Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

Introducing the WPEDS Series Double Stage Cast Iron Worm Gearbox

WPEDS Series Double Stage Worm Gearboxes

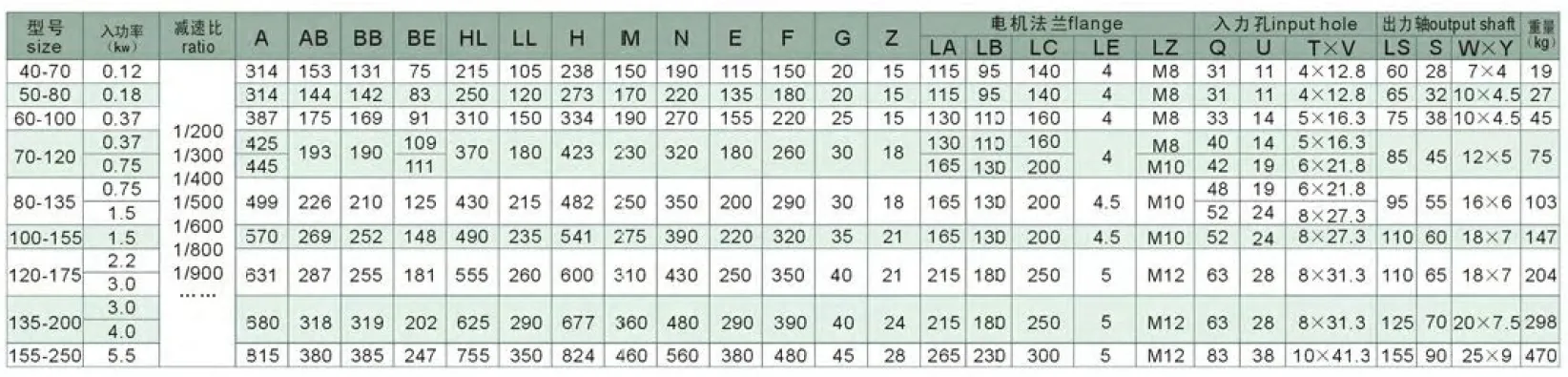

The WPEDS Series Double Stage Cast Iron Worm Gearbox is a high-quality product designed for industrial applications. Its material combination of the worm and worm gear ensures excellent wear resistance and running-in performance. The worm is made of alloy steel or high-quality carbon steel, with a carburized, quenched, or nitrided surface to achieve high hardness. The hardness of the worm gear ring, which is made of tin bronze, is generally between 35-55HRC. The gearbox is available in various ratios, including 1:200, 300, 400, 500, 600, 800, and 900.

This double stage worm gearbox is designed for durability and efficiency. Its housing is made of die-cast iron cast, providing robustness and stability. The worm gear is made of copper-9-4#, and the worm itself is made of 20CrMn Ti with carburizing and quenching, resulting in a surface hardness of 56-62HRC. The shaft is made of chromium steel-45#, ensuring strength and reliability.

The WPEDS Series Worm Gearbox is widely used in various industrial machines, including those in the food stuff, ceramics, chemical, packing, dyeing, woodworking, glass, and other industries. It comes with different IEC flange options, such as 56B14, 63B14, 63B5, 71B14, and 80B14. The gearbox uses synthetic and mineral lubricants to ensure smooth operation.

The WPEDS Series Double Stage Worm Gearbox is packed in cartons and wooden cases to ensure safe transportation. It comes with a one-year warranty, providing peace of mind to the customers. Its excellent performance and reliable quality make it an ideal choice for industrial applications.

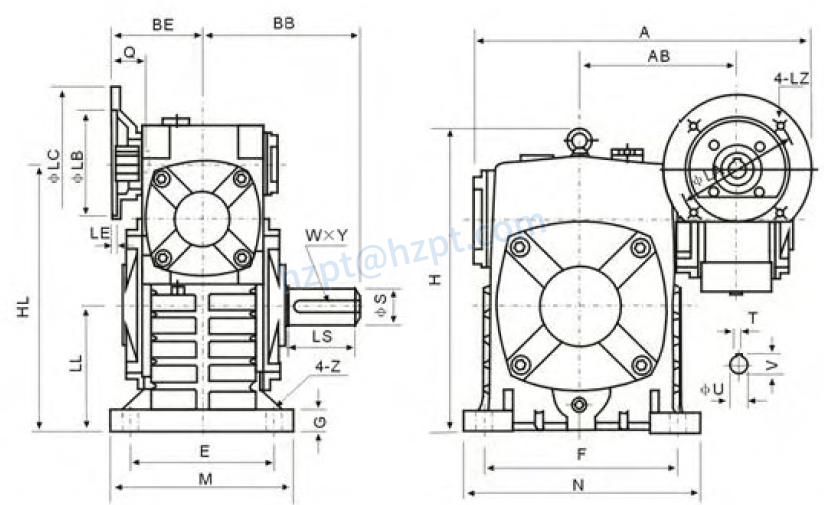

Product Specifications

Inspection Work Before Using Worm Gearboxes

Before using the worm gearbox, it is important to check the weight, type, power, speed ratio, and shaft direction of the gearbox. Additionally, ensure that the oil level inside the gearbox is above half the meter. The installation site should be well-ventilated with a temperature range of 0-40 degrees Celsius. When connecting with couplings, make sure the two shafts are equal and aligned, and securely fix the mounting feet of the worm gearbox.

Packing and Transportation

For packaging, we offer cartons, wooden pallets, and wooden pallets according to the customer's needs to ensure the integrity of the product appearance. Each gearbox undergoes strict and fixed procedures for manufacturing and testing to ensure quality and timely delivery. We choose the most suitable transportation mode based on the weight and size of the goods. After receiving the goods, please check their condition, and we will provide perfect after-sales service.

Electric Motors for Sale

The WPEDS Series Double Stage Worm Gearbox is the perfect companion for

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...