In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

Details of Stainless Steel Metallurgical Water Slot Chain for Disc Casting Machine SSP125

Introduction

The SSP125 Stainless Steel Metallurgical Water Slot Chain is an essential part utilized in the production of steel and other metallic materials. Its design facilitates a steady water flow to cool the molds, aiding in the solidification of molten metal, which leads to the creation of high-quality, defect-free items. This article discusses the features and advantages of the SSP125 Water Slot Chain.

Construction

Constructed from premium stainless steel, the SSP125 Water Slot Chain is resistant to corrosion and built for longevity. It includes a series of water slots that permit a constant flow to the molds, promoting uniform cooling and solidification of the molten metal. This chain can endure high temperatures and pressures, making it versatile for various metallurgical operations.

Design

The design of the SSP125 Water Slot Chain is fine-tuned for optimal performance and effectiveness. It incorporates interlocking links that ensure a steady and smooth water flow to the molds, which guarantees uniform cooling and solidification. Additionally, the chain is designed for easy installation and maintenance, reducing downtime and enhancing productivity.

Benefits

Improved Product Quality

With its ability to provide an unbroken flow of water to the molds, the SSP125 Water Slot Chain guarantees uniform cooling and solidification of the molten metal. This leads to superior, defect-free products, enhancing overall quality and lowering scrap rates.

Increased Productivity

The SSP125 Water Slot Chain's efficient design enables quicker cooling and solidification processes, which shortens cycle times and boosts productivity. Its straightforward installation and maintenance further reduce downtime, leading to increased operational efficiency.

Cost Savings

Adopting the SSP125 Water Slot Chain can yield substantial cost savings. Improvements in product quality and reductions in scrap rates enable manufacturers to cut down on material and production expenses. Moreover, enhanced productivity coupled with reduced downtime can contribute to additional savings.

Applications

The SSP125 Water Slot Chain is applicable across various metallurgical tasks, such as steel production, aluminum casting, and copper smelting. Its ability to handle high temperatures and pressures makes it suitable for use in challenging environments.

Conclusion

The Stainless Steel Metallurgical Water Slot Chain for Disc Casting Machine SSP125 is a vital component in the production of high-quality metals. Its robust construction, effective design, and significant benefits make it indispensable for metallurgical processes. By choosing the SSP125 Water Slot Chain, manufacturers can enhance product quality, boost productivity, and reduce production costs.

Choose Our Stainless Steel Metallurgy Industry Chains

RP Techniek BV serves as the sales representative for Ever-power Group in the Netherlands. We pride ourselves on providing top-tier products and outstanding services. One of our premier offerings is the Stainless Steel Metallurgical Water Slot Chain for Disc Casting Machine SSP125.

Our key advantages include:

1. Exceptional Product Quality: Our stainless steel metallurgy industry chains are crafted from high-grade materials, ensuring their durability and reliability in rigorous industrial applications.

2. Outstanding Customer Service: We focus on customer satisfaction and offer superior pre- and post-sales support. Our committed team is always available to assist with any questions or technical support you may require.

3. Production Capability: Our advanced manufacturing facilities and innovative production methods allow us to meet large-scale demands without sacrificing quality or efficiency.

In addition to the SSP125 chain, we provide a broad array of other stainless steel roller chains. Whether you need chains for industrial equipment, conveyor systems, or other uses, we have the right solution for your specific requirements.

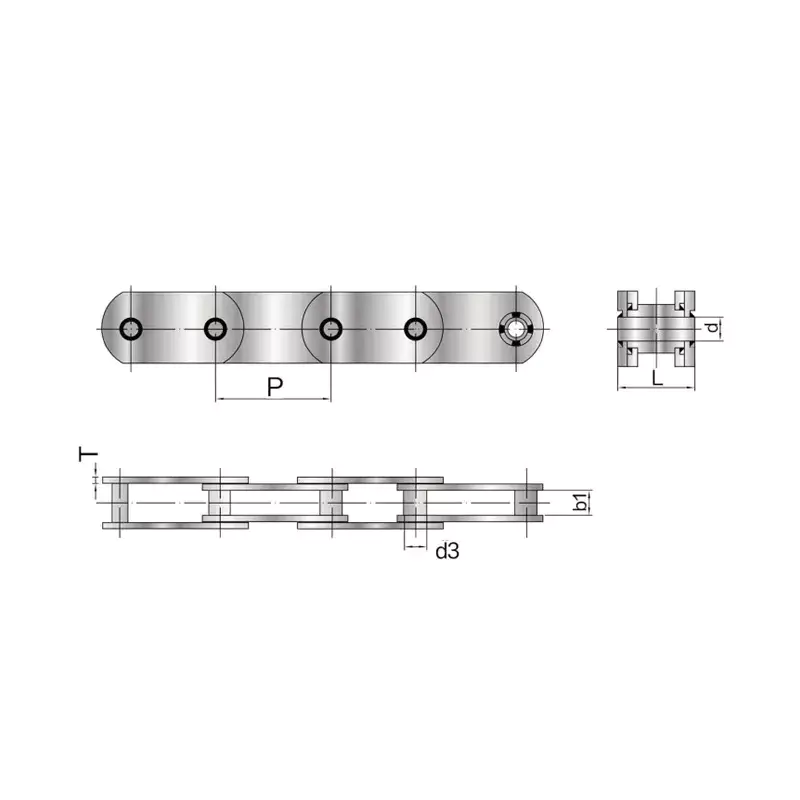

To showcase our products, here’s an image of our chain:

Select our stainless steel metallurgy industry chains for unparalleled quality, dependable performance, and excellent customer support. Reach out to us today to discuss your needs and experience the superior service of RP Techniek BV and the Ever-power Group.

How to Select Suitable Sprockets?

When choosing appropriate sprockets for your Stainless Steel Metallurgical Water Slot Chain for Disc Casting Machine SSP125, there are several crucial factors to keep in mind. It is vital to select sprockets that match the chain's pitch and width to ensure a snug fit, preventing slippage or damage.

Another key point is the number of teeth on the sprocket. This count influences the machine's gear ratio, which significantly affects its performance. Selecting the correct gear ratio is essential for achieving peak efficiency and output.

Our company offers a wide selection of sprockets for various needs and applications. Constructed from high-quality materials, our sprockets are built for durability and longevity. Recognizing the importance of appropriate sprocket selection for your machinery, we provide expert advice and support to help you make informed decisions.

In summary, when choosing sprockets for your Stainless Steel Metallurgical Water Slot Chain for Disc Casting Machine SSP125, it is critical to consider compatibility, gear ratio, and durability. Our company has a range of top-notch sprockets to fulfill your specific needs and criteria.

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...