Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

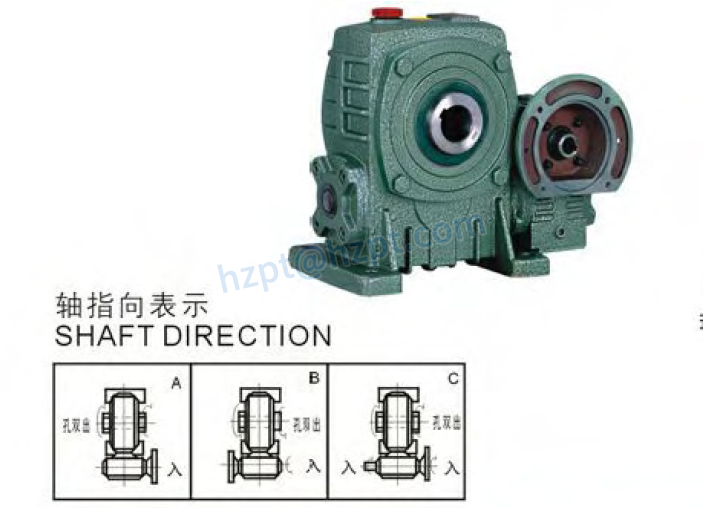

WPEDKA Series Double Stage Worm Gearboxes

At Ever-power, we are proud to introduce our WPEDKA Series Double Stage Worm Gearboxes. These gearboxes are widely used in various industries due to their beautiful appearance, easy installation, and high torque capabilities. Whether it's in ships, automobiles, heavy machinery, or even household appliances, our gearboxes can be found in a wide range of applications.

Our worm gearboxes serve the important function of deceleration and torque increase in industrial applications, making them an essential component in speed and torque conversion equipment.

|

|

WPEDKA Worm Drive Gearbox

| Type | worm drive gearbox |

| Model | WPEDKA |

| Ratio | 1: 200, 300, 400, 500, 600, 800, 900 |

| Color | Blue/Green Or On Customer Request |

| Material | Housing: Die-Cast Iron cast |

| Worm Gear-Copper-10-3# | |

| Worm-20CrMn Ti with carburizing and quenching, the surface hardness is 56-62HRC. | |

| Shaft-chromium steel-45# | |

| Packing | Carton and Wooden Case |

| Warranty | 1 Year |

| Usages | Industrial Machine: Food Stuff, Ceramics, Chemicals, Packing, Dyeing, Woodworking, Glass. |

| IEC Flange | 56B14, 63B14, 63B5, 63B5, 71B14,80B14 AND SO ON |

| Lubricant | Synthetic&Mineral |

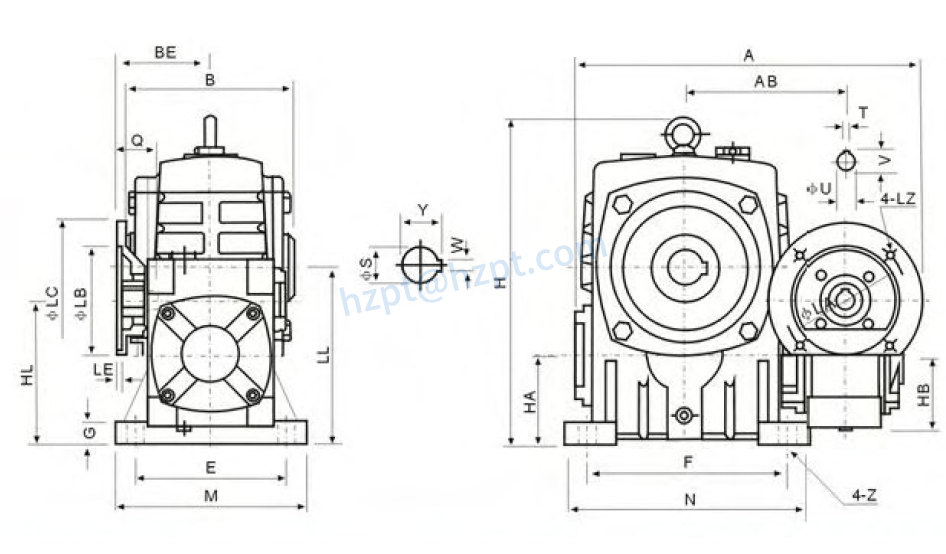

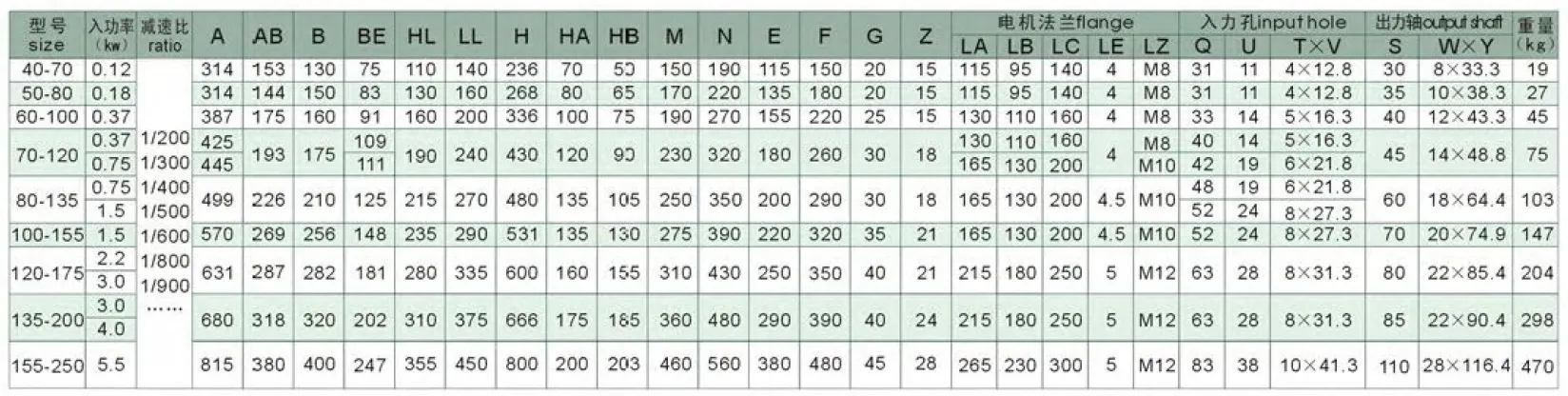

Specifications Parameter

Materials and Functions of Some Accessories of Worm Gearbox:

Housing: Aluminum alloy (seat:025-090) cast iron (seat:110-250);

Worm: 20Cr steel.Carbon and nitrogen co-treatment (after fine grinding, HRC60 hardness of tooth surface is maintained, hardness thickness is greater than 0.5mm);

Worm gear: specially equipped wear-resistant nickel bronze;

Oil cover/ventilator: mainly used to discharge the gas in

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...