In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

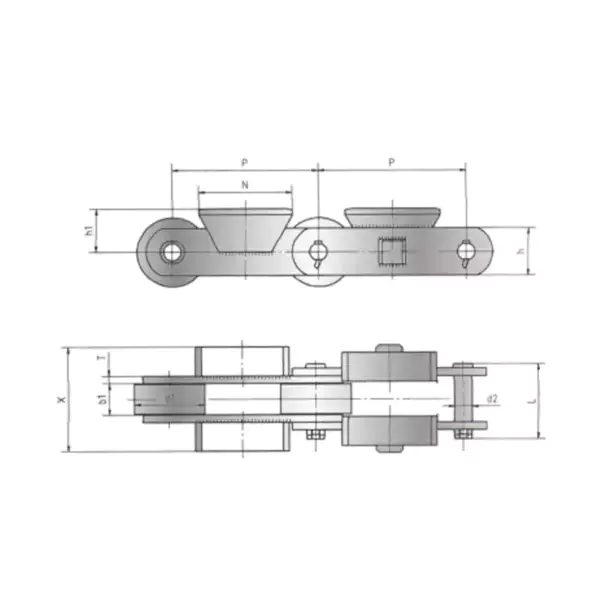

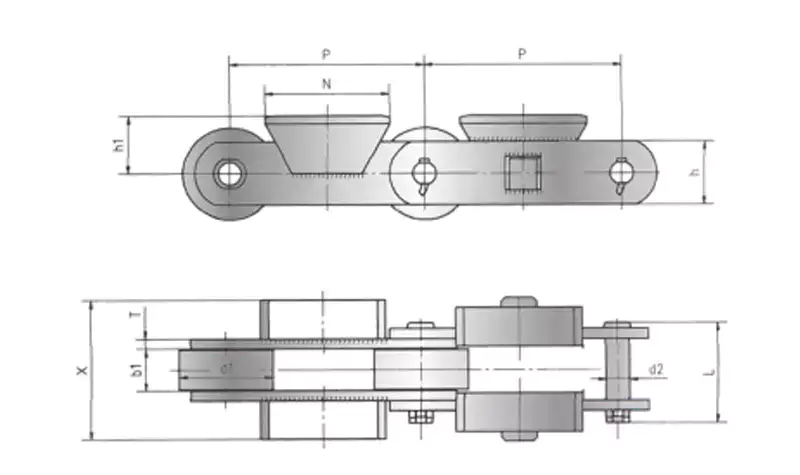

Details of Stainless Steel Metallurgical Welded Plate Conveyor Chain

| Pitch | Width Between Inner Plates |

Roller Diameter |

Pin | Plate | Attachment Dimension | Ultimate Tensile Strength |

Weight Per Meter | ||||

| P | b1 min | d1 max | d2 max | L.max | h | T | n | h1 | X | q | |

| 315 | 47 | 100 | 25 | 117 | 72 | 11 | 200 | 65 | 170 | 315 | 36.5 |

| 250 | 55 | 120 | 30 | 133 | 82 | 13 | 160 | 75 | 181 | 450 | 51.2 |

Introduction

The Stainless Steel Metallurgical Welded Plate Conveyor Chain is utilized in various sectors, including food processing, pharmaceuticals, and chemical manufacturing. It is engineered to carry substantial loads while enduring challenging environmental conditions.

Construction

This chain is composed of premium stainless steel, ensuring remarkable resistance to corrosion and wear. Its design features welded plates that enhance strength and longevity. The configuration of the chain links allows for smooth and quiet functioning.

Applications

The Stainless Steel Metallurgical Welded Plate Conveyor Chain is well-suited for numerous applications, such as:

- Food processing and packaging

- Pharmaceutical manufacturing and packaging

- Chemical production and packaging

- Automotive and machinery production

Advantages

This type of conveyor chain provides various benefits compared to other conveyor chains, including:

- Outstanding resistance to corrosion and wear

- High strength and durability

- Quiet and smooth operation

- Minimal maintenance needs

- Simple cleaning and sanitization

Maintenance

To maintain optimal performance and durability of the Stainless Steel Metallurgical Welded Plate Conveyor Chain, regular upkeep is essential. It is advisable to lubricate the chain frequently and check for any signs of wear or damage. Any components that show damage or wear should be replaced promptly to avert further issues.

Choose Our Stainless Steel Metallurgy Industry Chains

RP Techniek BV serves as the sales representative for Ever-power Group in the Netherlands. We take pride in providing the Stainless Steel Metallurgical Welded Plate Conveyor Chain, which reflects our unique selling propositions. Our focus is on product quality, exceptional customer service, and strong manufacturing capabilities.

Alongside the Stainless Steel Metallurgical Welded Plate Conveyor Chain, we offer a comprehensive range of other stainless steel roller chains. Our varied selection is designed to meet the diverse requirements of various industries.

Our commitment lies in delivering reliable and high-quality solutions to our clients. With extensive experience and expertise in the field, we have built a solid reputation for excellence.

Opt for our stainless steel metallurgy industry chains for superior quality and effectiveness. Contact us today for more information about our offerings and services.

How to Select Suitable Sprockets?

Selecting the appropriate sprockets for your Stainless Steel Metallurgical Welded Plate Conveyor Chain involves several critical considerations. Initially, you must identify the required pitch diameter and the number of teeth necessary for your specific application, based on the desired speed and torque of your conveyor system.

It is also vital to choose sprockets made from high-quality materials, such as stainless steel. This choice guarantees durability and resistance to corrosion, particularly in harsh environments. Stainless steel sprockets provide exceptional strength and reliability, making them ideal for demanding industrial tasks.

Our company offers an extensive array of sprockets to satisfy your specific needs. Whether you require single or double-strand sprockets, we have an assortment of types and sizes available. Our sprockets are engineered for optimal performance and longevity, ensuring the seamless functioning of your conveyor system.

Additional information

| Edited by | Zqq. |

|---|

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...