Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

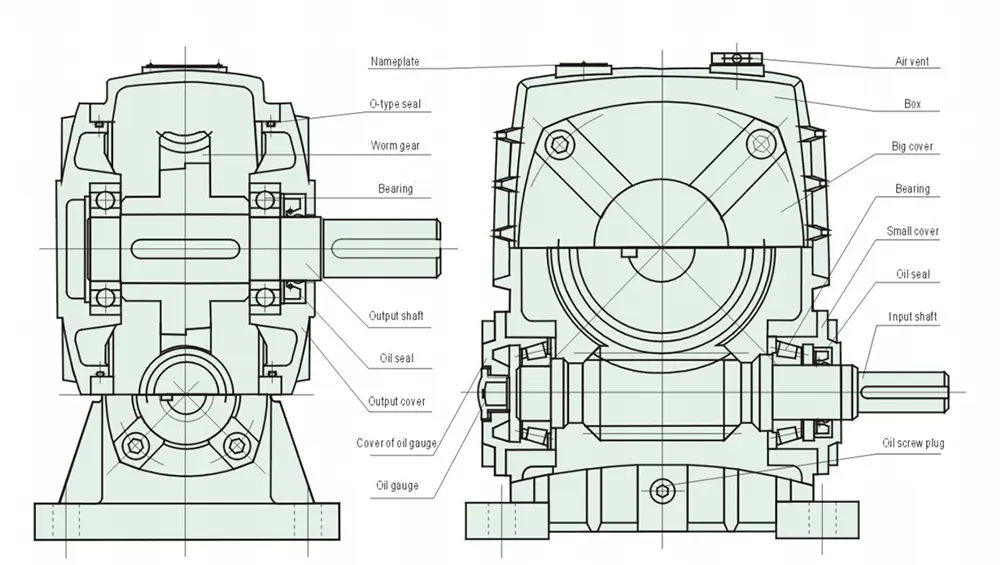

Product Overview - WPWDV Universal Speed Cast Iron Worm Gear Reducer

The WPWDV Universal Speed Cast Iron Worm Gear Reducer, also known as the WPWDV model, is a premier worm gear reducer that delivers exceptional performance and durability. It is ideal for a wide range of applications, including machinery, automation systems, and industrial equipment.

Key Features of WPWDV Universal Speed Cast Iron Worm Gear Reducer

- High-quality cast iron construction for enhanced strength and durability

- Precision-engineered worm gear design for efficient power transmission

- Smooth and quiet operation, ensuring minimal noise and vibration

- Wide range of available ratios to meet various speed requirements

- Compact and space-saving design for easy installation

- Excellent heat dissipation capabilities for extended service life

Technical Specifications

Below are the detailed technical specifications of the WPWDV Universal Speed Cast Iron Worm Gear Reducer:

Proper installation and usage of the WPWDV Universal Speed Cast Iron Worm Gear Reducer are crucial for optimal performance and longevity. Consider the following important factors: The WPWDV Universal Speed Cast Iron Worm Gear Reducer may encounter certain faults during operation. Here are some common issues and their respective causes and solutions: The WPWDV Universal Speed Cast Iron Worm Gear Reducer is often paired with electric motors to provide a comprehensive power transmission solution. The motor and reducer work synergistically to ensure efficient and reliable operation of machinery and equipment. At our company, we also offer a wide range of high-quality electric motors for sale to meet various customer needs. Ever-power is a leading transmission equipment manufacturer with over 20 years of experience in designing, producing, manufacturing, and selling speed reducers. We are known for our commitment to quality, innovation, and customer satisfaction. Our products, including the WPWDV Universal Speed Cast Iron Worm Gear Reducer, are highly regarded in the market. We serve a diverse range of customers globally, with a strong presence in Europe and America. At Ever-power, we pride ourselves on our state-of-the-art production facilities and talented team of professionals and technicians. We employ advanced production and testing equipment to ensure the highest standards of quality and performance. Our gearboxes are widely used in various industries, including equipment, food, car washing, packaging, transmission, automation, and solar energy. We are dedicated to providing our customers with the best products, superior service, and competitive prices. We encourage you to explore our WPWDV Universal Speed Cast Iron Worm Gear Reducer and contact us for purchasing inquiries. A: The maximum allowable operating temperature of the WPWDV Universal Speed Cast Iron Worm Gear Reducer is 95 degrees Celsius. It is essential to ensure that the oil temperature does not exceed this limit to maintain optimal performance and reliability. A: Yes, the WPWDV Universal Speed Cast Iron Worm Gear Reducer is designed to handle heavy-duty applications. Its high-quality cast iron construction and precision-engineered worm gear design ensure durability and efficient power transmission, making it suitable for demanding industrial environments. A: It is recommended to follow the manufacturer's guidelines for lubricating oil selection and replacement intervals. Generally, the initial oil change is recommended after 100 hours of operation, and subsequent oil changes should be performed regularly as specified by the manufacturer.

Possible Faults and Troubleshooting

Fault

Cause

Solution

Overheating

Lack of lubrication or excessive load

Ensure proper lubrication and reduce the load

Vibration

Imbalanced load or misalignment

Check load distribution and alignment, make necessary adjustments

Noise

Worn gears or inadequate lubrication

Inspect and replace worn gears, ensure proper lubrication

Oil leakage

Damaged seals or loose fittings

Replace damaged seals and tighten fittings

Motors for Worm Reducers

About Ever-power

Q&A

Q: What is the maximum operating temperature of the WPWDV Universal Speed Cast Iron Worm Gear Reducer?

Q: Can I use the WPWDV Universal Speed Cast Iron Worm Gear Reducer for heavy-duty applications?

Q: How often should I change the lubricating oil in the WPWDV Universal Speed Cast Iron Worm Gear Reducer?

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...