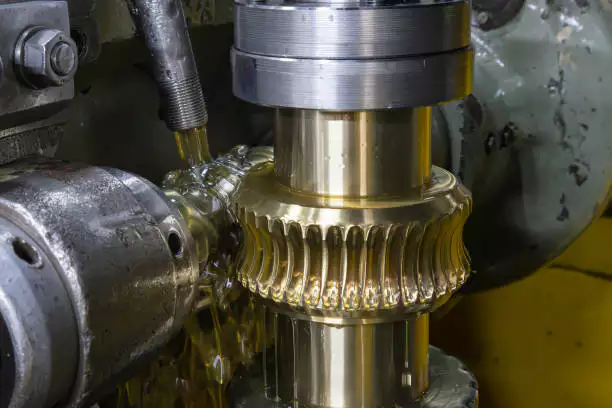

Throated Worm Gear

The Throated Worm Gear is a specialized mechanical component designed to provide efficient power transmission with minimal backlash. Constructed from high-quality materials, it excels in durability and reliability. This gear type includes features of single throated worm gear and threaded rod worm gear, making it ideal for various industrial applications.

Details of Throated Worm Gear

| Parameter | Value |

|---|---|

| Gear Ratio | 10:1 |

| Material | Forged Steel |

| Load Capacity | 500 Nm |

| Output Torque | 50 Nm |

| Efficiency | 90% |

| Operating Temperature | -10 to 100 °C |

Features of Throated Worm Gear

- High Efficiency: The single throated worm gear design minimizes friction, enhancing power transmission and efficiency in applications. This feature is crucial for systems requiring smooth operation and reduced energy loss.

- Versatile Applications: The threaded rod worm gear is versatile, suitable for various industries, including automotive and manufacturing. Its adaptability makes it an excellent choice for diverse mechanical systems.

- Robust Design: Throated worm gear systems are built to withstand high loads and stress, ensuring longevity. Their strength is essential for heavy-duty applications, where reliability is a top priority.

How Throated Worm Gears Work

The throated worm gear is a specialized mechanical component designed to provide efficient power transmission and torque multiplication. It utilizes a single throated worm gear that meshes with a threaded rod worm gear, creating a compact and powerful system. The unique design enhances contact between the worm and gear, reducing friction and wear. This results in smoother operation and increased durability. Throated worm gears are commonly used in various applications where precision and reliability are essential. Their ability to handle high loads while maintaining a compact size makes them an ideal choice for many engineering projects.

Manufacturing Process of Throated Worm Gear

- Design and Engineering: The manufacturing process of a single throated worm gear begins with intricate design and engineering. Using advanced CAD software, engineers create detailed blueprints that incorporate specifications for the threaded rod worm gear. This stage is crucial as it defines the gear's dimensions, thread design, and material selection, ensuring optimal performance and compatibility with other mechanical components. The design must account for load capacities, friction coefficients, and operational environments to deliver a functional and durable throated worm gear. Quality assurance standards are also established in this phase to meet industry requirements.

- Material Selection: Selecting the right materials is essential for producing a reliable throated worm gear. Typically, high-strength steel or bronze is chosen for their durability and wear resistance. The selected materials undergo rigorous testing to ensure they can withstand operational stresses and environmental conditions. During this phase, the threaded rod worm gear's load-bearing capabilities and corrosion resistance are evaluated, guiding the choice of finishes or coatings that may enhance longevity.

- Machining and Fabrication: Once the materials are selected, the machining and fabrication process begins. Using CNC machines, the raw materials are precision-cut into the necessary shapes and sizes as per the design specifications. This includes creating the worm's helical thread and the gear's teeth, which are critical for ensuring smooth interaction between the single throated worm gear and its paired components. The fabrication stage often involves several processes, including milling, turning, and grinding, to achieve the desired tolerances and surface finishes.

- Assembly and Testing: After machining, the components of the throated worm gear are assembled. This stage includes fitting the threaded rod worm gear into the gear housing, ensuring proper alignment and functioning. Comprehensive testing is performed on the assembled unit to evaluate its performance under various loads and conditions. The testing phase helps identify any potential issues before the product is released to the market, ensuring that the throated worm gear meets the highest standards of quality and reliability.

Worm Gear Supplier in Holland

RP Techniek BV is the Dutch sales agent for Ever-power Group and stands as one of the top ten worm gear suppliers in the Netherlands. We specialize in providing high-quality worm gears, including the Throated Worm Gear, which is known for its efficiency and reliability.

- Our products are manufactured to the highest standards, ensuring superior quality and durability.

- We pride ourselves on our extensive experience and expertise in the industry, allowing us to offer customized solutions for various applications.

- Our commitment to customer service means we provide excellent support, ensuring our clients receive the best possible products and assistance.

Additional information

| Edited | Zqq |

|---|

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...