In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

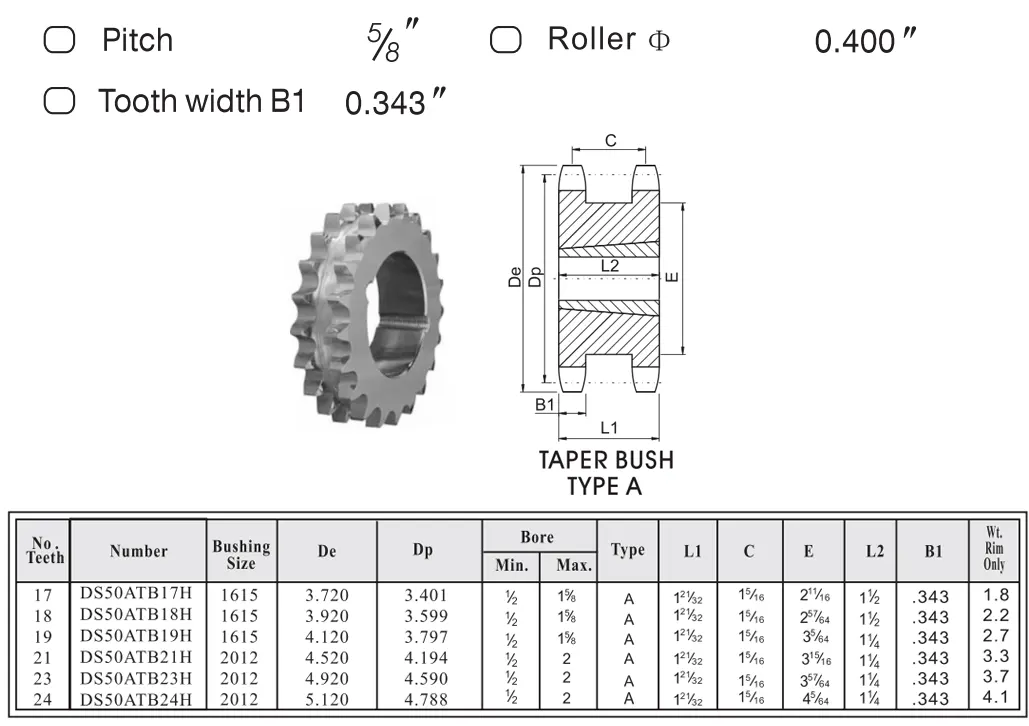

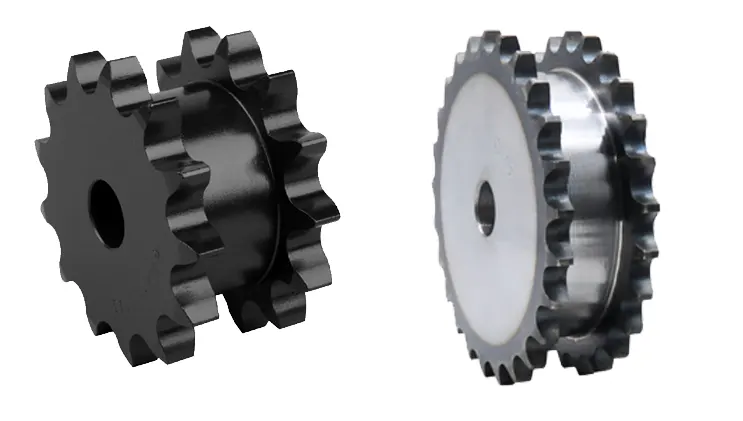

50 Taper Bushed Type Double Single Sprocket

The 50 Taper Bushed Type Double Single Sprocket is designed for durability and efficiency in power transmission systems. Engineered with precision, it features a taper bush design for easy installation and maintenance. Ideal for various machinery applications, this sprocket ensures reliable performance and optimal compatibility with standard chains, enhancing operational efficiency.

Specifications of 50 Taper Bushed Type Double Single Sprocket

Design Features of 50 Taper Bushed Type Double Single Sprocket

The 50 Taper Bushed Type Double Single Sprocket showcases an innovative design capable of accommodating two single-row chains simultaneously. This dual-chain arrangement facilitates concurrent drive engagement, which significantly boosts both flexibility and efficiency in power transmission applications. Employing taper bushed technology guarantees secure mounting along with effortless adjustments. Operating two chains at the same time not only enhances functional efficiency but also prolongs the lifespan of the components, making this sprocket highly suitable for a variety of applications across different industries.

Surface Treatment of 50 Taper Bushed Type Double Single Sprocket

The surface treatment procedure for the 50 Taper Bushed Type Double Single Sprocket encompasses several crucial steps aimed at improving its wear resistance and prolonging its operational lifespan. The process begins with a meticulous cleaning phase to eliminate any contaminants. Subsequently, a protective coating is applied, forming a barrier against corrosion and wear. This is followed by a curing phase to ensure the coating adheres effectively to the sprocket. Finally, a comprehensive quality inspection is conducted to assess the durability and performance of the surface treatment, ensuring the sprocket remains reliable even under demanding working conditions.

Application Areas of 50 Taper Bushed Type Double Single Sprocket

The 50 Taper Bushed Type Double Single Sprocket is engineered to meet various challenges across multiple industries:

- Power transmission systems in manufacturing equipment.

- Automated conveyor setups to enhance material handling efficiency.

- Heavy-duty functions in agricultural machinery.

- Robotic mechanisms that require accurate motion control.

- Transportation sectors seeking dependable drivetrain solutions.

Optimized Sprocket Spacing Design

The 50 Taper Bushed Type Double Single Sprocket incorporates a carefully designed sprocket spacing system that guarantees optimal chain clearance. This thoughtful design minimizes potential interference among components, resulting in smooth functionality and improved efficiency. By ensuring the ideal spacing between sprockets, the likelihood of chain rubbing or misalignment is significantly reduced. This meticulous attention to spacing not only extends the lifespan of both the chain and sprocket system but also enhances the overall reliability of the machinery in which it operates.

Double Single Sprockets Supplier

RP Techniek BV serves as a leading sales agent in the Netherlands, proudly ranking among the top suppliers of sprockets. Our comprehensive product range includes the 50 Taper Bushed Type Double Single Sprocket, meticulously designed for both efficiency and durability across varied applications. This sprocket type is particularly suited for heavy-duty tasks, ensuring dependable operation in rigorous environments.

At RP Techniek BV, we prioritize customer satisfaction by delivering outstanding service, which includes expert guidance, prompt delivery, and tailored support to cater to your specific requirements.

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...