Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

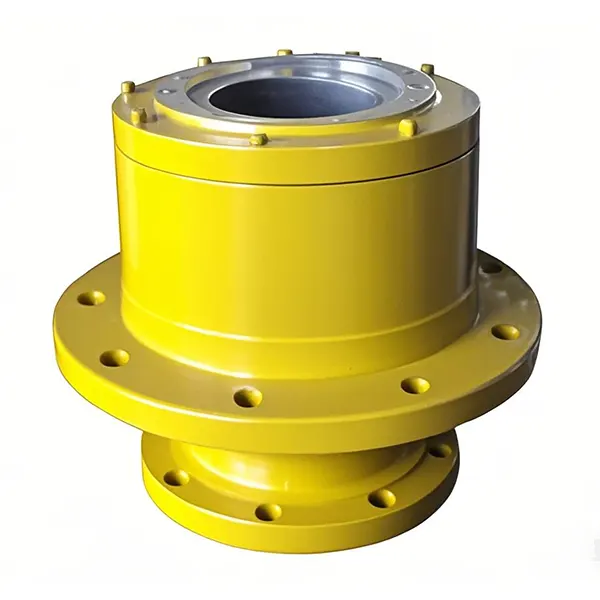

Wheel Drive Planetary Gearbox for Tandem Roller

The Wheel Drive Planetary Gearbox for Tandem Roller is designed for optimal power transmission and operational efficiency in tandem rollers. This gearbox enhances the performance of the roller by providing high torque and precision control, ensuring smooth and even compaction of surfaces. Its robust construction makes it ideal for heavy-duty applications, contributing to the longevity and reliability of road construction projects.

Parameters of Wheel Drive Planetary Gearbox for Tandem Roller

| Specification | Details |

|---|---|

| Output torque range | 1000-60000 N.m |

| Gear ratios | i=5.3-142 |

| Support | The gearbox has rotating housing flanges to fit wheel |

| Applicable motors | Axial piston hydraulic motors, hydraulic orbit motors or others |

| Hydraulic motor options | Pressure relief valve, overcenter valve |

| Bearing | Robust bearing system absorbing the forces exerted by the ring gear |

| Brake | Hydraulically released parking brake |

| Others | EP600L Series wheel drives with manual disconnect application |

| Load capacity | Large radial and axial load capacity due to the use of strong tapered roller bearings |

| Oil seal protection | Reliable oil seal protection, designed according to our field experience |

| Mounting flanges | Universal and SAE input direct mounting flanges |

| Direct mounting | The units are designed for their direct mounting into the wheel rims |

| Interchangeability | Technical data and installation dimension of EP600L Series gearbox are same as those of Rexroth GFT…W Series and Bonfiglioli 600 Series, so these three can be used interchangeably |

| Track drives Type | Max. torque N.m | Range of ratios (i) | Max. Input speed (rpm) | Braking torque (N.m) |

| EP601 L1A | 1750 | 5.77 | 1000 | 450-600 |

| EP603 L2A | 4000 | 19-23-32-40 | 3000 | 210 |

| EP603 L2B | 4000 | 19-23-32-40 | 3000 | 210 |

| EP602 L2 | 5000 | 12.4-25.8 | 3000 | - |

| EP605 L2 | 7000 | 22-27-30-42-53 | 3000 | 220-310 |

| EP606 L2, L3 | 12000 | 30-35-43-68-79 | 3000 | 300-800 |

| EP607 L2, L3 | 17000 | 33-75-108 | 3000 | 300-600 |

| EP609 L2, L3 | 23000 | 33-142 | 3000 | 300-600 |

| EP610 L2, L3 | 30000 | 20-111 | 3000 | 300-800 |

| EP611 L2, L3 | 36000 | 41-47 | 3000 | 300-800 |

| EP613 L3 | 45000 | 108 | 3000 | 300-800 |

| EP615 L3 | 60000 | 108 | 3000 | 300-1000 |

Characteristics and Benefits of Wheel Drive Planetary Gearbox for Tandem Roller

The Wheel Drive Planetary Gearbox for Tandem Roller is designed to enhance the performance and efficiency of tandem rollers in various applications. Here are some of its key characteristics and benefits:

- High Torque Capacity: This gearbox is engineered to deliver high torque, making it ideal for heavy-duty applications and ensuring optimal performance in tough conditions.

- Compact Design: Its compact design allows for easy integration into tandem rollers without compromising on power or efficiency, saving valuable space.

- Durability: Built with high-quality materials, the gearbox is resistant to wear and tear, providing a long operational life even in demanding environments.

- Efficient Power Transmission: The planetary gear configuration ensures smooth and efficient power transmission, reducing energy loss and improving overall operational efficiency.

- Maintenance-Friendly: Designed for easy access to components, the gearbox allows for straightforward maintenance, minimizing downtime and maintenance costs.

- Noise Reduction: Engineered to operate quietly, the gearbox minimizes noise pollution, contributing to a better working environment.

In summary, the Wheel Drive Planetary Gearbox for Tandem Roller combines high performance, durability, and efficiency, making it an excellent choice for operators looking to enhance their equipment's capabilities.

How to Choose a Wheel Drive Planetary Gearbox for Tandem Roller

When selecting a Wheel Drive Planetary Gearbox for a tandem roller, consider the following factors:

- Load Type: Assess the load characteristics, including static and dynamic loads, to ensure the gearbox can handle the required torque and power.

- Operating Environment: Evaluate environmental conditions such as temperature, humidity, and exposure to dust or chemicals, which can affect the gearbox's performance and durability.

- Installation Method: Determine the mounting configuration needed, whether flange connection or shaft output, to ensure compatibility with the tandem roller's design.

Maintenance of Wheel Drive Planetary Gearbox for Tandem Roller

To ensure optimal performance and longevity of the Wheel Drive Planetary Gearbox, follow these maintenance guidelines:

- Regular Inspection: Check for signs of wear, leaks, or unusual noises during operation.

- Lubrication: Ensure that the gearbox is adequately lubricated with the recommended oil type to prevent overheating.

- Cleanliness: Keep the surrounding area clean to avoid contamination of the gearbox.

- Alignment Check: Regularly verify that the gearbox is properly aligned to prevent undue stress on components.

- Temperature Monitoring: Monitor operating temperatures to detect potential issues before they escalate.

Wheel Drive Planetary Gearbox Manufacturer

RP Techniek is the sales agent for Ever-power Group in Australia and the Netherlands, and is one of the top ten suppliers in the Netherlands.

Our Wheel Drive Planetary Gearbox for Tandem Roller provides customized solutions tailored to client specifications. We design gear ratios and mounting methods based on individual customer requirements. Our manufacturing processes ensure high quality through precision machining, guaranteeing low tolerances and extended lifespan. We also offer technical support, providing selection guidance and after-sales services to our clients, which helps to reduce the complexity of the drive system while enhancing the overall performance and reliability of the equipment.

We invite our valued customers to customize their solutions and make a purchase with us today to experience the benefits of our high-quality products and exceptional service.

Additional information

| Edited | Zqq |

|---|

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...