In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

Details about Stainless Steel Metallurgical Waste Material Conveyor Chain SSWM100

Introduction

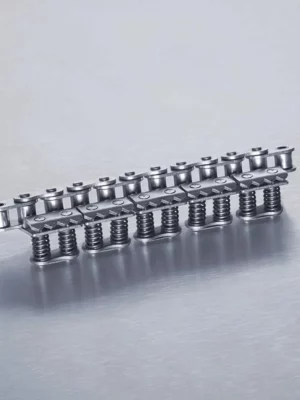

The Stainless Steel Metallurgical Waste Material Conveyor Chain SSWM100 is specifically engineered for the efficient transportation of metallurgical waste. Crafted from premium stainless steel, it offers exceptional durability and resistance to corrosion. This chain is built to function optimally in extreme environments, enduring high temperatures and substantial loads. It plays a critical role in industries focused on metal production, including steel and aluminum manufacturing.

Structure and Components

The construction of the Stainless Steel Metallurgical Waste Material Conveyor Chain SSWM100 comprises several key components such as the outer link plate, inner link plate, pins, bushings, and rollers. The outer link plate, made from high-grade stainless steel, forms a robust foundation for the chain. The inner link plate, also stainless steel, connects to the outer link plate via pins and bushings. Rollers are situated between the inner and outer plates to minimize friction and wear, enhancing the chain's longevity.

Features and Benefits

- Manufactured from high-quality stainless steel for superior durability and resistance to corrosion

- Engineered to function in demanding environments, withstanding high temperatures and heavy loads

- Includes rollers and bushings that help reduce friction and wear, promoting extended service life

- Designed for easy installation and maintenance, which minimizes downtime and operational costs

- Versatile compatibility with various conveyor types, making it suitable for multiple applications

- Operates with low noise, contributing to a more pleasant working atmosphere

Applications

The Stainless Steel Metallurgical Waste Material Conveyor Chain SSWM100 is extensively utilized in the metallurgical sector for transporting waste materials. It is ideal for operations in steel mills, aluminum fabrication plants, copper refineries, and other metal production environments. The chain is capable of handling diverse waste materials such as slag, dust, and metal shavings.

Maintenance and Service

Regular maintenance is vital for the optimal functioning and longevity of the Stainless Steel Metallurgical Waste Material Conveyor Chain SSWM100. This includes lubricating the chain to minimize friction and wear, checking for any signs of damage, and adjusting the chain tension for proper operation. It is advisable to periodically replace the chain to avoid potential failures and reduce downtime.

Conclusion

The Stainless Steel Metallurgical Waste Material Conveyor Chain SSWM100 represents a dependable and durable choice for transporting waste materials within the metallurgical industry. Its design accommodates harsh environmental conditions and heavy loads, making it a crucial component for metal production facilities. With its durable stainless steel construction, low noise operation, and straightforward maintenance, this chain provides a cost-effective and adaptable solution for waste material handling.

Choose Our Stainless Steel Metallurgy Industry Chains

RP Techniek BV serves as the Dutch sales agent for Ever-power Group. We take pride in offering the Stainless Steel Metallurgical Waste Material Conveyor Chain SSWM100, which highlights our unique advantages and underscores the outstanding quality and service we deliver. Our robust production capabilities further reinforce our dedication to excellence.

Alongside the Stainless Steel Metallurgical Waste Material Conveyor Chain SSWM100, we provide an extensive selection of other stainless steel roller chains for sale. Our broad inventory allows us to meet the varied needs of our customers. Every chain is designed and manufactured to the highest standards, ensuring durability and reliability in challenging applications.

By opting for our stainless steel chains, customers benefit from their corrosion resistance and high-temperature endurance, thereby ensuring optimal performance in demanding environments. Our chains are meticulously crafted from premium-grade stainless steel, offering superior strength and durability.

At Ever-power Group, we pride ourselves not only on delivering exceptional products but also on providing outstanding customer service. Our dedicated team is always available to assist clients with inquiries, offer technical support, and ensure a smooth purchasing experience.

With our comprehensive product range, unwavering quality commitment, and unparalleled customer service, we are your perfect partner for all stainless steel chain requirements. Contact us today for more information about our offerings or to discuss your specific needs.

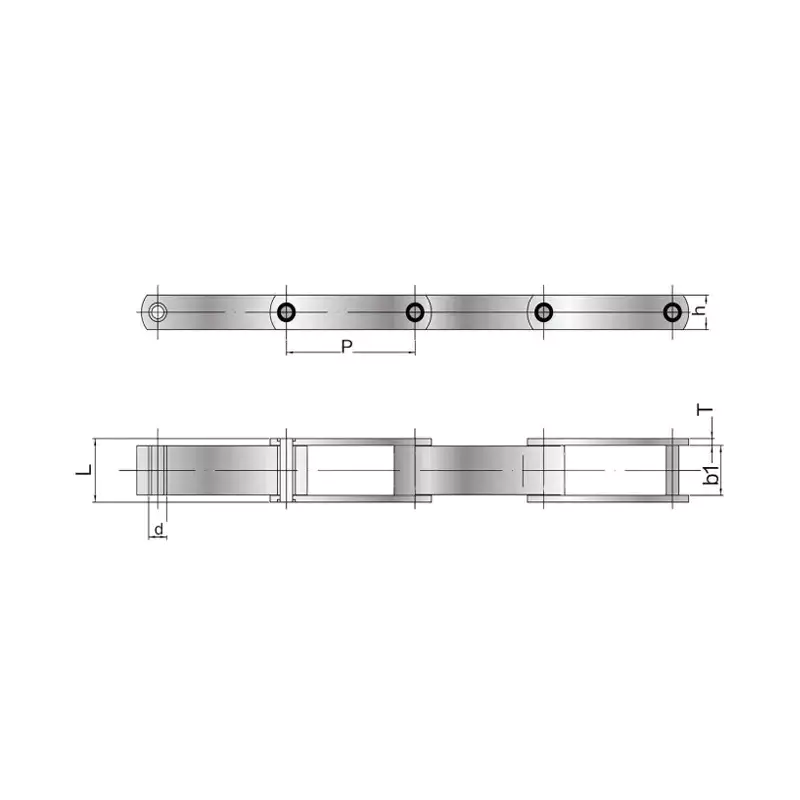

How to Select Suitable Sprockets?

To choose the appropriate sprockets for the Stainless Steel Metallurgical Waste Material Conveyor Chain SSWM100, there are several key factors to consider. First, identify the required pitch diameter and the number of teeth based on your application. This will depend on the speed and load specifications of your conveyor system.

Next, evaluate the material and quality of the sprocket. Stainless steel sprockets are optimal for applications requiring corrosion resistance, such as waste material conveyors. Our company offers a comprehensive range of high-quality sprockets, including stainless steel variants, to cater to diverse customer needs.

Additionally, consider the hub type and mounting method. Depending on your specific conveyor setup, you may need a particular hub style, such as a bored-to-size or a stock bore sprocket. Our extensive inventory includes various hub types to accommodate a wide range of requirements.

Finally, ensure the correct alignment and tension of both the chain and sprockets to prevent premature wear. Routine maintenance and inspection are also advisable to extend the lifespan of your sprockets and sustain optimal performance.

Please refer to the image below for a visual overview of our sprockets:

For any additional questions or help in selecting the right sprockets, please do not hesitate to reach out. We are dedicated to providing a broad selection of high-quality sprockets to fulfill your requirements.

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...