Stainless Steel Worm Gear Reducers

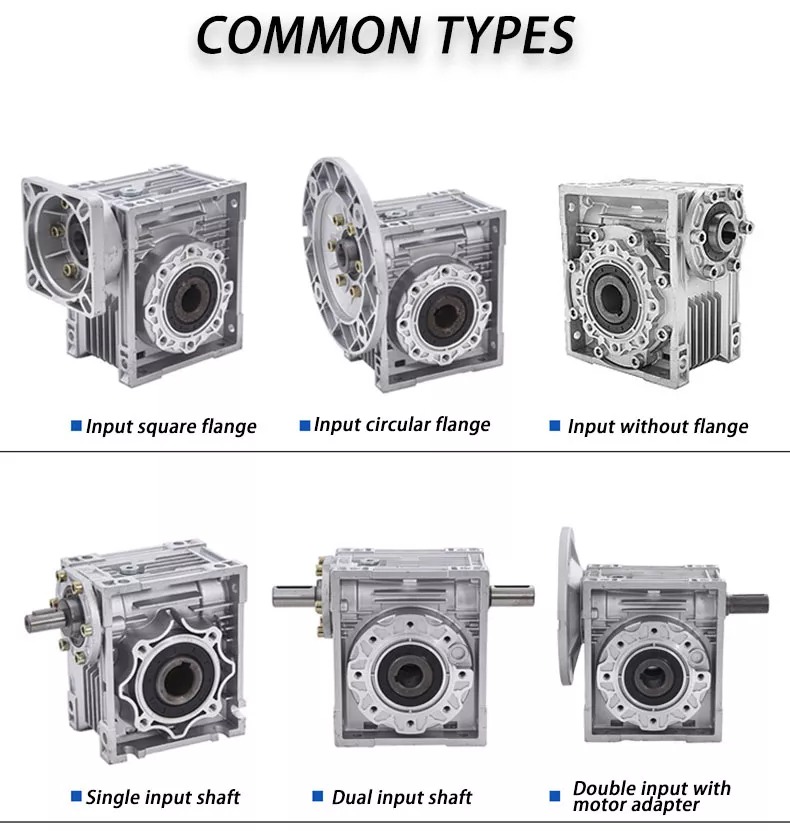

Stainless Steel Worm Gear Reducers Selection

Stainless Steel Worm Gear Reducer Features

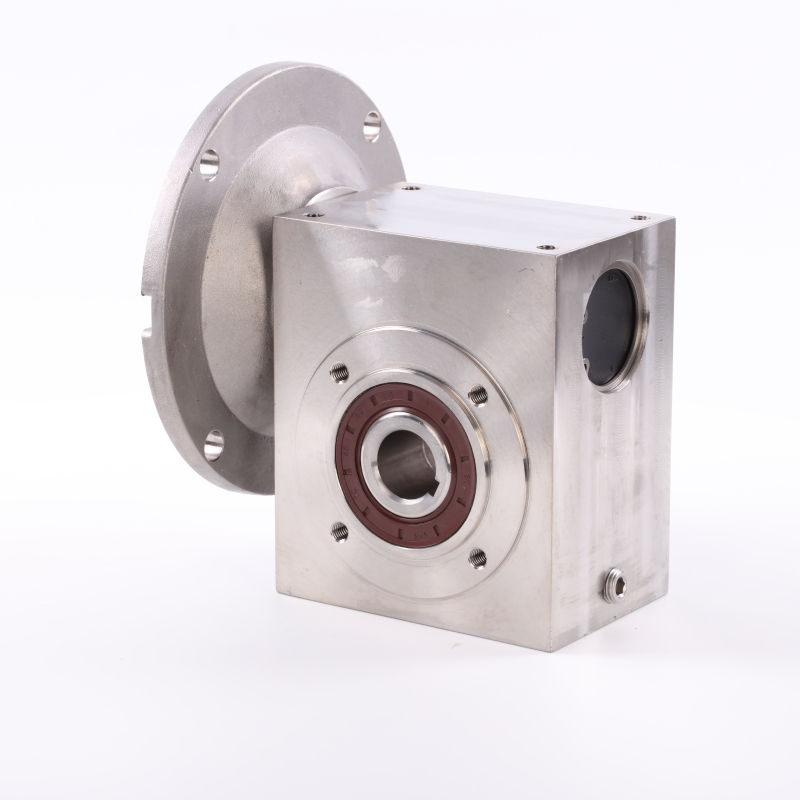

- SSRV Series Stainless Steel Worm Gear Reducer

- Precision-cast 304 stainless steel housing and wheel core.

- 12-2 tin bronze worm wheel and fully synthetic worm gear oil.

- Electropolished surface for corrosion resistance and easy cleaning.

- Offers a wide range of gear ratios, high torque, and multi-directional installation.

- Available in models 40, 50, 63, 75, and 90.

- GMSS Series Stainless Steel Gear Reducer

- 304 precision-cast stainless steel housing.

- 12-2 tin bronze worm wheel and 304 material for the wheel core.

- Fully synthetic worm gear oil for smooth operation.

- Six sides of the housing processed for a sleek design and easy cleaning.

- Available in models 30, 40, 50, 63, 75, and 90.

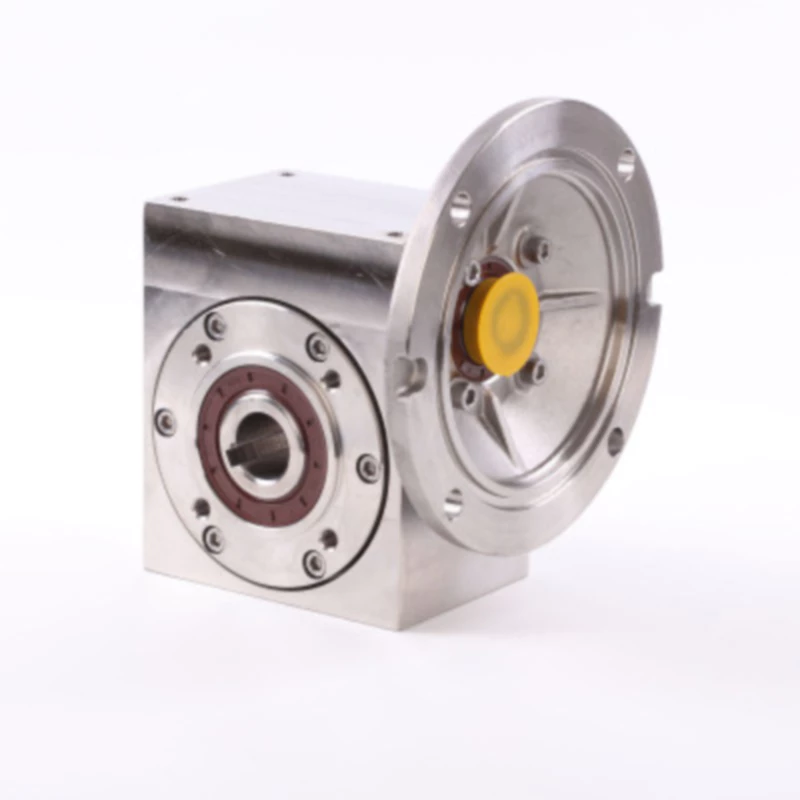

- SSVF Series Stainless Steel Worm Gear Reducer

- Compact design with precision-cast 304 stainless steel housing.

- 304 material for the wheel core and 12-2 tin bronze worm wheel.

- Fully synthetic worm gear oil and electropolished surface.

- Excellent corrosion resistance, ease of cleaning, and a variety of gear ratios.

- Available in models 40, 50, and 63.

Stainless Washdown Worm Gear Reducer for Sale

Stainless steel worm gear reducers are widely used in the food industry. These food-safe motors, including worm gearmotors, are especially ideal for sectors like meat, poultry, fish, and dairy, where there is a high risk of contamination.

Our Stainless Steel washdown drive worm gearboxes offer exceptional value, featuring hollow output bores. We also provide stainless steel bushing kits for larger head shaft sizes. These worm gears come in various sizes and configurations and can be customized to fit your specific requirements. If you need a stainless steel worm gear reducer for a particular application, we can assist. As a leading gearbox manufacturer specializing in mechanical transmission, we are dedicated to providing custom solutions to meet your unique needs.

Characteristics of Stainless Steel Worm Gearboxes

- Corrosion Resistance: Built from high-grade stainless steel (typically SS304 or SS316), ensuring longevity in corrosive environments.

- Sealed Design: Fully enclosed housings to protect internal components from water, chemicals, and contaminants.

- Smooth Surfaces: Designed to prevent the accumulation of bacteria, ideal for maintaining hygiene in food and pharmaceutical applications.

- High-Pressure Washdown Capable: Withstands cleaning with high-pressure hoses, making them suitable for environments that require rigorous cleaning protocols.

- High Efficiency: Our washdown worm gearboxes are engineered to minimize friction and deliver maximum output with minimal energy loss.

- Low Maintenance: Stainless steel construction requires minimal upkeep, saving you time and operational costs.

- Multiple Configurations: Available in various sizes and gear ratios to suit your specific needs.

Stainless Steel Washdown Worm Gearboxes Materials

Stainless steel washdown worm gearboxes are used where cleanliness and corrosion resistance are crucial. The materials used in these gearboxes are carefully selected to ensure durability, hygiene, and resistance to corrosion. Here are the common materials used in their construction:

Stainless Steel (Housing)

Material: Typically SS304 or SS316 stainless steel.

These materials provide excellent corrosion resistance and are suitable for environments with frequent washdowns, exposure to chemicals, or food contact. SS316 is especially effective in resisting pitting and corrosion in saline or acidic conditions. These materials are used for the gearbox housing and external components to ensure hygiene and protection against contaminants.

Bronze or Phosphor Bronze (Worm Gear)

Material: Bronze alloys, such as phosphor bronze.

Bronze is commonly used for worm gears because of its good wear resistance and low friction when meshing with the steel worm, which provides smooth and efficient transmission of power and reduces wear and tear, improving the gearbox's lifespan.

Hardened Steel (Worm Shaft)

Material: Case-hardened or nitrided steel.

Hardened steel has excellent strength and durability, making it suitable for handling the high loads and stresses in worm gear applications. The worm shaft is typically made from this material to ensure longevity and resistance to wear, even under high pressure.

Food-Grade Seals (Gaskets and Seals)

Material: FDA-approved rubber or elastomers, such as EPDM, Silicone, or Viton.

These materials resist degradation from cleaning agents, chemicals, and high temperatures while maintaining a tight seal to prevent contamination, which ensures the worm gearbox is protected from ingress of water, chemicals, and food particles during washdowns.

Food-Grade Lubricants

Material: NSF H1-approved food-grade lubricants.

These lubricants are non-toxic and safe for incidental food contact, making them ideal for gearboxes used in food processing environments.sed inside the gearbox to reduce friction and wear between components while ensuring safety in food and pharmaceutical applications.

Stainless Steel Bushing Kits (For Shafts)

Material: Stainless steel, typically SS304 or SS316.

These materials provide additional corrosion resistance and durability for larger head shafts in washdown conditions. Stainless steel bushings enhance the gearbox's ability to handle various shaft sizes while maintaining hygiene standards.

Stainless Steel Gear Motors

We introduce a comprehensive line of stainless steel IEC food safety motors, fitted with stainless steel worm gear reducers, specifically designed for demanding washdown conditions in industries where sanitation is crucial. Our Food Safety series motors and worm gear motors are particularly well-suited for the meat, poultry, fish, and dairy industries, where the risk of severe contamination is high.

To minimize contamination risks and reduce the amount of water and chemicals required to sanitize equipment, all of our food safety products are designed for easy cleaning. The stainless steel motors feature smooth, rounded housings that eliminate gaps where food particles could get trapped and bacteria could grow. Even the nameplates on our motors and gears are laser-etched to prevent channels and ridges where contaminants might accumulate.

Our entire food-safe range is equipped with an advanced sealing system, achieving an IP69 waterproof rating, which is the standard for products used in sanitary sectors. This classification ensures that our products can withstand cleaning by high-pressure water jets, commonly used in cleaning-in-place (CIP) procedures. The all-stainless steel construction further protects against corrosion.

Our stainless steel safety motors and worm gear reducers also feature encapsulated windings, offering longer life in harsh washdown conditions compared to general-purpose products. Additionally, these motors eliminate the need for motor shrouds, which can trap food particles and encourage bacterial growth. They are available in power ranges from 0.18 to 7.5 kW, with 2-6 pole versions for 230-690 volts, and 50 or 60 Hz frequencies.

With our complete food safety offering, we are well-positioned to serve customers and equipment manufacturers in the global food industry, whether using metric or imperial measurements.

Choose Our Stainless Steel Worm Gear Reducers and Motors

- Smooth stainless steel casing allows for effortless cleaning and disinfection.

- IP69 waterproof certification ensures compatibility with in-place cleaning processes.

- Laser-etched nameplates prevent contamination often found under conventional nameplates.

- Encapsulated windings protect against water and moisture penetration.

- High efficiency and low surface temperatures contribute to reduced operational costs.

- Lubricated with H1 food-grade synthetic grease.

- Motors available in power ranges from 0.18 to 7.5 kW, with 2-6 poles, and voltage options of 230-690 V, supporting both 50 and 60 Hz frequencies.

Blogs Updated

What Are the Typical Operating Temperatures for Stainless Steel Worm Gearmotors?

Stainless steel worm gearmotors are widely used in various industries because of their durability and efficiency. However, to ensure their optimal performance, it is important to understand their typical operating temperatures. Read on to learn more about this topic....

Are There Different Mounting Options for Stainless Steel Worm Gearmotors?

Stainless steel worm gearmotors are widely used in various industries, including the food and beverage industry, chemical industry, and many more. One of the key factors that make them so popular is their versatility and the different mounting options they offer. In...

How to Ensure Smooth Start and Stop Operations with Stainless Steel Worm Gearmotors?

Stainless steel worm gearmotors are widely used in various industries, including the food industry, beverage industry, and pharmaceutical industry. They offer several benefits, such as corrosion resistance, durability, high load capacity, and low noise levels....