Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

Winch Planetary Gearbox for Construction Elevators

The Winch Planetary Gearbox for Construction Elevators is a crucial component designed to enhance the performance of construction elevators. This gearbox provides high torque and efficient power transmission, enabling smooth and reliable lifting of materials and personnel at construction sites. Its compact design ensures easy integration with various winch systems, making it an essential part of modern construction equipment for improving safety and productivity during building projects.

Features and Specifications of Winch Planetary Gearbox for Construction Elevators

| Specification | Details |

|---|---|

| Output torque range | 1000-280000 N.m |

| Gear ratios | i=5.3-400 |

| Support | The gearbox has rotating housing flanges to fit winch |

| Applicable motors | Axial piston hydraulic motors, hydraulic orbit motors or others |

| Hydraulic motor options | Pressure relief valve, overcenter valve on request |

| Bearing | Robust bearing system absorbing the forces exerted by the ring gear |

| Brake | Hydraulic released parking brake on request |

| Performance figures | Refer to FEM standards, class M5 (T5-L2) for output max. speeds of 25 rpm |

| Compatibility | Technical data and installation dimensions of the EP400W Series gearbox are same as those of Rexroth GFT…W Series and Bonfiglioli 800 Series, so these three can be used interchangeably |

| Type | Max. torque N.m | Range of ratios (i) | Max. Input speed (rpm) | Braking torque (N.m) |

| EP400W1 | 870 | 6.09 | 1000 | 130 |

| EP401W1 | 1300 | 6.2 | 1000 | 270 |

| EP402W2 | 4000 | 12.4-37.1 | 3500 | - |

| EP403W2 | 4000 | 15.4-40 | 3500 | 270 |

| EP405W | 7000 | 20-80 | 3500 | 270 |

| EP405.4W | 5500 | 26-57 | 3500 | 280 |

| EP406AW | 12500 | 23-220 | 3500 | 430 |

| EP406W | 13000 | 28-140 | 3500 | 430 |

| EP406BW3 | 17500 | 63-136 | 3500 | 430 |

| EP407AW | 18000 | 38-136 | 3500 | 430-530 |

| EP407W3 | 26000 | 63-136 | 3500 | 530 |

| EP410W3 | 37500 | 62-177 | 3500 | 530 |

| EP413W3 | 42500 | 86-172 | 3500 | 610 |

| EP414W3 | 67000 | 76-186 | 3500 | 1200 |

| EP415W3 | 100000 | 81-215 | 3000 | 1200 |

| EP416W3 | 140000 | 87-255 | 3000 | 2000 |

| EP417W3 | 200000 | 123-365 | 3000 | 2000 |

| EP419W3 | 275000 | 161-306 | 2500 | 3000 |

Winch Planetary Gearbox for Construction Elevators - Working Principle

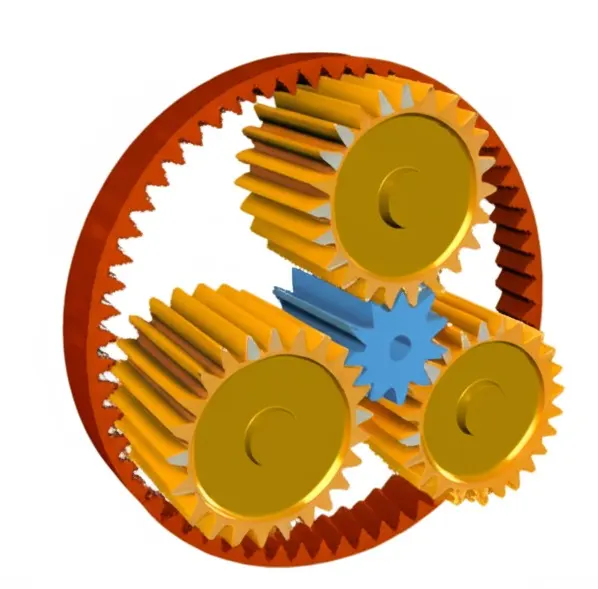

The Winch Planetary Gearbox operates by utilizing a set of gears to transmit power efficiently. Its basic structure consists of a sun gear, planet gears, and a ring gear, allowing for high torque output in a compact design. In construction elevators, this gearbox facilitates smooth and controlled lifting by reducing motor speed while increasing torque. As the motor turns the sun gear, the planet gears revolve around it, engaging with the ring gear to lift heavy loads. This mechanism ensures reliable operation, essential for transporting materials vertically on construction sites.

Advantages of Winch Planetary Gearbox for Construction Elevators

- High Torque and Load Capacity: The multi-tooth engagement design effectively distributes loads, enhancing the overall load-bearing capability.

- Compactness and Space Efficiency: Compared to traditional gearboxes, our planetary gearbox offers significant volume advantages, making it ideal for space-constrained applications.

- Transmission Efficiency: Achieving an efficiency of 97% to 98% in single-stage configurations, and excellent performance in multi-stage setups.

- Durability and Reliability: Even stress distribution ensures a longer lifespan, reducing maintenance needs and downtime.

- Customizability: Tailored to meet diverse winch requirements, allowing adjustments in gear ratios, torque, and installation methods.

Selection Guide for Winch Planetary Gearbox

When selecting a Winch Planetary Gearbox for construction elevators, consider several key factors. Evaluate the power and torque requirements, along with the desired gear ratio and speed. Determine the input and output types, such as spline, hollow, or solid. Assess whether there are external or radial forces acting on the input or output ends. Additionally, take into account the operating temperature, lifespan expectations, and any special requirements like continuous operation or shock loading.

How to Reduce Operating Noise of Winch Planetary Gearbox?

To minimize the operating noise of a winch planetary gearbox used in construction elevators, precision machining and gear design play crucial roles. Utilizing high-quality materials and advanced manufacturing techniques ensures that gear teeth fit together seamlessly, reducing friction and vibrations. Moreover, optimizing gear tooth geometry and employing noise-dampening features can significantly lower the overall noise levels. Regular maintenance, including lubrication, also contributes to smoother operation and noise reduction.

Key Strategies for Noise Reduction

- Precision machining for optimal gear fit

- Advanced gear design to minimize friction

- Use of high-quality materials

- Regular lubrication and maintenance

Winch Planetary Gearbox Manufacturer

RP Techniek is the sales agent for Ever-power Group in the Netherlands, providing expert solutions for various industrial applications. The Winch Planetary Gearbox for Construction Elevators plays a crucial role in ensuring efficient and reliable operation. Its design allows for smooth lifting and lowering of heavy loads, making it an essential component in construction sites.

We encourage our valued customers to customize and purchase these high-quality gearboxes to enhance their operational efficiency and safety. Don't miss the opportunity to improve your equipment with our advanced technology!

Additional information

| Edited | Zqq |

|---|

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...