Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

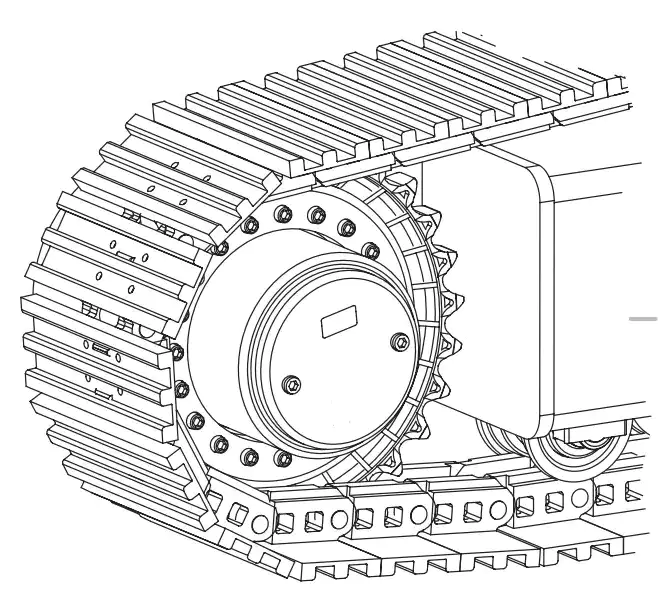

Track Drive for Armored Personnel Carriers (APCs)

The Track Drive Planetary Gearbox for Armored Personnel Carriers (APCs) is engineered for enhanced durability and efficiency. Its compact design allows for seamless integration into APCs, providing superior torque and speed control. The planetary gear system ensures reliable performance under extreme conditions, making it ideal for off-road terrains. This gearbox is crucial for improving mobility and overall operational effectiveness in military applications.

Specifications of Track Drive Planetary Gearbox for Armored Personnel Carriers (APCs)

| Feature | Description |

|---|---|

| Output Torque Range | 1000-450000 N¡¤m |

| Gear Ratios | i = 5.3 - 500 |

| Support | The gearbox has rotating housing flanges to fit tracks |

| Applicable Motors | Axial piston hydraulic motors, hydraulic orbit motors, or others |

| Hydraulic Motor Options | Pressure relief valve, overcenter valve |

| Bearing | Robust bearing system absorbing the forces exerted by the ring gear |

| Brake | Hydraulic released parking brake |

| High Torque and Load Capacities | Designed to carry equipment over the roughest and steepest terrain |

| Motor Mounting | Designed to allow mounting of plug-in motors |

| Compact Design | Integral multi-disc parking brakes, while still keeping the drive compact |

| Material | Steel structure |

| Easy Maintenance | Filling and draining openings are reasonably located for easy reach |

| Front Mechanical Seal | Designed specifically for earth-moving machines |

| Compatibility | Technical data and installation dimensions of EP400T Series gearbox are the same as those of Rexroth GFT¡T Series and Bonfiglioli 700C Series, allowing interchangeability |

| Type | Max. torque N.m | Range of ratios (i) | Max. Input speed (rpm) | Braking torque (N.m.) |

| EP400T1 | 1300 | 6.09 | 1000 | 130 |

| EP401T1 | 2000 | 6.2 | 1000 | 270 |

| EP402T2 | 5000 | 12.4-37.1 | 3500 | - |

| EP403T2 | 7000 | 15.4-40 | 3500 | 270 |

| EP405T | 10000 | 20-80 | 3500 | 270 |

| EP405.4T | 11000 | 26-57 | 3500 | 280 |

| EP406AT | 17000 | 23-220 | 3500 | 430 |

| EP406T | 18000 | 28-140 | 3500 | 430 |

| EP406BT3 | 24000 | 63-136 | 3500 | 430 |

| EP407AT | 26000 | 38-136 | 3500 | 430-530 |

| EP407T3 | 36000 | 63-136 | 3500 | 530 |

| EP410T3 | 50000 | 62-177 | 3500 | 530 |

| EP413T3 | 60000 | 86-172 | 3500 | 610 |

| EP414T3 | 80000 | 76-186 | 3500 | 1200 |

| EP415T3 | 110000 | 81-215 | 3000 | 1200 |

| EP416T3 | 160000 | 87-255 | 3000 | 2000 |

| EP417T3 | 220000 | 123-365 | 3000 | 2000 |

| EP418T3 | 270000 | 166-364 | 3000 | 2000 |

| EP419T3 | 330000 | 161-306 | 2500 | 3000 |

| EP420T4 | 450000 | 296-421 | 2500 | 1700 |

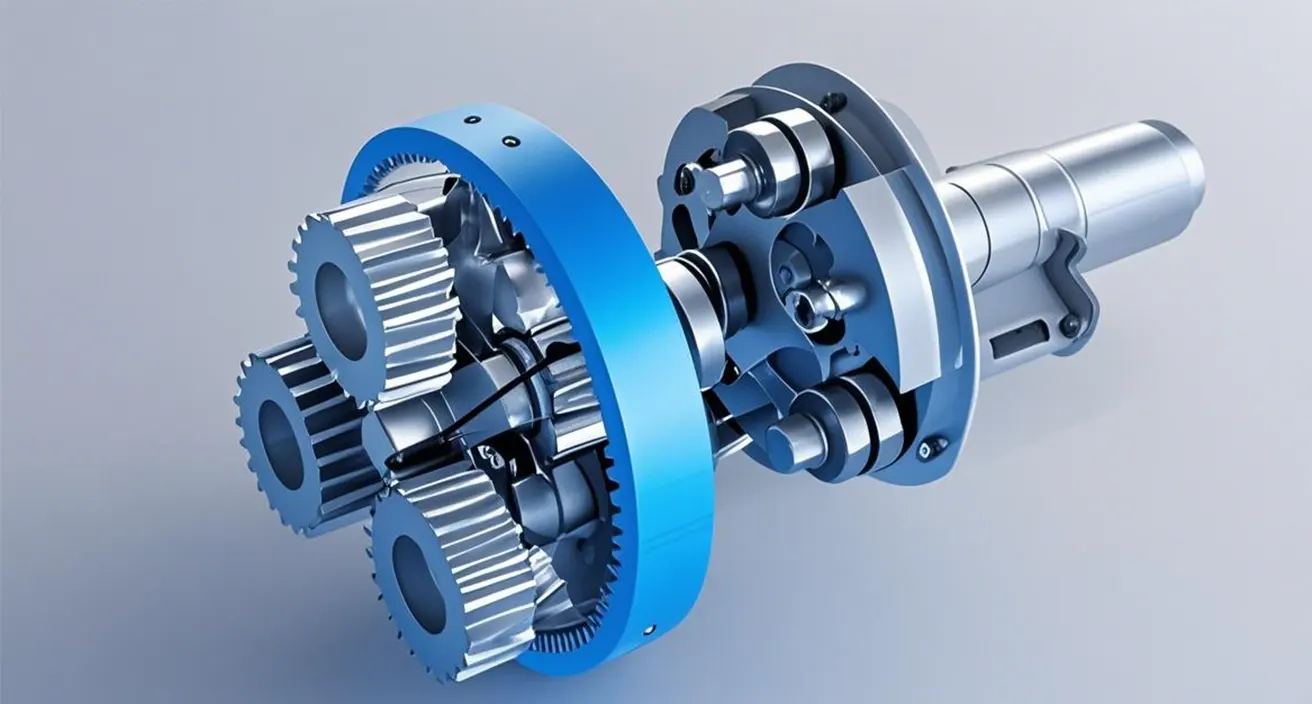

Working Principle of Track Drive Planetary Gearbox for Armored Personnel Carriers (APCs)

The planetary gear system operates by distributing torque across multiple gears. In the Track Drive Planetary Gearbox, the sun gear drives the planet gears, which orbit around it and engage with the ring gear. This configuration allows for a reduction in speed while increasing torque, essential for APCs navigating rugged terrains. The gear ratios can be adjusted to achieve the desired balance of speed and power, optimizing performance in various conditions.

Space Efficiency in Track Drive Planetary Gearboxes for APCs

The design of Track Drive Planetary Gearboxes plays a crucial role in enhancing the space efficiency of armored personnel carriers (APCs). Compared to traditional gearboxes, which often occupy more volume and weight, planetary gear systems consolidate components, enabling a more compact design. This reduction in size not only frees up valuable space for additional equipment and personnel but also contributes to overall vehicle agility and performance. The ability to maintain high torque output in a smaller package is especially beneficial in the tight confines of military vehicles, providing effective power transmission while minimizing the footprint. The streamlined nature of these gearboxes enhances the APC's operational capabilities on various terrains.

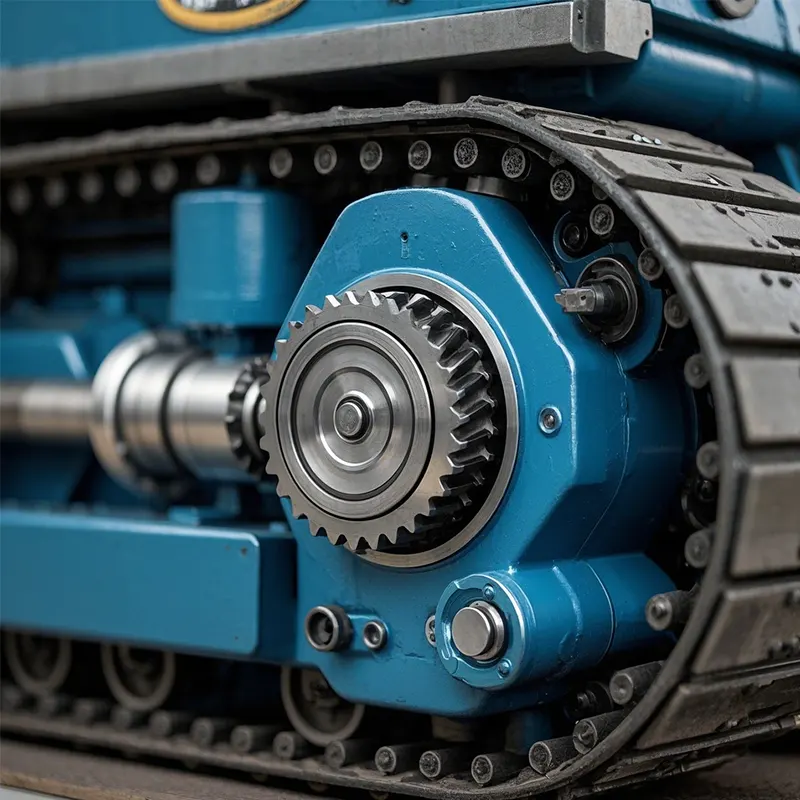

Why High Torque is Essential for Track Drive Planetary Gearboxes in APCs

Track vehicles, such as Armored Personnel Carriers (APCs), require high torque to navigate challenging terrains and carry heavy loads effectively. The high torque helps in overcoming resistance during movement, especially in off-road conditions. Multi-tooth engagement in planetary gearboxes enhances torque density by distributing the load across multiple gears, reducing wear and increasing efficiency. This design ensures that APCs maintain optimal performance while ensuring reliability and longevity, crucial for military operations.

Track Drive Planetary Gearbox Order

We offer not only the Track Drive Planetary Gearbox for Armored Personnel Carriers (APCs) but also customization options to meet your specific needs. To assist with your order, please provide the following information:

- 1. Power or Torque of the planetary gearbox

- 2. Gear Ratio

- 3. Rotational Speed

- 4. Input Type

- 5. Output Type (spline/hollow/solid, etc.)

- 6. Whether there are external/radial forces on the input or output

- 7. Operating Temperature

- 8. Lifespan Requirements

- 9. Special Requirements, such as continuous operation, shock, etc.

Track Drive Manufacturer

RP Techniek is the Dutch sales agent for Ever-power Group, providing high-quality solutions for various applications. Among these solutions, the Track Drive Planetary Gearbox for Armored Personnel Carriers (APCs) plays a crucial role in enhancing mobility and operational efficiency. These gearboxes are designed to withstand the rigorous demands of military operations, ensuring reliability and performance.

We invite all customers to consider customizing and purchasing our top-notch track drive systems, tailored to meet your specific needs. Enhance your vehicle's performance and reliability today!

Additional information

| Edited | Zqq |

|---|

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...