In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

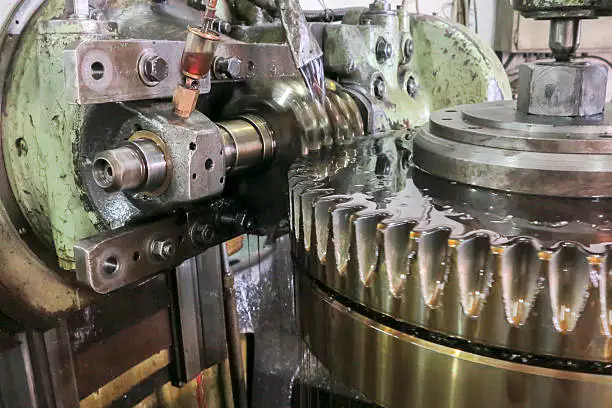

Steering Worm Gear

The steering worm gear is a crucial component in automotive steering systems. Made from high-quality steel, it ensures durability and precision. This gear works in tandem with the steering worm shaft to convert rotational motion into linear movement, facilitating smooth steering control. The steering box worm gear further enhances the overall steering performance.

Details of Steering Worm Gear

| Parameter | Value |

|---|---|

| Material | Alloy Steel |

| Gear Ratio | 1:10 |

| Load Capacity | 500 kg |

| Diameter | 50 mm |

| Length | 150 mm |

| Weight | 2 kg |

| Operating Temperature | -20 to 100 °C |

Features of Steering Worm Gear

- Precision Engineering: The steering worm gear is designed with high precision, ensuring smooth operation and minimal backlash. This helps maintain vehicle control and enhances safety.

- Durability: Made from robust materials, the steering worm shaft and steering box worm gear offer exceptional resistance to wear and tear, prolonging their lifespan even under demanding conditions.

- Compact Design: The design of steering worm gears allows for space-efficient installations, making them ideal for various vehicles while optimizing performance.

How the Steering Worm Gear Works

The steering worm gear is a crucial component in automotive steering systems, providing precise control and smooth operation. It consists of a steering worm shaft that interlocks with a gear, allowing for efficient transmission of rotational motion. As the driver turns the steering wheel, the steering box worm gear converts this motion into lateral movement of the vehicle's wheels. This design not only enhances the responsiveness of steering but also increases stability and safety. The integration of high-quality materials in the steering worm gear ensures durability and reliability over time.

Manufacturing Process of Steering Worm Gear

- Material Selection: The production of a high-quality steering worm gear begins with careful material selection. Typically, high-strength alloy steels are used to ensure durability and resistance to wear. The chosen material must possess the right combination of hardness and toughness, which is critical for the steering worm shaft and steering box worm gear. This choice significantly impacts the operational efficiency and longevity of the steering system.

- Machining: After the material selection, the steering worm gear is shaped using precise machining techniques. This process involves cutting, grinding, and milling the metal to achieve the desired dimensions and tolerances. The machining of the steering worm shaft is particularly critical as it directly influences the meshing with the worm gear. Advanced CNC machines are often used to ensure consistent quality and precision in each steering box worm gear produced.

- Heat Treatment: To enhance the mechanical properties of the steering worm gear, a heat treatment process is applied. This process typically involves hardening the metal by heating it to a specific temperature and then quenching it. This treatment increases the hardness and strength of the steering worm shaft, making it capable of withstanding the stresses encountered during operation. The heat treatment phase is essential for ensuring the longevity of the steering box worm gear.

- Finishing Processes: The final steps in the manufacturing of the steering worm gear involve various finishing processes. These can include polishing, coating, and surface treatments to improve corrosion resistance and reduce friction. A smooth finish on the steering worm shaft and steering box worm gear is necessary for optimal performance, reducing wear and ensuring a smooth steering experience. Quality control measures are implemented at this stage to verify that all specifications are met.

Worm Gear Supplier in Holland

RP Techniek BV is the sales agent for Ever-power Group in the Netherlands, and we are proud to be one of the top ten worm gear suppliers in the country.

Our company specializes in Steering Worm Gear products that stand out for several reasons:

- High Quality: We ensure that our worm gears are manufactured to the highest standards, offering durability and reliability.

- Top-notch Performance: Our products are designed for optimal performance, making them suitable for a variety of applications.

- Strong Reputation: With years of experience in the industry, we have built a solid reputation for excellence and innovation.

- Comprehensive Service: We provide exceptional customer service, ensuring that all client needs are met promptly and efficiently.

Additional information

| Edited | Zqq |

|---|

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...