Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

WPEDA Series Double Stage Cast Iron Worm Gearbox

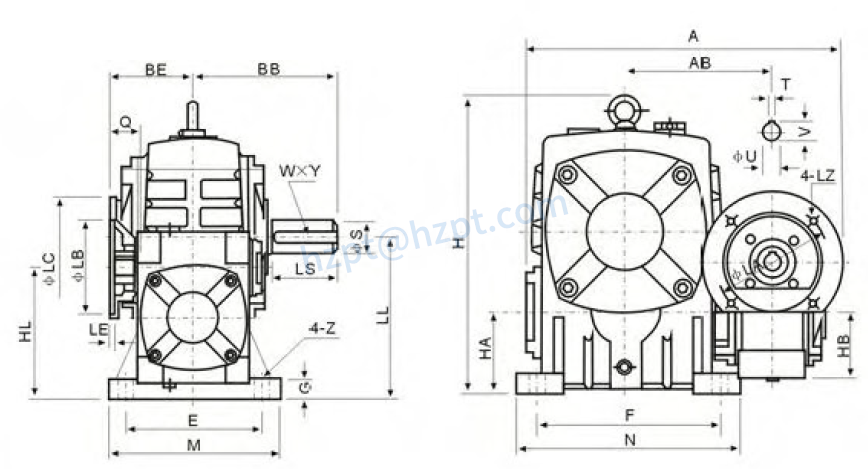

Worm gearboxes are widely used due to their durability, large transmission ratio, small size, strong self-locking ability, simple structure, and easy manufacturing, but their relatively low transmission efficiency. To add a breather cover to the worm gear reducer, the temperature of the reducer will change with the working time. The higher the temperature, the air in the reducer case will expand, thereby leaking the lubricating oil from the split surface, so a vent cover is provided on the reducer case cover. An oil drain hole is provided under the reducer case seat to facilitate the later replacement of lubricating oil.

|

|

Products Description

| Type | WPEDA worm gearbox |

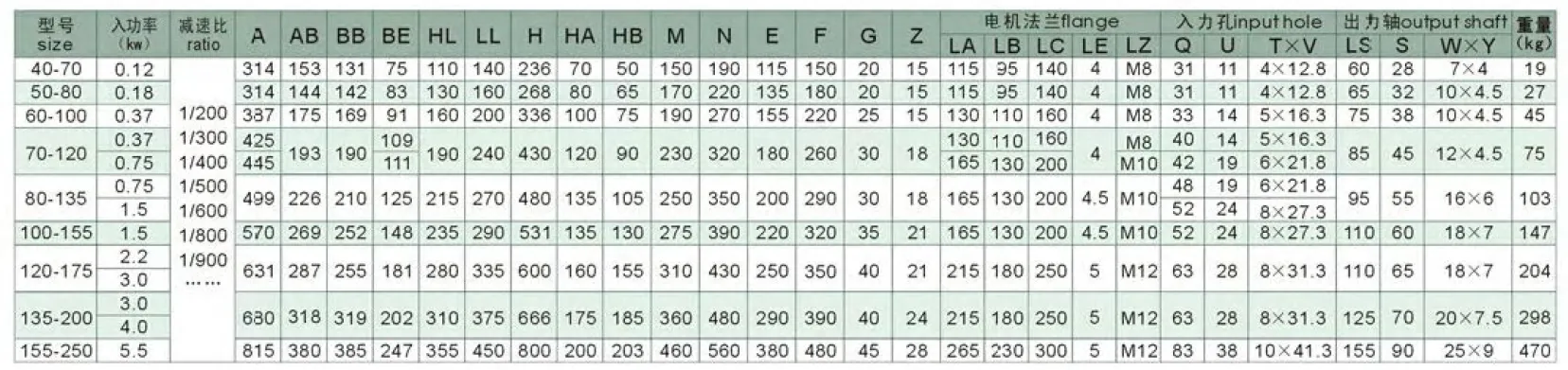

| Model | 40-70, 50-80, 60-100, 70-120, 80-147, 100-155, 120-175, 135-200, 155-250 |

| Ratio | 200-900 |

| Mounting Position | Foot mounted, flange mounted |

| Output Form | Solid shaft, hollow shaft |

| Material of Housing | Casting Iron |

| Material of Shaft | Chromium steel |

| Oil seal | KSK |

| Bearing | C&U |

Product Specifications

Features of WPEDA Series Worm Gearboxes

1. Widely transmission rate, large output torque

2. Structure: base-mounted, input flange, input shaft, additional single or double output shafts

3. Compact mechanical structure, small volume, light weight,

4. Having good temperature resistance

5. Easy mounting, free linking, high efficiency

6. Wide range of application

7. Smooth operation with lower noise or vibration

|

|

Packing and Transportation

??Packaging: To ensure the integrity of product appearance, we will choose cartons, wooden pallets, and wooden pallets according to customer needs.

??Delivery time: Each reducer is manufactured and tested by strict and fixed procedures to ensure that the quality is correct before leaving the factory and delivery on time.

??Transportation mode: We will choose the most suitable mode of transportation for our customers according to the weight and size of the goods. We can also choose the mode of transportation according to the needs of our customers.

??Receiving

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...