Washdown worm gear reducers are an essential component of bakery equipment in Amsterdam. These machines, which are used to mix and knead dough, require precise and reliable gearing to ensure optimal performance. In this article, we will explore the features, benefits, and applications of washdown worm gear reducers, as well as their installation and maintenance.

Features of Washdown Worm Gear Reducers

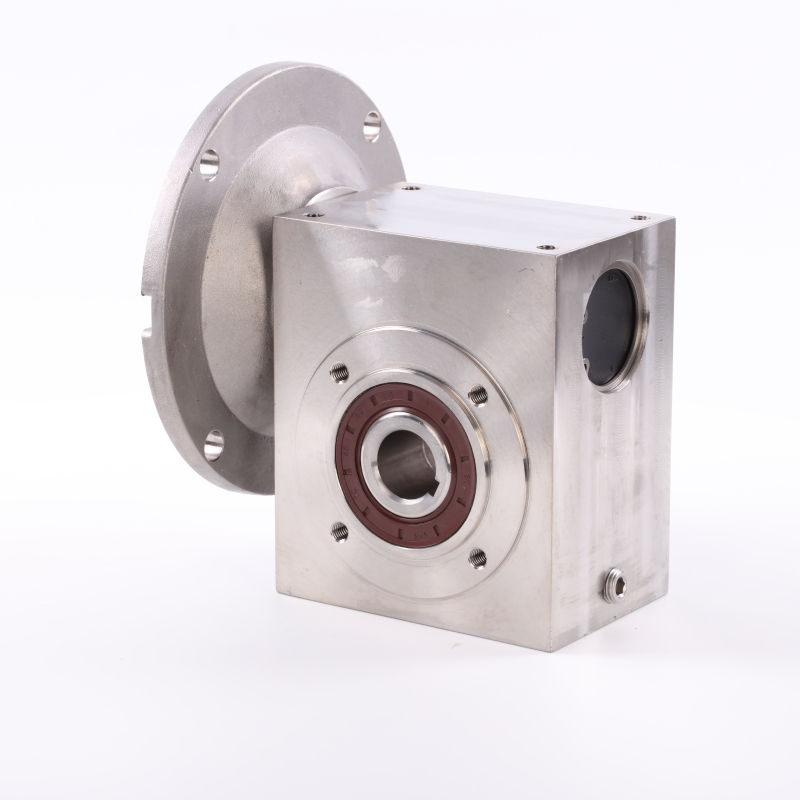

Washdown worm gear reducers are designed to withstand harsh operating conditions, including exposure to water, chemicals, and high temperatures. They are typically made of stainless steel, which is corrosion-resistant and easy to clean. The gearing system consists of a worm gear and a worm wheel, which work together to provide high torque and low speed rotation. The housing is sealed to prevent water and debris from entering the gearbox.

Benefits of Washdown Worm Gear Reducers

Washdown worm gear reducers offer several benefits for bakery equipment in Amsterdam. Firstly, they provide high torque at low speeds, which is essential for mixing and kneading dough. Secondly, they are highly durable and resistant to corrosion, which ensures a long lifespan and low maintenance costs. Thirdly, they are easy to clean and sanitize, which is critical for maintaining food safety standards. Finally, they are compact and efficient, which allows for easy integration into various bakery equipment designs.

Applications of Washdown Worm Gear Reducers

Washdown worm gear reducers are widely used in bakery equipment in Amsterdam, including mixers, kneaders, and dough sheeters. They are also used in other food processing equipment, such as meat grinders and sausage stuffers. Additionally, they are used in various industries that require washdown and corrosion-resistant gearing, such as pharmaceuticals and chemical processing.

Installation of Stainless Steel Worm Gear Reducers and Motors

The installation of stainless steel worm gear reducers and motors requires proper planning and execution. Firstly, the gearbox and motor must be properly aligned to ensure optimal performance and efficiency. Secondly, the motor must be protected from water and other contaminants, which can cause damage and reduce lifespan. Thirdly, the wiring and electrical connections must be properly installed and grounded to ensure safety and compliance with regulations. Finally, regular maintenance and inspection are required to ensure the gearbox and motor are functioning correctly.

Common Problems and Solutions

| Problem | Solution |

|---|---|

| Leaking oil or grease | Check for damaged seals and replace if necessary. Clean and refill with appropriate lubricant. |

| Overheating | Check for blocked ventilation and clean if necessary. Reduce load on gearbox if possible. |

| Noisy operation | Check for worn or damaged gears and replace if necessary. Check for proper lubrication. |

| Reduced performance | Check for misalignment or worn gears and replace if necessary. Check for proper lubrication and ventilation. |

| Electrical issues | Check for loose connections and faulty wiring. Repair or replace as necessary. |

Stainless Steel Geared Motors for Sale

Stainless steel geared motors are a critical component of bakery equipment in Amsterdam. They work in tandem with the washdown worm gear reducers to provide precise and reliable torque for mixing and kneading dough. At RP Techniek BV, we offer a wide range of stainless steel geared motors for sale, including AC and DC motors with various power ratings and speed controls. Our motors are designed for optimal performance in washdown environments and are highly durable and corrosion-resistant.

About Us

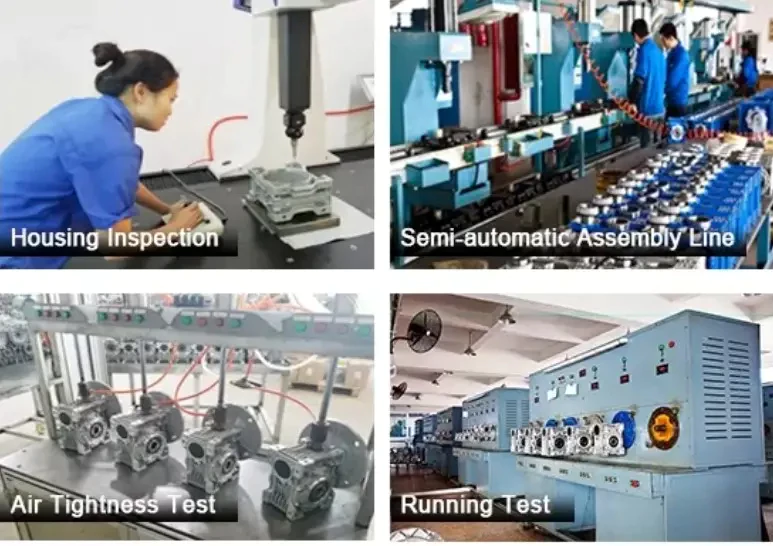

RP Techniek BV is the sales agent for Ever-power Group in the Netherlands, specializing in the production and distribution of washdown worm gear reducers and other industrial equipment. Our products are designed to meet the highest standards of quality, durability, and performance, and are widely used in various industries throughout Europe and North America. Our customers include some of the biggest names in food processing, pharmaceuticals, and chemical manufacturing. We take pride in our commitment to customer satisfaction, and we strive to provide the best possible service and support to our clients.

If you are interested in learning more about our products, please visit our website or contact us directly for more information. We look forward to working with you!

Q&A

Q: What is the maximum operating temperature for washdown worm gear reducers?

A: The maximum operating temperature for washdown worm gear reducers varies depending on the specific model and application. Generally, these reducers can withstand temperatures up to 180°C without experiencing any significant degradation in performance or lifespan.

Q: Can washdown worm gear reducers be used in other industries besides food processing?

A: Yes, washdown worm gear reducers are widely used in other industries that require corrosion-resistant and washdown gearing, such as pharmaceuticals, chemical processing, and marine applications.

Q: How often should washdown worm gear reducers be cleaned and sanitized?

A: Washdown worm gear reducers should be cleaned and sanitized according to the manufacturer's recommendations and industry standards. In general, they should be cleaned and sanitized after each use to prevent the buildup of bacteria and other contaminants.

Q: Do you offer custom design and fabrication services for washdown worm gear reducers?

A: Yes, we offer custom design and fabrication services for washdown worm gear reducers and other industrial equipment. Our team of engineers and technicians can work with you to develop a customized solution that meets your specific requirements and specifications.

Q: What is the warranty period for washdown worm gear reducers?

A: The warranty period for washdown worm gear reducers varies depending on the specific model and manufacturer. Generally, they come with a one-year warranty that covers defects in materials and workmanship.

Edited by: Zqq.