In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

Specifications

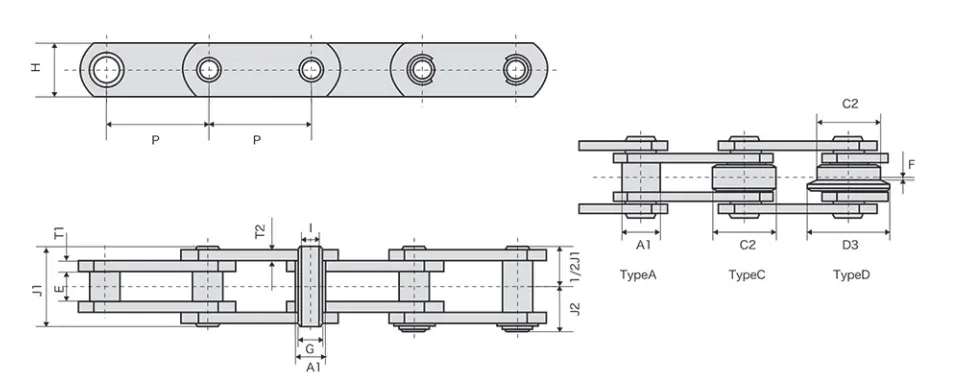

The ZC300SS ZC Series Stainless Steel Hollow Pin Chain features the following specifications:

- Material: Stainless Steel

- Type: Hollow Pin Chain

- Model: ZC300SS

| Chain No. |

Minimum Breaking Load,Ibf | Pitch Inches | Pitch(mm) | E | C2 | D3 | F | A1 | G | I | H | T1 | T2 | J1 | J2 | Breaking(load kN) | Mass (Type C) (kg/m) |

| ZC21SS | 4500 | 1.5 | 38.1 | 12.7 | 25.4 | 11 | 9 | 6.5 | 18 | 2.5 | 2.5 | 26 | 14.5 | 14.7 | 2.2 | ||

| ZC21SS | 4500 | 2 | 50.8 | 12.7 | 25.4 | / | 11 | 9 | 6.5 | 18 | 2.5 | 2.5 | 26 | 14.5 | 14.7 | 1.7 | |

| ZC21SS | 4500 | 2.5 | 63.5 | 12.7 | 25.4 | / | 11 | 9 | 6.5 | 18 | 2.5 | 2.5 | 26 | 14.5 | 14.7 | 1.6 | |

| ZC21SS | 4500 | 3 | 76.2 | 12.7 | 25.4 | / | / | 11 | 9 | 6.5 | 18 | 2.5 | 2.5 | 26 | 14.5 | 14.7 | 1.4 |

| ZC40SS | 6000 | 2 | 50.8 | 15 | 31.75 | 40 | 2.5 | 17 | 14 | 10.2 | 25 | 4 | 4 | 36.4 | 19.5 | 28 | 3.6 |

| ZC40SS | 6000 | 2.5 | 63.5 | 15 | 31.75 | 40 | 2.5 | 17 | 14 | 10.2 | 25 | 4 | 4 | 36.4 | 19.5 | 28 | 3.2 |

| ZC40SS | 6000 | 3 | 76.2 | 15 | 31.75 | 40 | 2.5 | 17 | 14 | 10.2 | 25 | 4 | 4 | 36.4 | 19.5 | 28 | 3 |

| ZC40SS | 6000 | 3.5 | 88.9 | 15 | 31.75 | 40 | 2.5 | 17 | 14 | 10.2 | 25 | 4 | 4 | 36.4 | 19.5 | 28 | 2.8 |

| 7C40SS | 6000 | 4 | 101.6 | 15 | 31.75 | 40 | 2.5 | 17 | 14 | 10.2 | 25 | 4 | 4 | 36.4 | 19.5 | 28 | 2.6 |

| ZC40SS | 6000 | 5 | 127 | 15 | 31.75 | 40 | 2.5 | 17 | 14 | 10.2 | 25 | 4 | 4 | 36.4 | 19.5 | 28 | 2.4 |

| ZC40SS | 6000 | 6 | 152.4 | 15 | 31.75 | 40 | 2.5 | 17 | 14 | 10.2 | 25 | 4 | 4 | 36.4 | 19.5 | 28 | 2.3 |

| ZC60SS | 12000 | 3 | 76.2 | 19 | 47.5 | 60 | 3.5 | 23 | 19 | 13.2 | 40 | 5 | 4 | 45 | 23.5 | 42 | 7 |

| ZC60SS | 12000 | 3.5 | 88.9 | 19 | 47.5 | 60 | 3.5 | 23 | 19 | 13.2 | 40 | 5 | 4 | 45 | 23.5 | 42 | 6.4 |

| ZC60SS | 12000 | 4 | 101.6 | 19 | 47.5 | 60 | 3.5 | 23 | 19 | 13.2 | 40 | 5 | 4 | 45 | 23.5 | 42 | 6 |

| ZC60SS | 12000 | 5 | 127 | 19 | 47.5 | 60 | 3.5 | 23 | 19 | 13.2 | 40 | 5 | 4 | 45 | 23.5 | 42 | 5.3 |

| ZC60SS | 12000 | 6 | 152.4 | 19 | 47.5 | 60 | 3.5 | 23 | 19 | 13.2 | 40 | 5 | 4 | 45 | 23.5 | 42 | 4.9 |

| ZC60SS | 12000 | 7 | 177.8 | 19 | 47.5 | 60 | 3.5 | 23 | 19 | 13.2 | 40 | 5 | 4 | 45 | 23.5 | 42 | 4.6 |

| ZC60SS | 12000 | 8 | 203.2 | 19 | 47.5 | 60 | 3.5 | 23 | 19 | 13.2 | 40 | 5 | 4 | 45 | 23.5 | 42 | 4.4 |

| ZC150SS | 24000 | 4 | 101.6 | 26 | 66.7 | 82 | 4 | 33 | 26.9 | 20.2 | 50 | 7 | 5 | 58 | 31.5 | 105 | 12.8 |

| ZC150SS | 24000 | 5 | 127 | 26 | 66.7 | 82 | 4 | 33 | 26.9 | 20.2 | 50 | 7 | 5 | 58 | 31.5 | 105 | 11.3 |

| ZC150SS | 24000 | 6 | 152.4 | 26 | 66.7 | 82 | 4 | 33 | 26.9 | 20.2 | 50 | 7 | 5 | 58 | 31.5 | 105 | 11 |

| ZC150SS | 24000 | 7 | 177.8 | 26 | 66.7 | 82 | 4 | 33 | 26.9 | 20.2 | 50 | 5 | 58 | 31.5 | 105 | 9.5 | |

| ZC150SS | 24000 | 8 | 203.2 | 26 | 66.7 | 82 | 4 | 33 | 26.9 | 20.2 | 50 | 7 | 5 | 58 | 31.5 | 105 | 9 |

| ZC150SS | 24000 | 9 | 228.6 | 26 | 66.7 | 82 | 4 | 33 | 26.9 | 20.2 | 50 | 7 | 5 | 58 | 31.5 | 105 | 8.6 |

| ZC150SS | 24000 | 10 | 254 | 26 | 66.7 | 82 | 4 | 33 | 26.9 | 20.2 | 50 | 7 | 5 | 58 | 31.5 | 105 | 8.2 |

| ZC300SS | 36000 | 6 | 152.4 | 38 | 88.9 | 114 | 8.5 | 38 | 32 | 22.5 | 60 | 10 | 8 | 83 | 43.5 | 210 | 22.3 |

| ZC300SS | 36000 | 7 | 177.8 | 38 | 88.9 | 114 | 8.5 | 38 |

Additional information

Blogs Updatedread more The Structure and Design Features of Sprockets in Scraper ConveyorsThis article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical... Scrapping and Replacement Standards for Chain Electric Hoist Lifting SprocketsThe scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the... |