In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

Worm Gear for Aircraft Control Surfaces

The worm gear for aircraft control surfaces is a crucial component used in aviation to ensure precise movement and control of flight surfaces. This specialized worm gear in aircraft control systems allows for smooth and efficient adjustments, enhancing aircraft maneuverability. With applications in various aircraft worm gear applications, it plays a vital role in achieving high precision and reliability. The high-precision worm gear for aircraft ensures that the worm gear for flight control surfaces operates effectively within worm gear in aerospace control mechanisms, contributing to overall flight safety and performance.

Specifications of Worm Gear for Aircraft Control Surfaces

| Specification | Details |

|---|---|

| Gear Ratio | 5:1 |

| Material | Aluminum Alloy |

| Load Capacity | 500 lbs |

| Efficiency | 85% |

| Temperature Range | -40°F to 250°F |

| Lubrication Type | Grease |

Why Worm Gears are Suitable for Worm Gear for Aircraft Control Surfaces

- Worm gears for aircraft control surfaces provide high precision, essential for maintaining stability and control during flight.

- The unique design of the worm gear in aircraft control systems minimizes backlash, ensuring smooth operation of flight control surfaces.

- Aircraft worm gear applications are ideal for managing the complex movements required in aerospace control mechanisms.

- High-precision worm gear for aircraft enhances reliability and performance, vital for aviation safety.

- Worm gear in aerospace control mechanisms allows for compact designs, saving space within aircraft structures.

How Worm Gears Work in Aircraft Control Surfaces

Worm gears play a critical role in aircraft control surfaces, providing precise motion and control in various flight applications. A worm gear for aircraft control surfaces converts rotational motion into linear movement, enabling the adjustment of flaps, ailerons, and rudders. This mechanism operates efficiently within aircraft worm gear applications, where its compact design and high torque output are essential. The worm gear in aircraft control systems ensures smooth and reliable operation, vital for flight safety. High-precision worm gears for aircraft are designed to withstand demanding aerospace conditions, making them ideal for aerospace control mechanisms. Their unique design minimizes backlash, enhancing control accuracy during flight maneuvers.

Manufacturing Process of Worm Gear for Aircraft Control Surfaces

- Material Selection: The manufacturing of worm gear for aircraft control surfaces begins with the selection of high-quality materials. Typically, materials such as alloy steel or aerospace-grade aluminum are chosen due to their strength and lightweight properties. These materials ensure that the worm gear in aircraft control systems can endure the high-stress conditions faced during operation. The chosen material should also have resistance to corrosion and wear, crucial for maintaining the integrity of flight control surfaces over time.

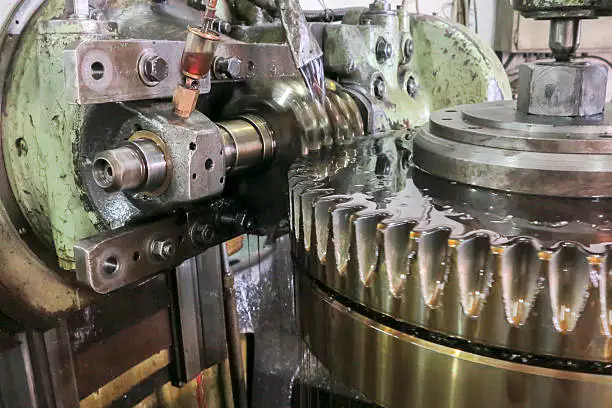

- Precision Machining: Once the material is selected, the next step in creating a high-precision worm gear for aircraft involves precision machining processes. Utilizing CNC (Computer Numerical Control) technology, the raw materials are shaped into the specific geometries required for the worm gear. This process is critical as it ensures that the worm gear for flight control surfaces meets the exact specifications needed for seamless integration into aerospace control mechanisms. The precision of the machining process contributes significantly to the overall performance and reliability of the aircraft's control surfaces.

- Heat Treatment: After machining, the worm gear undergoes heat treatment to improve its mechanical properties. This process not only enhances the hardness of the worm gear in aerospace control mechanisms but also increases its fatigue resistance. Heat treatment is essential in ensuring that the worm gear can withstand the dynamic loads experienced during flight operations. Properly treated worm gears extend their lifespan and maintain operational reliability, which is vital for the safety of aircraft control systems.

- Surface Finishing: The surface finishing stage is crucial for the performance of the worm gear. This process typically involves grinding and polishing to achieve a smooth finish, which reduces friction when the worm gear for aircraft control surfaces engages with its corresponding wheel. A smooth surface also contributes to the overall efficiency of the aircraft worm gear applications, allowing for better performance of flight control surfaces. Additionally, surface treatments such as coating may be applied to enhance corrosion resistance further.

- Quality Control: The final step in the manufacturing process involves rigorous quality control checks. Each worm gear is tested for dimensional accuracy and mechanical properties to ensure compliance with industry standards. This step is vital as it guarantees that the worm gear in aircraft control systems functions properly under all conditions. Quality assurance processes help to identify any potential defects, ensuring that only high-precision worm gears for aircraft are approved for use in flight control systems.

Worm Gear Supplier in Holland

RP Techniek BV is the sales agent for Ever-power Group in the Netherlands, and we are proud to be one of the top ten worm gear suppliers in the country.

Our products, specifically designed for aircraft control surfaces, exhibit the following qualities:

- High Quality: We ensure that our worm gears meet the highest industry standards, providing reliability and durability.

- Exceptional Craftsmanship: Each product is crafted with precision to guarantee optimal performance in various applications.

- Strong Expertise: Our team possesses deep knowledge and experience in worm gear technology, allowing us to deliver tailored solutions to our clients.

- Outstanding Service: We are committed to providing excellent customer support and after-sales service to ensure complete satisfaction.

Additional information

| Edited | Zqq |

|---|

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...