In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

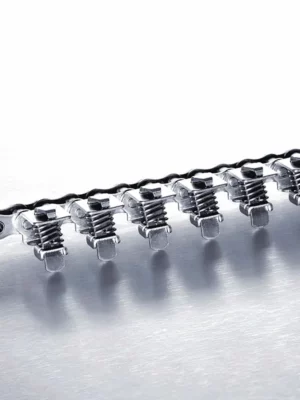

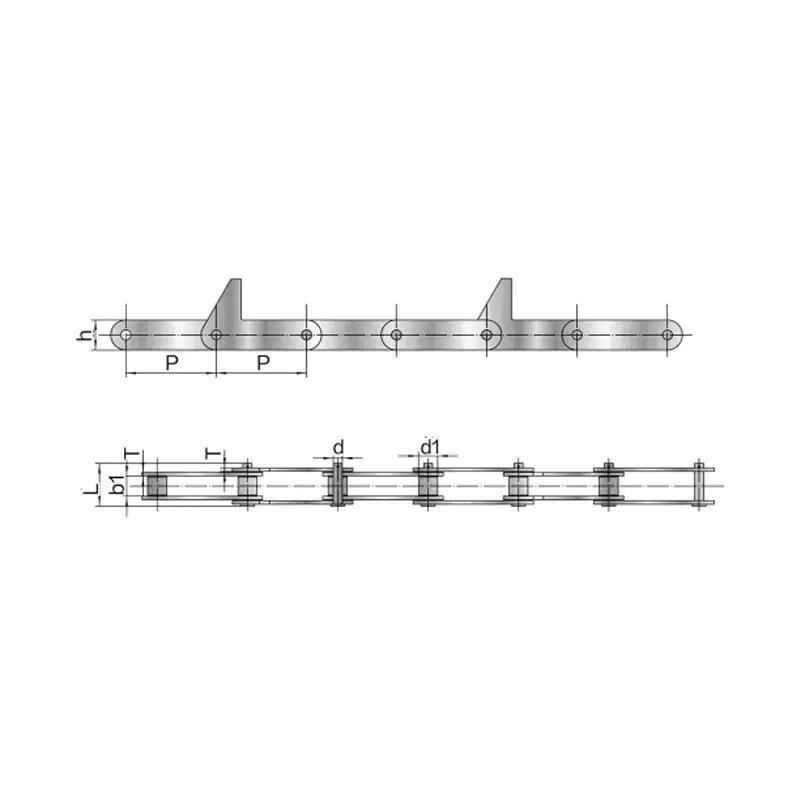

Details of Stainless Steel Metallurgical Washing Conveyor Chain SSWC100

Stainless Steel Metallurgical Washing Conveyor Chain SSWC100

1. Introduction

The SSWC100 Stainless Steel Metallurgical Washing Conveyor Chain is a premium solution specifically crafted for metallurgical washing processes. Renowned for its strength, efficiency, and reliability, it is the optimal choice for sectors that demand a sturdy conveyor chain.

2. Key Features

The SSWC100 stands out from other conveyor chains in the market due to its innovative design and construction, offering several significant features:

- Stainless Steel Construction: Crafted from high-grade stainless steel, this chain ensures superior corrosion resistance and long-lasting performance.

- High Load Capacity: The SSWC100 can manage substantial loads while maintaining its structural integrity.

- Smooth Operation: Engineered for quiet and efficient operation, minimizing wear on the machinery.

- Easy Maintenance: The design facilitates easy upkeep, featuring quick-access pins and removable links.

3. Applications

The SSWC100 is versatile and suitable for various applications within the metallurgical sector, including:

- Steel Manufacturing: Perfect for transporting steel materials during the washing procedure, ensuring effective and comprehensive cleaning.

- Foundries: Commonly utilized in foundries for moving molten metal and other substances, the chain endures extreme temperatures and challenging conditions.

- Aluminum Production: The SSWC100 is ideal for conveying aluminum items, attributed to its corrosion-resistant features.

4. Installation

Installing the SSWC100 is a simple task requiring careful attention to detail. Follow these instructions for a successful setup:

- Prepare the Conveyor: Ensure the conveyor is clean and devoid of any debris that could disrupt the installation.

- Attach the Chain: Position the SSWC100 on the conveyor, aligning the links with the sprockets.

- Secure the Chain: Connect the chain to the conveyor using the provided pins or connectors for a secure attachment.

- Tension the Chain: Adjust the chain tension according to the manufacturer's specifications to promote optimal performance and longevity.

5. Maintenance

Regular maintenance is crucial for ensuring the SSWC100's durability and peak performance. Here are some maintenance recommendations:

- Regular Cleaning: Keep the chain free from dirt, debris, or residues that may build up during operation.

- Lubrication: Apply an appropriate lubricant on a routine basis to reduce friction and prevent premature wear.

- Inspection: Frequently check the chain for any damage or deterioration, such as bent or broken links.

- Replacement: Promptly replace any damaged or excessively worn components to avoid further complications.

6. Conclusion

The Stainless Steel Metallurgical Washing Conveyor Chain SSWC100 offers a dependable and robust solution for a variety of metallurgical washing needs. Its remarkable attributes, straightforward installation, and minimal maintenance requirements make it a favored choice in industries seeking efficient and resilient conveyor systems. Invest in the SSWC100 for enduring performance and assurance.

Choose Our Stainless Steel Metallurgy Industry Chains

RP Techniek BV serves as the authorized sales representative for Ever-power Group in the Netherlands. Our commitment lies in supplying high-quality stainless steel metallurgy industry chains, including the exceptional Stainless Steel Metallurgical Washing Conveyor Chain SSWC100.

Our chains are manufactured using cutting-edge technology and high-quality stainless steel, ensuring durability and longevity. The corrosion-resistant properties of our chains make them suitable for demanding environments typical in the metallurgy sector.

Furthermore, we take pride in offering outstanding customer service. Our team of qualified professionals is always available to provide expert guidance and technical support to help you find the ideal product for your requirements.

At RP Techniek BV, we possess the capability to manufacture an extensive range of stainless steel roller chains tailored for diverse applications. Our production facilities are equipped with state-of-the-art technology, and our skilled professionals are dedicated to producing high-quality chains that adhere to international standards.

Select us for all your stainless steel metallurgy industry chain requirements, and we assure you will be satisfied. Reach out to us today to discover more about our offerings.

How to Select Suitable Sprockets?

Choosing the appropriate sprockets for the Stainless Steel Metallurgical Washing Conveyor Chain SSWC100 involves several considerations. Firstly, it is essential to assess the desired speed ratio and torque requirements for your specific application. This evaluation will aid in selecting the right pitch diameter and number of teeth for the sprocket.

Additionally, the material of the sprocket should be taken into account. For the SSWC100, stainless steel sprockets are the best option. They provide excellent corrosion resistance and durability, making them suitable for applications in harsh environments or those involving chemicals.

Moreover, our company is proud to offer a broad selection of sprockets to meet various needs. We provide various types, including different tooth profiles and hub configurations. Our products are meticulously designed and manufactured to ensure reliable performance and durability.

In summary, selecting the right sprockets for the Stainless Steel Metallurgical Washing Conveyor Chain SSWC100 involves evaluating the desired speed ratio, torque requirements, and material compatibility. Our company presents a diverse range of high-quality sprockets to ensure top performance and customer satisfaction.

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...