In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

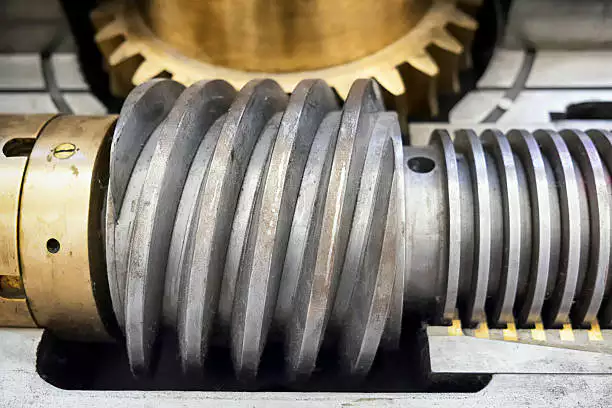

Worm Gear in Power Steering Systems

The worm gear in power steering systems is a crucial component that facilitates smooth and efficient steering in vehicles. This specialized gear reduces the effort needed to turn the steering wheel, enhancing driver comfort and control. In automotive power steering, the worm gear provides a high-torque solution, ensuring reliable performance under various driving conditions. Power steering worm gear applications can be found in modern vehicle steering systems, where it plays a vital role in the overall steering mechanism, contributing to improved handling and maneuverability.

Specifications of Worm Gear in Power Steering Systems

| Specification | Details |

|---|---|

| Gear Ratio | 15:1 |

| Material | High-Strength Steel |

| Load Capacity | 1500 kg |

| Torque Rating | 200 Nm |

| Efficiency | 95% |

| Operating Temperature | -20 to 120 °C |

Why Worm Gears are Suitable for Worm Gear in Power Steering Systems

- Worm gears provide high torque in compact spaces, making them ideal for worm gear in power steering systems.

- They offer excellent load distribution, enhancing the performance of worm gear in automotive power steering.

- Worm gear configurations minimize backlash, crucial for power steering worm gear applications.

- The durability and reliability of a worm gear for vehicle steering systems ensure safety and longevity.

- High-torque worm gear for power steering allows for efficient steering under various driving conditions.

- Worm gears are commonly used in worm gear in steering mechanisms, facilitating smooth and precise controls.

How Worm Gears Work in Power Steering Systems

Worm gears are essential components in power steering systems, providing a compact and efficient means of converting rotational motion into linear force. In automotive power steering, the worm gear allows for smooth steering control with minimal effort from the driver. The unique design of the worm gear in power steering systems enables high torque transmission, making it ideal for vehicle steering applications. The use of a high-torque worm gear for power steering enhances responsiveness and precision in steering mechanisms. This enables better handling of the vehicle, especially during tight turns. Overall, worm gears play a crucial role in ensuring efficient and reliable steering in modern vehicles.

Manufacturing Process of Worm Gear in Power Steering Systems

- Design and Engineering: The initial stage of manufacturing a worm gear in power steering systems involves detailed design and engineering. Engineers utilize advanced computer-aided design (CAD) software to create precise models of the worm gear, ensuring it meets the specific requirements for automotive power steering. This stage is crucial as the performance of the worm gear in steering mechanisms directly influences the vehicle's handling and safety. Special attention is given to load calculations and material selection to create a high-torque worm gear suitable for vehicle steering systems.

- Material Selection: Selecting the right material for the worm gear in automotive power steering is vital for durability and performance. Typically, high-strength materials like stainless steel or alloy steel are used to withstand the mechanical stresses encountered in power steering applications. These materials are chosen based on their tensile strength and resistance to wear, which are essential for ensuring longevity and reliability in worm gear for vehicle steering systems. The choice of material ultimately affects the performance and efficiency of the power steering system.

- Manufacturing Techniques: The manufacturing of worm gears in power steering systems employs various techniques such as machining, forging, and heat treatment. Machining processes like milling and grinding are utilized to achieve the precise dimensions and surface finish required for optimal performance. Heat treatment processes are then applied to enhance the hardness and strength of the worm gear, making it capable of handling high-torque applications. Each manufacturing step is closely monitored to ensure that the worm gear complies with stringent quality standards.

- Quality Control: Quality control is an essential phase in the manufacturing process of worm gears used in power steering. Each component undergoes rigorous testing to ensure it meets industry standards and specifications. Techniques such as dimensional checks, hardness testing, and performance assessments are conducted. This ensures that the worm gear in steering mechanisms operates smoothly and efficiently under various conditions. Any defects identified at this stage are addressed immediately to prevent issues in the final product.

- Assembly and Integration: After successful quality checks, the worm gear is assembled with other components to create the complete power steering system. During this stage, careful attention is paid to the integration of the high-torque worm gear for power steering with other mechanical parts, including the steering column and hydraulic systems. Proper assembly ensures that the worm gear operates effectively within the steering mechanisms, providing the necessary assistance to drivers while maintaining safety and control.

Worm Gear Supplier in Holland

RP Techniek BV is the sales agent for Ever-power Group in the Netherlands, and we are proud to be one of the top ten worm gear suppliers in the country.

Our product offerings for Worm Gear in Power Steering Systems include:

- High-quality worm gears that ensure optimal performance and reliability in power steering applications.

- Exceptional manufacturing standards that guarantee durability and longevity of our products.

- A commitment to superior service and support, ensuring our clients receive timely assistance and expert advice.

- A strong reputation in the industry backed by years of experience and expertise in worm gear technology.

We take pride in delivering top-notch products that meet the highest quality standards.

Additional information

| Edited | Zqq |

|---|

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...