Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

WPDS Single Stage Cast Iron Worm Reducer: A Powerhouse of Efficiency and Reliability

The WPDS Single Stage Cast Iron Worm Reducer is a top-of-the-line product engineered to deliver exceptional performance and durability. With its advanced design and high-quality materials, this worm gearbox assembly offers unmatched efficiency in various industries, including food machines, conveyor equipment, industrial machines, foodstuff, ceramics, chemicals, packing, dyeing, woodworking, and glass.

|

|

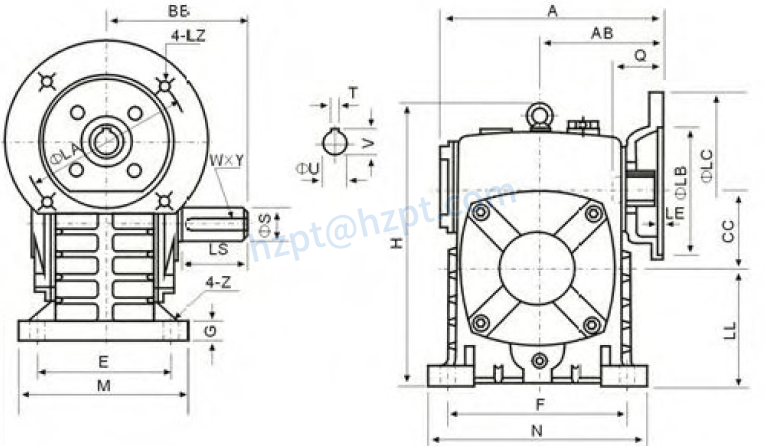

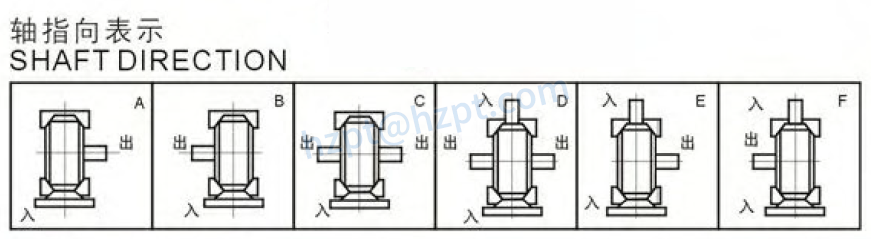

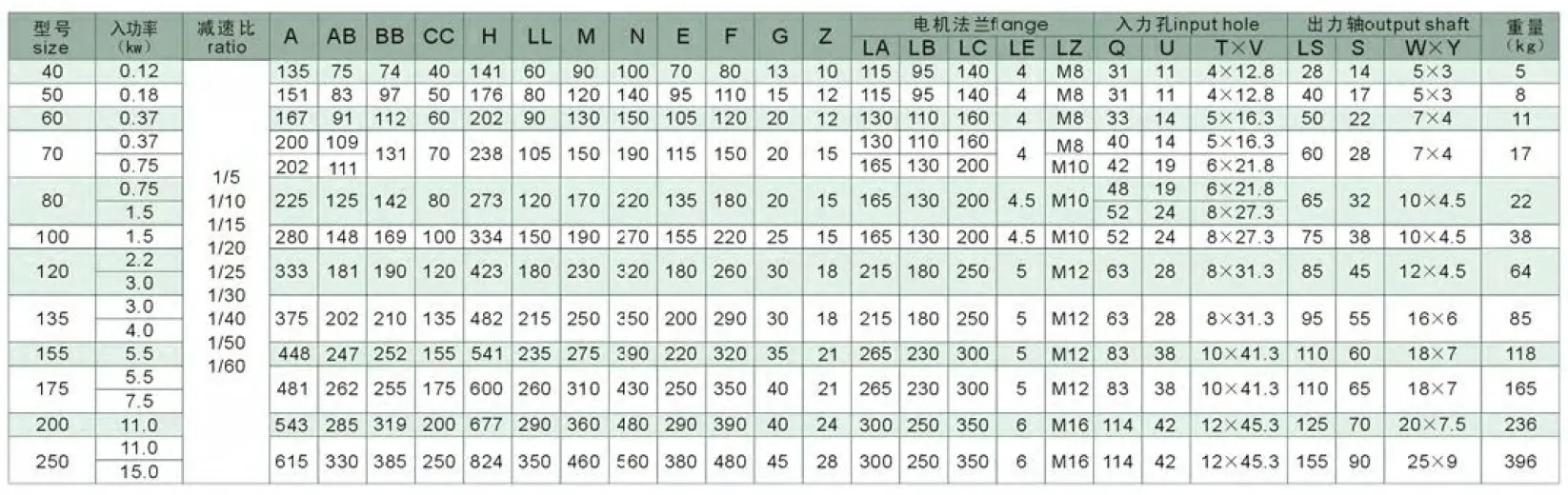

Product Specifications

High-Quality Output Shaft

The WPDS Single Stage Cast Iron Worm Reducer boasts a new standard axle that undergoes multi-precision machining. It has successfully passed rigorous dynamic and static balance tests, ensuring minimal noise and smooth operation for the reducer.

Precision Worm Gear

Crafted from 20CrMn Ti, a low carbon alloy steel, the precision worm gear undergoes meticulous processing using imported gear grinding machines. This results in a high hardness and stable performance. Additionally, the gear undergoes vacuum furnace carburizing heat treatment, which guarantees a uniform carburizing layer.

High-Quality Shell Material

The WPDS Single Stage Cast Iron Worm Reducer features a box body made of HT200 material. Each box body is meticulously cleaned using professional screening and washing equipment to ensure a cleaner inner cavity, free from any iron filings.

|

|

Application Area:

The WPDS Single Stage Cast Iron Worm Reducer is widely used in a diverse range of industries. Its versatility makes it an ideal choice for food machines, conveyor equipment, industrial machines, foodstuff, ceramics, chemicals, packing, dyeing, woodworking, and glass industries.

|

|

|

Packing and Transportation

?? Packaging: To ensure the product's integrity, we offer various packaging options such as cartons, wooden pallets, or custom packaging based on customer requirements.

?? Delivery time: Each WPDS Single Stage Cast Iron Worm Reducer undergoes strict manufacturing and testing procedures to ensure its quality before leaving the factory. This ensures timely delivery to our customers.

?? Transportation mode: We choose the most suitable transportation mode based on the weight and size of the goods. Our priority is to ensure safe and efficient delivery tailored to our customers' needs.

?? Receiving and after-sales service: Upon receiving the goods, please inspect them for any damage. We are committed to providing excellent after-sales service and addressing any concerns or inquiries our customers may have.

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...