Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

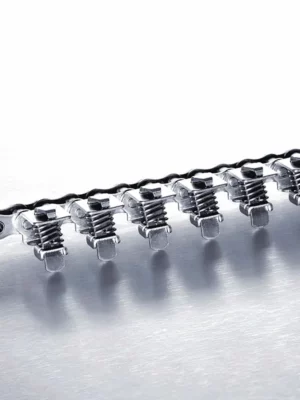

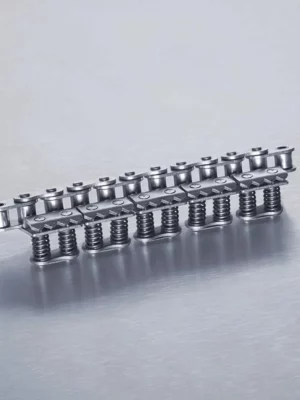

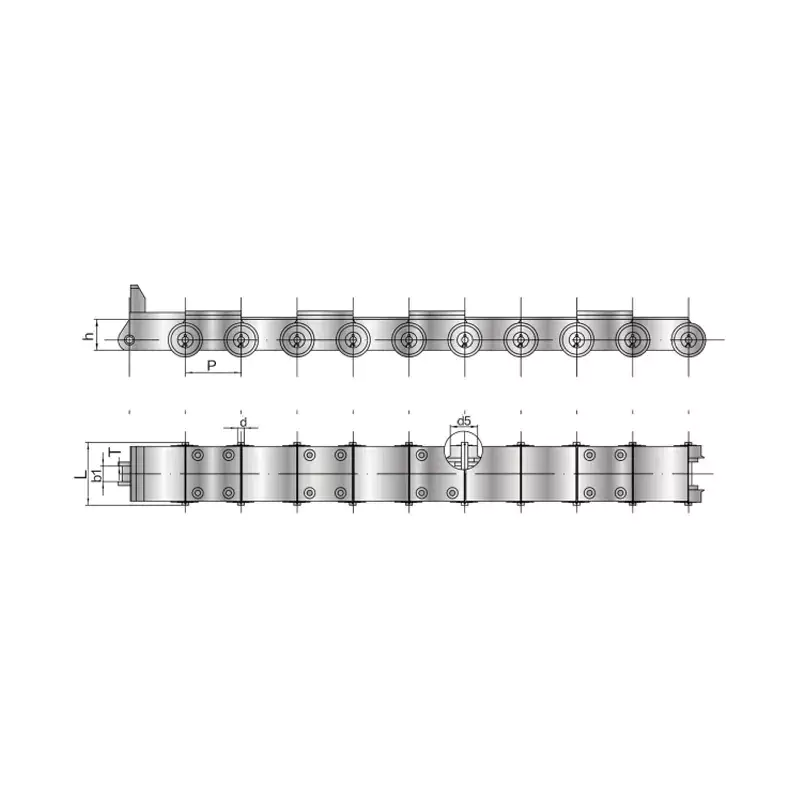

Details of Stainless Steel Metallurgical Electrolysis Cathode Chain for Horizontal Conveyor SSEC81.5

Product Knowledge Introduction: Stainless Steel Metallurgical Electrolysis Cathode Chain for Horizontal Conveyor SSEC81.5

1. Overview

The Stainless Steel Metallurgical Electrolysis Cathode Chain for Horizontal Conveyor SSEC81.5 represents a cutting-edge solution tailored to fulfill the requirements of the metallurgical sector. It is recognized for its remarkable performance and longevity, making it an ideal option for horizontal conveyor systems utilized in various metallurgical applications.

2. Key Features

2.1 Premium Stainless Steel Material

This cathode chain is made from high-grade stainless steel, which provides outstanding resistance against corrosion, wear, and elevated temperatures. Such material composition ensures extended durability and dependable operation, even in rigorous metallurgical settings.

2.2 Improved Electrolysis Effectiveness

The SSEC81.5 cathode chain leverages a distinctive design along with advanced electrolysis technology to enhance the efficiency of the electrolysis procedure. It promotes seamless electric current flow, optimizing metal deposition while reducing energy losses.

3. Exceptional Durability

Engineered to endure the demanding conditions of metallurgical facilities, the SSEC81.5 cathode chain offers remarkable strength. Its durability leads to minimized maintenance needs and decreased downtime, thereby enhancing productivity and generating cost savings.

4. Customizable Design

4.1 Modular Configuration

The SSEC81.5 cathode chain is designed with a modular structure, facilitating straightforward installation, upkeep, and personalization. Its adaptable framework allows for easy integration with pre-existing horizontal conveyor setups, providing customized solutions for diverse production needs.

4.2 Adjustable Dimensions

This cathode chain accommodates a variety of conveyor widths, offering options for adjustable length. This flexibility ensures a precise fit and optimal functionality, thereby boosting operational efficiency and product excellence.

5. Safety and Environmental Considerations

5.1 Electrolyte Leakage Prevention

Equipped with an efficient sealing mechanism, the SSEC81.5 cathode chain effectively prevents electrolyte leaks during the electrolysis process. This feature contributes to a safer working atmosphere and mitigates the risk of contamination within the production system.

5.2 Environmentally Friendly Materials

The SSEC81.5 cathode chain is produced from eco-friendly materials that adhere to global environmental regulations, reflecting our commitment to sustainability. This ensures minimal environmental impact while upholding product performance and reliability.

6. Applications

This cathode chain is specifically engineered for horizontal conveyor systems in the metallurgical industry. Its versatility and performance render it suitable for a broad array of applications, including:

- Electrolytic refining

- Metal electrowinning

- Electroplating processes

- Electrochemical synthesis

With its outstanding quality and innovative design, the SSEC81.5 cathode chain is an essential component for efficient and reliable metallurgical processes.

Choose Our Stainless Steel Metallurgy Industry Chains

RP Techniek BV, representing Ever-power Group in the Netherlands, proudly offers the Stainless Steel Metallurgical Electrolysis Cathode Chain for Horizontal Conveyor SSEC81.5. Our unique selling points underscore our exceptional quality and superior service that distinguish us from competitors. With robust production capabilities, we ensure our chains conform to the highest industry benchmarks.

Alongside the SSEC81.5 chain, we provide an extensive range of other stainless steel roller chains for various industrial applications, ensuring you find the ideal chain to meet your needs.

At RP Techniek BV, we prioritize customer satisfaction and aim to surpass expectations. Our dedicated team of professionals is focused on delivering reliable solutions and prompt support for all chain-related inquiries. Whether you need customization, technical assistance, or maintenance services, we are here to help you throughout the entire process.

Select our stainless steel metallurgy industry chains and experience the durability, efficiency, and reliability that our products offer. Contact us today to discuss your specific needs and allow us to become your trusted partner for all your chain requirements.

How to Select Suitable Sprockets?

When selecting appropriate sprockets, it is crucial to consider the specific application and the type of chain in use. For the Stainless Steel Metallurgical Electrolysis Cathode Chain for Horizontal Conveyor SSEC81.5, it is advisable to choose a sprocket that corresponds to the chain's size and pitch.

Our company offers a broad array of sprockets, including options made from various materials such as stainless steel, cast iron, and plastic. Available in different tooth counts and bore sizes, our sprockets can accommodate various shaft diameters.

While choosing a sprocket, factors such as operating conditions, load demands, and environmental considerations should be taken into account. Selecting the appropriate sprocket can enhance the performance and longevity of both the chain and sprocket.

Explore our range of sprockets for the Stainless Steel Metallurgical Electrolysis Cathode Chain for Horizontal Conveyor SSEC81.5, and feel free to reach out for assistance in selecting the perfect sprocket for your specific needs.

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...