Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

Specifications

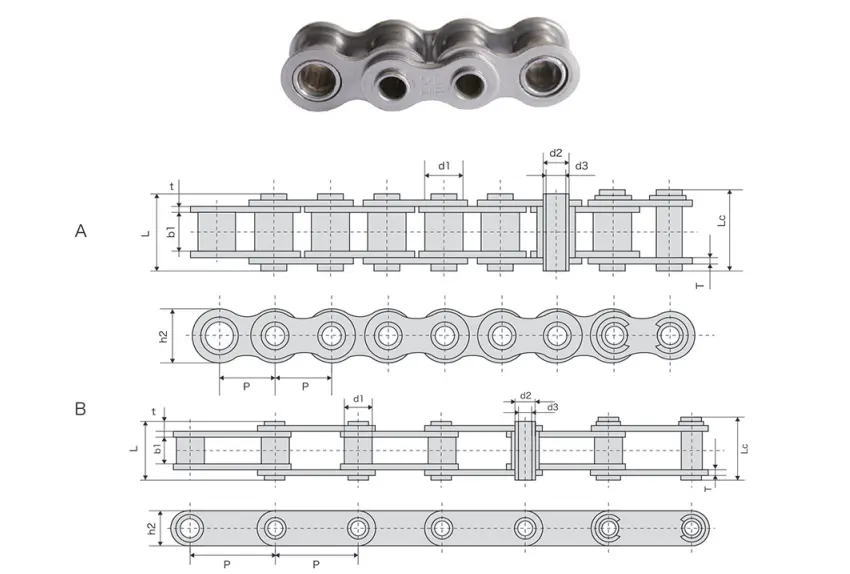

The 60HPSS Stainless Steel Hollow Pin Chain comes with the following specifications:

- Material: Stainless Steel

- Type: Hollow Pin Chain

- Strength: 60HPSS

| Chain No |

Pitch | Bush? diameter | Width between inner plates |

Pin diameter |

Pin diameter |

Pin length |

Pin length |

Inner plate depth |

Plate thickness |

Breaking Load |

Weight per meter |

Type |

| P | d1 | bl | d2 | d3 | L | LC | h2 | T | Q | q | ||

| max | min | max | min | max | max | max | max | min | ||||

| mm | mm | mm | mm | mm | Mm | mm | mm | mm | KN | kg/m | ||

| 08BHPFSS | 12.7 | 8.51 | 7.75 | 6.55 | 4.5 | 16.4 | 17.6 | 11.8 | 1.5 | 7.8/1773 | 0.57 | A |

| 40HPSS | 12.7 | 7.95 | 7.85 | 5.63 | 4 | 16.5 | 17.6 | 12 | 1.5 | 7.7/1750 | 0.55 | A |

| 50HPSS | 15.875 | 10.16 | 9.4 | 7.03 | 5.13 | 20.7 | 21.9 | 15.09 | 2 | 14.0/3182 | 0.92 | A |

| 60HPSS | 19.05 | 11.91 | 12.7 | 8.31 | 6 | 25.8 | 26.8 | 18 | 2.4 | 16.8/3818 | 1.31 | A |

| *12BHPSS | 19.05 | 12.07 | 11.68 | 6.5 | 4 | 21.6 | 22.8 | 15.9 | 1.8 | 16.5/3750 | 1.1 | A |

| 80HPSS | 25.4 | 15.88 | 15.75 | 11.4 | 8.05 | 32.5 | 33.8 | 24 | 3 | 35.0/7955 | 2.29 | A |

| C2040HPSS | 25.4 | 7.95 | 7.85 | 5.63 | 4 | 16.5 | 17.6 | 12 | 1.5 | 7.7/1750 | 0.47 | B |

| C2050HPSS | 31.75 | 10.16 | 9.4 | 7.22 | 5.12 | 20.5 | 21.8 | 15 | 2 | 14.3/3250 | 0.77 | B |

| C2060HPSS | 38.1 | 11.91 | 12.7 | 8.31 | 6 | 25.8 | 26.8 | 17 | 2.4 | 16.8/3818 | 1.03 | B |

| C2080HPSS | 50.8 | 15.88 | 15.75 | 11.4 | 8.05 | 32.5 | 33.8 | 24 | 3 | 35.0/7955 | 1.83 | B |

| *HB50.8SS | 50.8 | 30 | 10.5 | 11.4 | 8.2 | 27.4 | 28.6 | 26 | 3 | 35.0/7955 | 2.6 |

Introduction

The 60HPSS Stainless Steel Hollow Pin Chain is a robust and long-lasting chain designed for various industrial usages. Crafted from premium stainless steel, it is highly resistant to rust and can endure challenging environments. Additionally, the hollow pin feature contributes to a lighter weight, making it simpler to manage.

Features and Benefits

1. Corrosion Resistance

A standout aspect of the 60HPSS Stainless Steel Hollow Pin Chain is its ability to resist corrosion. Constructed from high-quality stainless steel, this chain can endure exposure to harsh chemicals and environments without succumbing to rust or degradation over time. This makes it a perfect option for applications where corrosion protection is essential.

2. Hollow Pin Design

The hollow pin structure is another significant advantage of this chain. Utilizing hollow pins instead of solid ones decreases the chain's weight while preserving its strength. This characteristic enhances ease of handling and movement, which can minimize workplace injuries and boost productivity in industrial settings.

3. Durability

The 60HPSS Stainless Steel Hollow Pin Chain boasts impressive durability. Its construction from high-quality stainless steel allows it to handle considerable loads and constant operation without breaking or wearing out. This makes it a dependable choice for rigorous industrial applications.

4. Versatility

This chain's versatility is one of its primary benefits. It is appropriate for a broad array of industrial uses, ranging from conveyor systems to material handling machinery. Its strength, durability, and corrosion resistance make it the ideal selection for harsh environments where other chains may fail.

5. Easy to Maintain

Lastly, maintaining the 60HPSS Stainless Steel Hollow Pin Chain is straightforward. Its uncomplicated design and high-quality fabrication make it easy to clean and lubricate, helping to prolong its lifespan and minimize downtime due to maintenance concerns.

Conclusion

The 60HPSS Stainless Steel Hollow Pin Chain stands out as a high-quality and durable chain suited for a wide range of industrial applications. Its resistance to corrosion, hollow pin design, durability, versatility, and ease of maintenance all contribute to its suitability for demanding environments where other chains might not be effective. For those seeking a reliable and high-quality chain for industrial needs, the 60HPSS Stainless Steel Hollow Pin Chain is an excellent option.

Choose Our Stainless Steel Roller Chains

RP Techniek BV represents Ever-power Group in the Netherlands. We proudly offer the outstanding 60HPSS Stainless Steel Hollow Pin Chain, exemplifying our unique selling points. Our stainless steel roller chains are celebrated for their exceptional quality, superior service, and remarkable durability. With robust production capabilities, we guarantee that each chain meets stringent standards. Alongside the 60HPSS chain, we also offer a broad spectrum of other stainless steel roller chains to meet various requirements. Opt for us for dependable, top-quality roller chains that will surpass your expectations.

Sprockets for Sale

When searching for the perfect complement to your 60HPSS Stainless Steel Hollow Pin Chain, our company provides an extensive selection of sprockets for sale. Whether you require a standard roller chain sprocket, double pitch sprocket, or a custom sprocket, we have the right solution for you.

Our sprockets are crafted from high-quality materials to ensure longevity and peak performance. Precision-engineered, they deliver reliable and efficient power transmission. With our vast inventory, you can find the appropriate size, tooth count, and bore size tailored to your specific needs.

By selecting our sprockets, you can anticipate smooth and precise chain engagement, which reduces wear and extends the lifespan of your chain. Our sprockets are designed to withstand demanding applications, such as heavy-duty industrial machinery, conveyor systems, and agricultural equipment.

Explore our diverse selection of sprockets below:

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...