Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

WPKA Series Worm Gearboxes: High-Quality Steel Products

WPKA series worm gearboxes are made of high-quality steel through heat treatment, ensuring maximum durability and wear resistance. The worm wheel is made of tin bronze, providing excellent bearing capacity. These gearboxes are widely used in various industries, including plastics, metallurgy, beverage, mining, lifting and transportation, chemical industry, and construction.

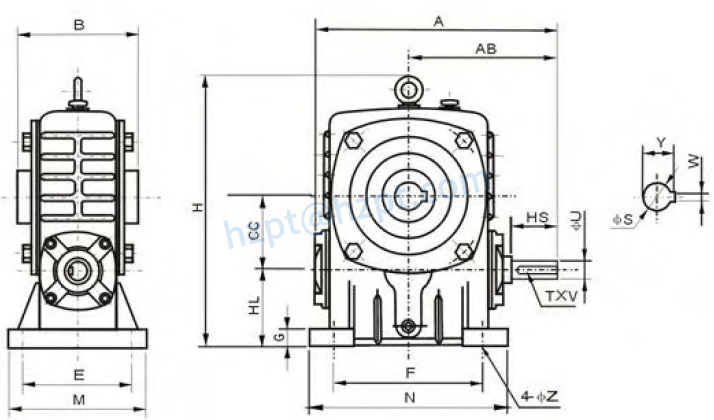

Product Specifications

The WP series products come in 60 series with more than 20,000 different specifications, transmission ratios between 10-900, input power ranging from 0.12-33.2 kW, and output torque from 6-6050N.m. They offer stable transmission, large carrying capacity, low noise, compact structure, and significant reduction ratio. Different connection and installation methods are also available to meet various user needs.

|

|

Characteristics of Cast Iron Worm Gearbox

1. The worm gear reducer offers stable transmission, low vibration, impact, and noise. It has a large reduction ratio and wide universality and can be used with various mechanical equipment.

2. The meshing friction loss between the worm tooth and worm gear tooth surface is significant, and the transmission efficiency is lower than gear, easy to heat and high temperature.

3. Higher requirements for lubrication and cooling.

4. It can obtain a large transmission ratio with single-stage transmission and compact structure. Most reducers have good self-locking and can save braking devices for mechanical equipment requiring braking.

5. The box type includes the primary type (the box body is a vertical or horizontal structure with baseboard) and universal type (the box body is rectangular, with fixed screw holes on many sides, without baseboard or with baseboard).

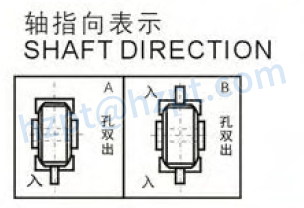

6. There are two connection modes of the input shaft of cast iron worm gear reducer: primary type (single input shaft and double input shaft) and with motor flange.

7. The position direction of the output and input shaft has the input shaft down and up; Output axial up and down; Input axial up and down.

8. Good compatibility, worm gears, and worms are manufactured according to national standards, and standard parts are used for bearings and oil seals.

9. Two or three reducers can form a multi-stage reducer to obtain an excellent transmission ratio.

|

|

|

Packing and Transportation

??Packaging: We offer cartons, wooden pallets, and wooden pallets according to customer needs to ensure the integrity of product appearance.

??Delivery time: Each gearbox undergoes strict and fixed procedures to ensure the correct quality before leaving the factory, ensuring timely delivery.

??Transportation mode: We will choose the most suitable mode of transportation for our customers, depending on the weight and size of the goods and our customer's needs.

??Receiving and after-sales service: After receiving the goods, please check whether they are in good condition. We will provide customers with perfect after-sales service.

Why Choose Our Worm Gearbox?

At Ever-power, we handle power transmission products. Our lines mainly cover series products in speed reducers, gearboxes, electric motors, and other power transmission accessories. Our products can be utilized in many fields, including wastewater treatment machines, dredgers, the chemical industry, cranes, metalworking mills, conveyors, the paper industry, the cement industry, cableways, and more.

Our consistent mission and vision over the years have been to provide customers with high-quality products that are energy-efficient, stable, and meet their unique needs. We have introduced advanced production and testing equipment, employing industry professionals and technicians to carry out innovative research and development and manufacturing. The use of standardized production management methods allows us to strictly control every aspect of the production of reducers, ensuring maximum quality and reliability.

We have more than 25 years of experience in the design, production, manufacture, and sales of gearboxes, serving customers in Europe, America, Africa, Asia, and other regions. Our products enjoy a good reputation from customers and peers worldwide.

Electric Motors for Sale

Our gearboxes are designed to work seamlessly with our electric motors. We offer a wide range of electric motors for sale, ensuring maximum compatibility, reliability, and efficiency. The right motor can help you get the most out of your gearbox, ensuring maximum performance and longevity.

About Us

Ever-power is a comprehensive transmission equipment manufacturer integrating research and development, manufacturing, and sales of speed reducers. Our products are used in various industries, including the equipment industry, food industry, car washing industry, packaging industry, transmission industry, automation industry, solar energy industry, and many more.

We are dedicated to providing our customers with the highest quality products and services at competitive prices. We have won the trust and loyalty of our customers through our commitment to excellence, innovation, and customer satisfaction. Our main clients are located in Europe and the United States, and we are proud to have earned their trust and respect.

Q&A

Q: What is the maximum transmission ratio of the WP series worm gearbox?

A: The WP series worm gearbox can achieve a maximum transmission ratio of 900.

Q: What is the input power range of the WP series worm gearbox?

A: The input power range of the WP series worm gearbox is 0.12-33.2 kW.

Q: What industries are the WPKA series worm gearboxes widely used in?

A: The WPKA series worm gearboxes are widely used in plastics, metallurgy, beverage, mining, lifting and transportation, chemical industry, and construction.

Q: What are the characteristics of the cast iron worm gearbox?

A: The cast iron worm gearbox offers stable transmission, low vibration, impact, and noise. It has a large reduction ratio and wide universality and can be used with various mechanical equipment. The meshing friction loss between the worm tooth and worm gear tooth surface is significant, and the transmission efficiency is lower than gear, easy to heat and high temperature, requiring higher lubrication and cooling. It can obtain a large transmission ratio with single-stage transmission and compact structure. Most reducers have good self-locking and can save braking devices for mechanical equipment requiring braking.

Q: What is the advantage of using Ever-power's electric motors with their gearboxes?

A: Our electric motors are designed to work seamlessly with our gearboxes, ensuring maximum compatibility, reliability, and efficiency. The right motor can help you get the most out of your gearbox, ensuring maximum performance and longevity.

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...