Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

Specifications of 50HPSS Stainless Steel Hollow Pin Chain

- Material: Stainless steel

- Type: Hollow pin chain

- Pitch: 0.750 inches

- Working Load: 4,540 pounds

- Breaking Load: 10,120 pounds

- Pin Diameter: 0.250 inches

- Inner Width: 0.875 inches

- Weight per Foot: 1.90 pounds

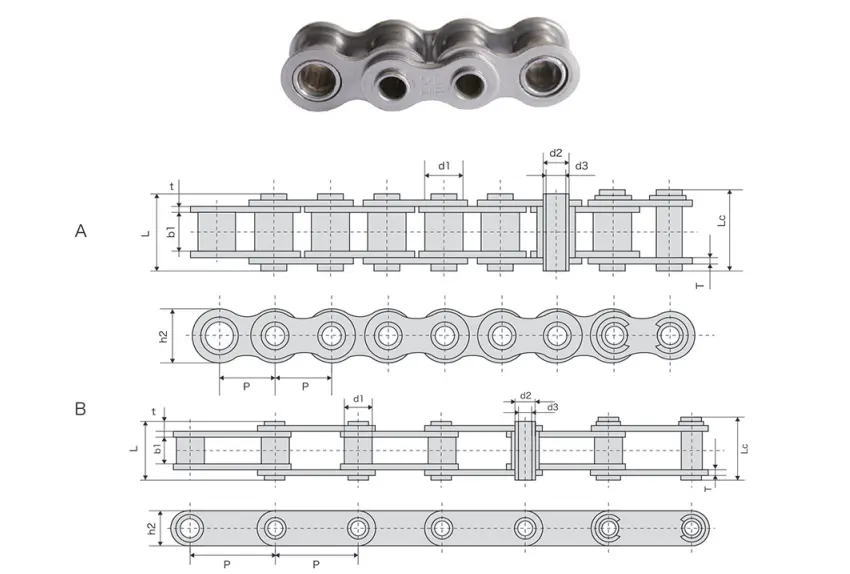

| Chain No |

Pitch | Bush? diameter | Width between inner plates |

Pin diameter |

Pin diameter |

Pin length |

Pin length |

Inner plate depth |

Plate thickness |

Breaking Load |

Weight per meter |

Type |

| P | d1 | bl | d2 | d3 | L | LC | h2 | T | Q | q | ||

| max | min | max | min | max | max | max | max | min | ||||

| mm | mm | mm | mm | mm | Mm | mm | mm | mm | KN | kg/m | ||

| 08BHPFSS | 12.7 | 8.51 | 7.75 | 6.55 | 4.5 | 16.4 | 17.6 | 11.8 | 1.5 | 7.8/1773 | 0.57 | A |

| 40HPSS | 12.7 | 7.95 | 7.85 | 5.63 | 4 | 16.5 | 17.6 | 12 | 1.5 | 7.7/1750 | 0.55 | A |

| 50HPSS | 15.875 | 10.16 | 9.4 | 7.03 | 5.13 | 20.7 | 21.9 | 15.09 | 2 | 14.0/3182 | 0.92 | A |

| 60HPSS | 19.05 | 11.91 | 12.7 | 8.31 | 6 | 25.8 | 26.8 | 18 | 2.4 | 16.8/3818 | 1.31 | A |

| *12BHPSS | 19.05 | 12.07 | 11.68 | 6.5 | 4 | 21.6 | 22.8 | 15.9 | 1.8 | 16.5/3750 | 1.1 | A |

| 80HPSS | 25.4 | 15.88 | 15.75 | 11.4 | 8.05 | 32.5 | 33.8 | 24 | 3 | 35.0/7955 | 2.29 | A |

| C2040HPSS | 25.4 | 7.95 | 7.85 | 5.63 | 4 | 16.5 | 17.6 | 12 | 1.5 | 7.7/1750 | 0.47 | B |

| C2050HPSS | 31.75 | 10.16 | 9.4 | 7.22 | 5.12 | 20.5 | 21.8 | 15 | 2 | 14.3/3250 | 0.77 | B |

| C2060HPSS | 38.1 | 11.91 | 12.7 | 8.31 | 6 | 25.8 | 26.8 | 17 | 2.4 | 16.8/3818 | 1.03 | B |

| C2080HPSS | 50.8 | 15.88 | 15.75 | 11.4 | 8.05 | 32.5 | 33.8 | 24 | 3 | 35.0/7955 | 1.83 | B |

| *HB50.8SS | 50.8 | 30 | 10.5 | 11.4 | 8.2 | 27.4 | 28.6 | 26 | 3 | 35.0/7955 | 2.6 |

Introduction

The 50HPSS stainless steel hollow pin chain is a specialized roller chain constructed from stainless steel. It is engineered to endure harsh conditions, especially in environments with moisture, chemicals, and elevated temperatures. This chain is applicable across various sectors, such as food processing, packaging, and pharmaceuticals.

Construction

This 50HPSS chain is made up of various components, including pins, rollers, inner plates, and outer plates. The hallmark of this chain is its hollow pins, which facilitate quick installation and removal. The rollers play a crucial role in maintaining chain tension and minimizing friction. The inner and outer plates secure the pins and rollers effectively.

Features

- Constructed from stainless steel for resistance to corrosion and long-lasting durability.

- Features hollow pins that enable straightforward installation and disassembly.

- Offered in multiple chain sizes to accommodate various applications.

- Can be tailored with attachments to fulfill specific requirements.

- Simplified maintenance and cleaning process, leading to reduced downtime.

Applications

The 50HPSS chain is well-suited for diverse applications, including:

- Food processing and packaging.

- Beverage manufacturing and bottling.

- Pharmaceutical production.

- Chemical processing.

- Water treatment facilities.

Maintenance and Lubrication

To ensure optimal functionality and durability, the 50HPSS chain requires consistent maintenance and lubrication. Regular inspections for wear and damage are essential, and any faulty components should be replaced promptly. Lubrication should utilize a high-quality lubricant compatible with stainless steel chains, while over-lubrication should be avoided to prevent environmental contamination.

Conclusion

The 50HPSS stainless steel hollow pin chain stands out as a dependable and resilient chain option, ideal for extreme conditions. Its distinctive design, resistance to corrosion, and ease of installation render it a preferred choice for a variety of applications, particularly where exposure to moisture, chemicals, and high temperatures is a concern.

Choose Our Stainless Steel Roller Chains

RP Techniek BV serves as the official sales representative for Ever-power Group in the Netherlands. We proudly offer the 50HPSS Stainless Steel Hollow Pin Chain, recognized for its unique attributes such as superior quality, excellent service, and remarkable durability. Our manufacturing capabilities, coupled with our industry experience, have positioned us as a trustworthy brand.

Our 50HPSS Stainless Steel Hollow Pin Chain is crafted to comply with the highest industry standards and is capable of withstanding demanding environments. The premium stainless steel material guarantees corrosion resistance and exceptional performance. We also have a variety of other stainless steel roller chains available, each featuring distinctive characteristics suited for different applications.

Our dedication to quality, client satisfaction, and innovation has established us as a dependable leader in the stainless steel roller chain market. Our products are widely utilized across various industries, including food processing, automotive, and agriculture.

We take pride in delivering exceptional service and support to our clients, ensuring they receive the right product precisely when they need it. Our technical team is always ready to provide solutions and assistance for any challenges our clients may encounter.

Sprockets for Sale

To find the perfect complement for your 50HPSS Stainless Steel Hollow Pin Chain, consider our extensive selection of sprockets. We provide various sprocket types designed specifically to enhance the performance of your chain.

Our sprockets are crafted with the highest precision and quality, guaranteeing exceptional durability and reliability. Whether you require a standard sprocket, a custom option, or a specialized design, we are here to assist.

We take pride in our diverse assortment of sprockets catering to a variety of industrial needs. From single-strand to multi-strand sprockets, our comprehensive stock accommodates numerous chain configurations.

When you choose our sprockets, you can expect smooth and efficient power transmission, reduced wear on your chain, and improved overall performance. We understand the necessity of selecting the appropriate sprocket for your specific application, and our knowledgeable team is available to help you make the ideal choice.

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...