Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

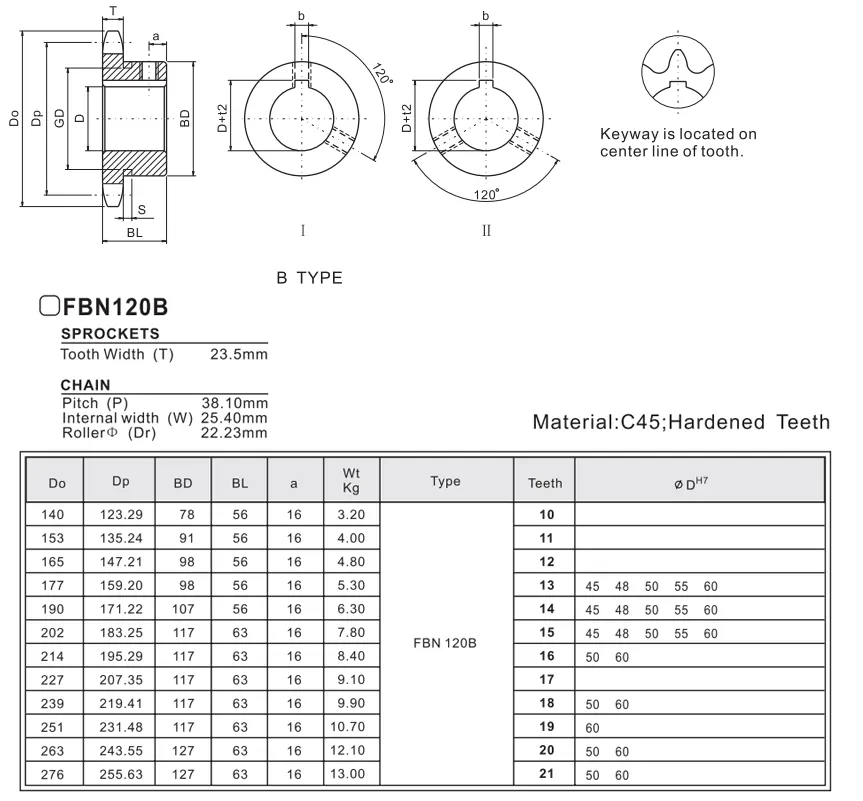

FBN120B Finished Bore Sprocket

The FBN120B Finished Bore Sprocket is engineered for high-performance applications, ensuring durability and efficiency. Designed with precision, this sprocket features a finished bore that allows for easy installation on various machinery. Its robust construction guarantees optimal power transmission, making it an ideal choice for industrial and mechanical systems.

Specifications of FBN120B Finished Bore Sprocket

A finished bore sprocket is a specialized type of sprocket that features a pre-bored hole. This design facilitates straightforward installation onto a shaft, eliminating the need for additional machining processes. Such sprockets are widely utilized across a variety of industrial applications, serving as critical components in machinery and equipment configurations.

Material and Manufacturing Process

We manufacture our finished bore sprockets using high carbon steel, alloy steel, or stainless steel. These materials are chosen for their exceptional strength and durability, ensuring a long service life. The manufacturing process encompasses several stages, including material cutting, punching, forging, and machining methods such as turning, milling, and drilling. Following machining, the sprockets undergo heat treatment, which may involve quenching, tempering, and surface hardening, as well as surface treatment for anti-rust coating. Finally, each sprocket undergoes thorough quality inspection to meet industry standards.

Applications

Finished bore sprockets find application in a multitude of industries and scenarios, including but not limited to:

- Heavy machinery and equipment, where reliability is critical

- Food processing and packaging, maintaining hygiene and efficiency

- Chemical and pharmaceutical industries, demanding precision and durability

- Assembly lines, ensuring seamless operation

- Logistics and warehousing, optimizing material handling processes

Maintenance

To preserve the longevity and peak performance of sprockets, proper maintenance practices are essential. Here are some important maintenance actions to consider:

- Conduct daily inspections to identify any signs of damage or wear

- Perform regular cleaning to eliminate dirt and debris accumulation

- Apply lubrication to minimize friction and prevent corrosion

- Make adjustments and calibrate for accurate alignment

Throughout the lifecycle of a sprocket, several common problems may arise, such as tooth skipping, breakage, wear, excessive noise, and chain slippage. Here are some tailored solutions for each issue:

- Tooth skipping: Assess for misalignment or a worn-out chain; realign or replace as necessary

- Breakage: Inspect for material defects or overload conditions; replace with a new sprocket if needed

- Wear: Regularly monitor the wear on sprockets; replace when teeth show significant wear

- Excessive noise: Clean and lubricate, while ensuring proper alignment between the sprocket and chain

- Chain slippage: Adjust the tension and alignment of the chain and consider replacement if issues persist

Other Types of Sprockets and Chains

Beyond the FBN120B Finished Bore Sprocket, we also provide a diverse array of other sprocket types, including taper lock sprockets, QD sprockets, and idler sprockets, along with a comprehensive selection of chains to cater to various application needs.

Sprockets Supplier in the Netherlands

RP Techniek BV acts as the sales representative for Ever-power Group in the Netherlands, offering a broad spectrum of high-quality sprockets tailored to meet distinct industrial demands. Among our top products is the FBN120B Finished Bore Sprocket, engineered for reliability and efficiency in power transmission applications. This sprocket is designed to deliver optimal performance, making it well-suited for a variety of machinery types.

In addition to our standard offerings, we take pride in our ability to provide custom solutions tailored to specific customer requirements. We invite all clients to share their designs and samples for unique solutions that align with their individual needs.

Additional information

| Edited | Zqq |

|---|

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...