In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

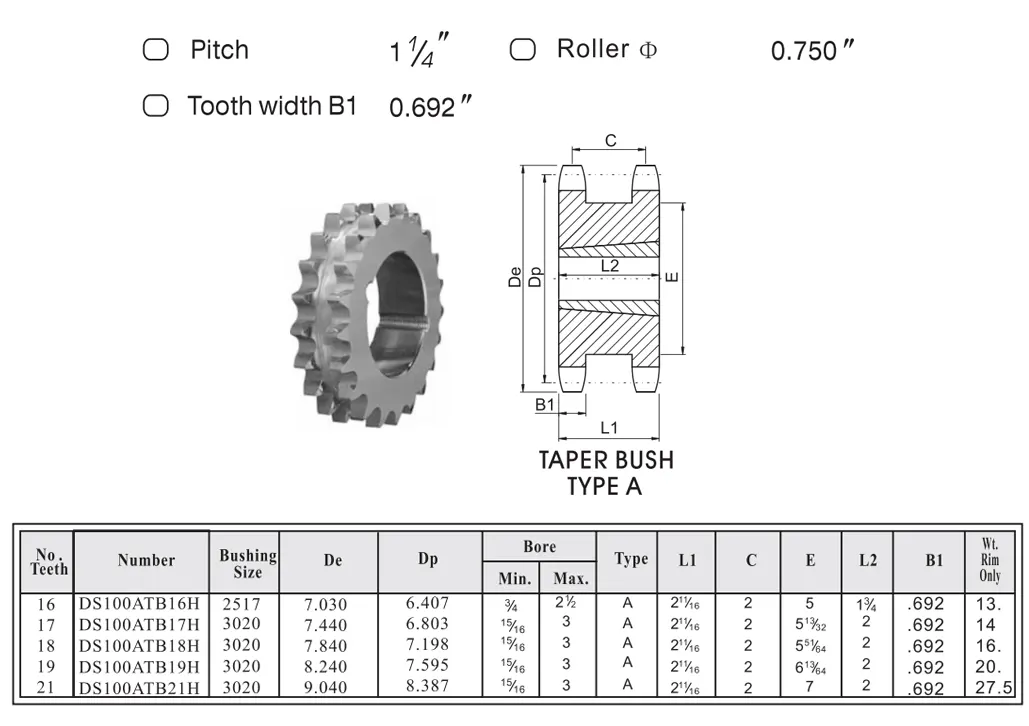

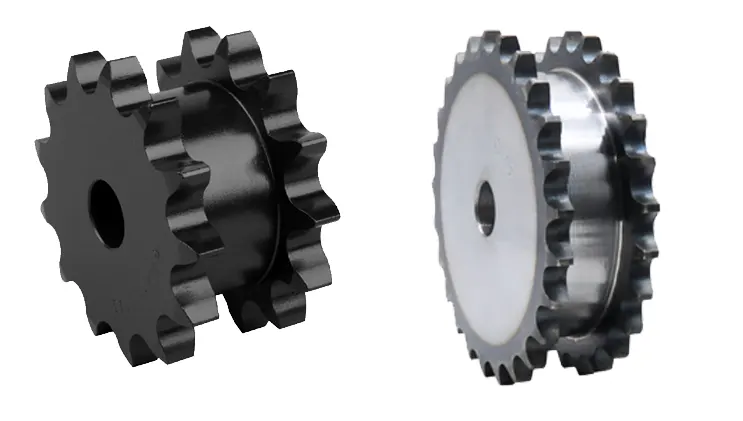

100 Taper Bushed Type Double Single Sprocket

The 100 Taper Bushed Type Double Single Sprocket is a robust and versatile component designed for efficient power transmission in various machinery applications. Its tapered design allows for easy installation and removal, while the dual sprocket setup ensures smooth operation and enhanced durability, making it ideal for both industrial and commercial use.

Specifications of 100 Taper Bushed Type Double Single Sprocket

Design Features of 100 Taper Bushed Type Double Single Sprocket

The 100 Taper Bushed Type Double Single Sprocket is meticulously designed to drive two single-row chains concurrently, thereby boosting operational flexibility and overall efficiency. Its innovative dual-chain structure facilitates synchronized movement, which helps in reducing wear and tear while optimizing the power transmission process. This unique configuration also diminishes slack and maintains a consistent tension, resulting in smoother functioning and enhanced performance across various applications. The sturdy construction of this sprocket significantly contributes to its durability, establishing it as a dependable option for demanding environments.

Surface Treatment of 100 Taper Bushed Type Double Single Sprocket

The surface treatment process for the 100 Taper Bushed Type Double Single Sprocket consists of several crucial steps aimed at improving its durability and wear resistance. Initially, the sprocket undergoes a comprehensive cleaning to eliminate any contaminants that may affect its performance. Following this, a hardening treatment is applied using heat or chemical processes, which creates a tougher surface layer. Subsequently, a protective coating, such as zinc plating or powder coating, is applied to guard against corrosion. Lastly, the sprocket undergoes a quality assurance inspection. This thorough process plays a significant role in extending the sprocket's lifespan and ensuring reliable performance across a variety of applications.

Application Areas of 100 Taper Bushed Type Double Single Sprocket

The 100 Taper Bushed Type Double Single Sprocket is crafted to meet diverse industrial requirements and applications, such as:

- Power transmission systems utilized in manufacturing machinery.

- Conveyor belts that enable efficient material handling processes.

- Automated production lines that demand precise synchronization.

- Agricultural machinery designed for improved performance.

- Mining and construction equipment that require durability and reliability.

Its robust design guarantees optimal functionality in these sectors, making it a versatile solution for various operational challenges.

Optimized Sprocket Spacing Design

The 100 Taper Bushed Type Double Single Sprocket incorporates an advanced sprocket spacing design that ensures optimal clearance for the chains. This innovative design significantly reduces the likelihood of chain interference, allowing for seamless operation even when subjected to high loads. By maintaining precise distances between the sprockets, it effectively lowers wear and prolongs the longevity of both the sprocket and the chain. This careful attention to spacing ultimately contributes to enhanced performance and reliability, making it suitable for a wide range of applications.

Double Single Sprockets Supplier

RP Techniek BV is a prominent supplier in the Netherlands, known for representing the Ever-power Group. We take pride in our position as one of the leading sprocket suppliers in the country. Our extensive product range includes the 100 Taper Bushed Type Double Single Sprocket, engineered for superior performance and longevity across various applications. This sprocket is designed to optimize torque transmission and is compatible with multiple chain sizes, making it adaptable for different types of machinery.

At RP Techniek BV, we prioritize delivering exceptional service and support to our clients. Our dedicated team is committed to helping you find the right sprocket to meet your specific requirements, and we ensure prompt delivery along with expert assistance to guarantee your complete satisfaction.

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...