Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

WPKZ Single Stage Cast Iron Worm Reducer

The WPKZ Single Stage Cast Iron Worm Reducer is a high-quality gearbox designed for various mechanical equipment. It consists of transmission parts, worm gear, shaft, bearing, box, and accessories. The gearbox can be divided into three essential structural parts: the box, worm gear, and worm, bearing, and shaft combination. The box serves as the base for all the accessories in the worm gear reducer, providing support and fixing the shafting parts, maintaining the correct relative position of the transmission accessories, and carrying the load acting on the reducer. The worm gear is primarily responsible for transferring motion and power between two staggered shafts, while bearings and shafts share control and operation to improve efficiency.

|

|

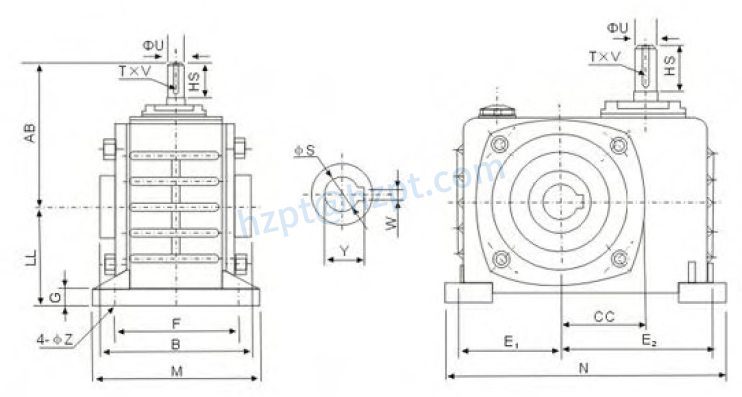

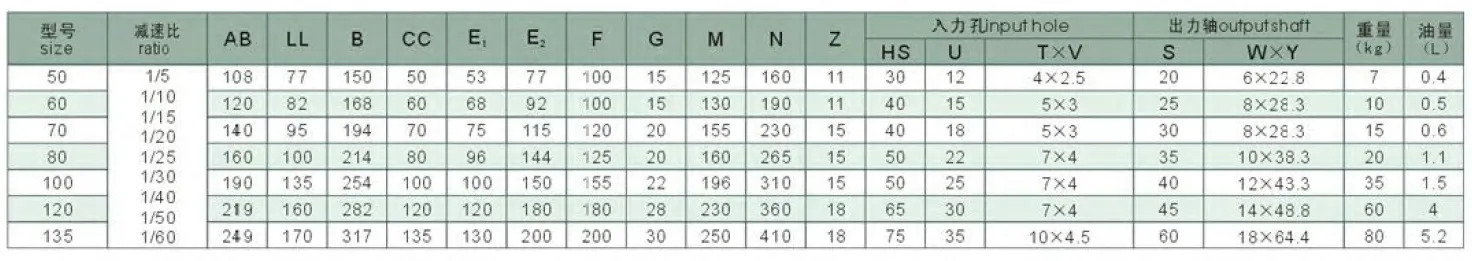

Product Specifications

WPKZ Single Stage Cast Iron Worm Reducer Features:

- Smooth and vibration-free operation

- Negligible impact and noise

- Large deceleration ratio

- Wide versatility, compatible with various mechanical equipment

- Single-stage transmission for obtaining large transmission ratio

- Compact structure with better self-locking performance

- Reduced need for braking devices in equipment with braking requirements

- Lower

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...