Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

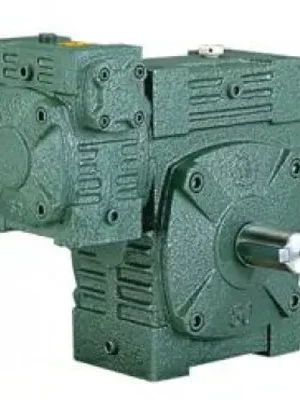

WPDKZ Single Stage Cast Iron Worm Reducer: A Versatile Solution for Mechanical Equipment

Are you looking for a reliable and efficient worm gearbox for your mechanical equipment? Look no further than the WPDKZ Single Stage Cast Iron Worm Reducer. With its smooth transmission, low vibration, and compact structure, this gearbox offers a wide range of benefits for various applications.

One of the key advantages of the WPDKZ series worm gearbox is its large reduction ratio, which allows for a greater transmission ratio in a single stage. This not only saves space but also improves the self-locking properties of the reducer. In fact, for mechanical equipment with braking requirements, the braking device can be omitted.

It is crucial for the WPDKZ series worm gearbox to have sufficient rigidity to avoid deformation after loading, ensuring optimal transmission quality and performance. With its durable construction and high-quality materials, this gearbox can withstand heavy loads and deliver reliable performance.

Product Specifications

Common Faults and Causes of Worm Gearboxes

To ensure the optimal performance of your worm gearbox, it is essential to be aware of common faults and their causes. Here are some potential issues you may encounter:

- The reducer heats up and leaks oil: This can occur due to the sliding friction transmission, generating excess heat and causing gaps in the mating surfaces. To prevent this, ensure proper material matching, high-quality friction surfaces, correct lubricating oil amount, and a suitable assembly environment.

- The worm gear wears out quickly: The worm gear is typically made of tin bronze, and wear may indicate incorrect selection, overloading, poor assembly quality, or unfavorable operating conditions.

- Wear of the transmission of small helical gear: This problem is more likely to occur in vertically installed reducers due to inadequate lubrication. Insufficient lubricating oil can lead to mechanical wear and damage during startup and improper lubrication and protection when the reducer stops running.

- Damage to the worm bearing: Even with good sealing, the gearbox may experience emulsified gear oil, rusted bearings, and corrosion. This is often caused by condensed water mixing with the gear oil due to temperature fluctuations.

|

|

Packing and Transportation

To ensure the integrity of the product appearance

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...