Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

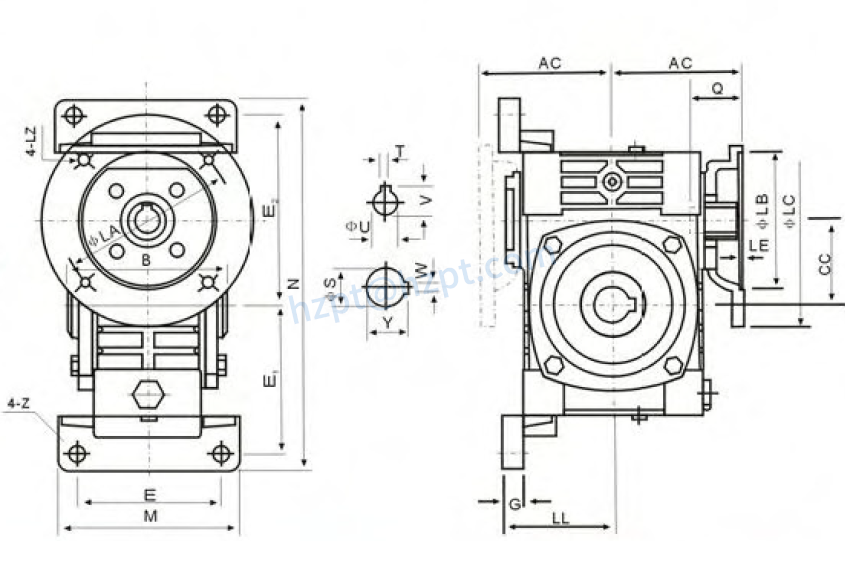

WPWDKT Series Universal Speed Worm Gearboxes

The WPWDKT series universal speed cast iron worm gear reducer is a high-performance product widely used in various industries such as the chemical industry, printing, packaging, lifting, food, and more. It is composed of essential components such as the worm gear, worm, bearing, and casing, along with other parts like oil seals, caps, and bolts. The worm gear is typically made of tin bronze, and the paired worm material is hardened to HRC4555 with 45 steel or 40Cr hardened to HRC5055, then ground to a roughness of Ra0.8??m by a worm grinder.

WPWDKT Worm Gearboxes

| Type | WPWDKT worm gearboxes |

| Model | WPWDKT 40-250 |

| Ratio | 1:10,15,20,25,30,40,50,60 |

| Color | Blue/Green Or On Customer Request |

| Material | Housing: Die-Cast Iron cast |

| Worm Gear-Copper-10-3# | |

| Worm-20CrMn Ti with carburizing and quenching, the surface hardness is 56-62HRC | |

| Shaft-chromium steel-45# | |

| Packing | Carton and Wooden Case |

| Bearing | C&U Bearing |

| Seal | KSK |

| Warranty | 1 Year |

| Input Power | 0.06KW,0.09KW |

| Usages | Industrial Machine: Food Stuff, Ceramics, Chemicals, Packing, Dyeing, Woodworking, Glass, AND SO ON |

| IEC Flange | 56B14, 63B14, 63B5, 63B5, 71B14,80B14 AND SO ON |

| Lubricant | Synthetic&Mineral |

Structural Features of Worm Gear Reducer:

- A large transmission ratio can be obtained, which is more compact than the staggered-axis helical gear mechanism.

- The meshing tooth surfaces of the two wheels are in line contact, and their bearing capacity is much higher than that of the staggered shaft helical gear mechanism.

- The worm drive is equivalent to a screw drive, a multi-tooth meshing drive, so the industry is stable, the noise is slight, and it is self-locking.

- When the lead angle of the worm is less than the equivalent friction angle between the meshing gear teeth, the mechanism has self-locking properties and can achieve reverse self-locking; that is, only the worm can drive the worm, but not the worm. Such as the self-locking worm mechanism used in its heavy machine, its reverse self-locking can play a role in safety protection.

- The transmission efficiency is low, and the wear is severe. When the worm gear is engaged in the transmission, the relative sliding speed between the meshing gear teeth is significant, so the friction loss is substantial, and the efficiency is low. On the other hand, the relative sliding speed causes severe wear and heat generation on the tooth surface. More expensive materials with good anti-friction and anti-wear properties and suitable lubricating devices are often used to dissipate heat and reduce wear, so the cost is high.

- The axial force of the worm is large.

Packing and Transportation

To ensure the integrity of product appearance, we will choose cartons, wooden pallets, and wooden pallets according to customer needs. Each reducer is manufactured and tested by strict and fixed procedures to ensure that the quality is correct before leaving the factory and delivery on time. We will choose the most suitable mode of transportation for our customers according to the weight and size of the goods, and we can also choose the mode of transportation according to our customers' needs. After receiving the goods, please check whether they are in good condition. We will provide customers with perfect after-sales service.

About Us

Ever-power is a comprehensive transmission equipment manufacturer integrating research and development, manufacturing, and sales of speed reducers. With over 25 years of experience in the design, production, manufacture, and sales of gearboxes, we serve customers in Europe, America, Africa, Asia, and more. We have introduced advanced production equipment and testing equipment at home and abroad, employing industry professionals and technicians to carry out innovative research and development and manufacturing. The use of standardized production management methods strictly controls every aspect of the production of reducers. Over the years, we have provided customers with high-quality, high-energy-efficiency, high-stability production of crystals. Our gearboxes are widely used in equipment Industry, food industry, car washing industry, packaging industry, transmission industry, automation industry, solar energy industry, and so on. We welcome and are trusted by customers.

Electric Motors for Sale

Electric motors are an essential component when it comes to the operation of the WPWDKT series universal speed worm gearboxes. They are responsible for converting electrical energy into mechanical energy, which is then used to power the gearboxes and drive machinery. We offer a range of electric motors for sale that are compatible with our gearboxes and can provide high-quality, efficient performance.

FAQ

A: You can refer to our catalog to choose the gearbox, or we can help to decide when you provide the technical information of required output torque, speed, and motor parameters.

A:

- Type of the gearbox, ratio, input and output type, input flange, mounting position, and motor information.

- Housing color.

- Purchase quantity.

- Other special requirements.

A: Our gearboxes are widely used in various industries, including textile, food processing, beverage, chemical industry, escalator, automatic storage equipment, metallurgy, tobacco, environmental protection, logistics, and more.

A: Yes, we offer a range of electric motors for sale that are compatible with our gearboxes and can provide high-quality, efficient performance.

A: We provide customers with perfect after-sales service. If there are any problems with our products, we will solve them in a timely and efficient manner to ensure customer satisfaction.

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...