Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

Details

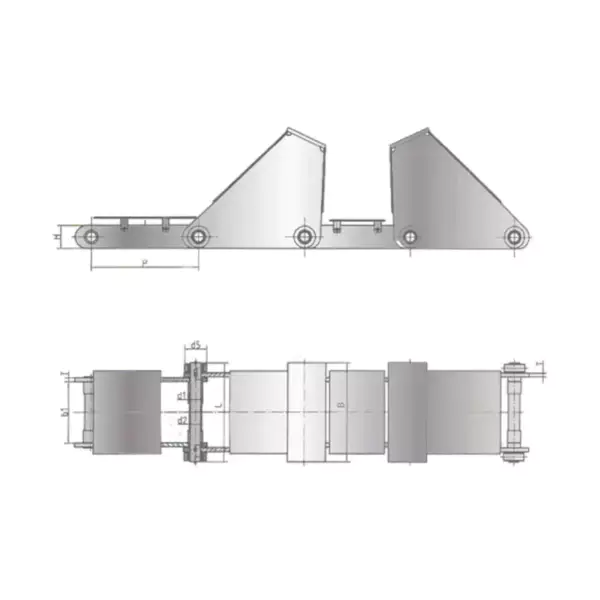

| Pitch | Width Between Inner Plates |

Roller Diameter |

Pin | Plate | Attachment Dimension | Type | Ultimate Tensile Strength |

||||||

| P | b1 min |

d1 max |

d2 | L | H | T | d3 | S | d4 | X | d5 | ||

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | KN | |||

| 135 | 135 | 50 | 26 | 95.5 | 80 | 8 | 80 | 115 | 26 | / | / | A | 320 |

| 135 | 135 | 50 | 26 | 95.5 | 80 | 8 | 80 | 140 | 26 | / | / | A | 320 |

| 135 | 135 | 60 | 30 | 200 | 75 | 12 | 60 | 100 | 20 | 175 | 85 | B | 350 |

| 160 | 160 | 50 | 25 | 177 | 85 | 9 | 70 | 130 | 25 | 148 | 95 | B | 320 |

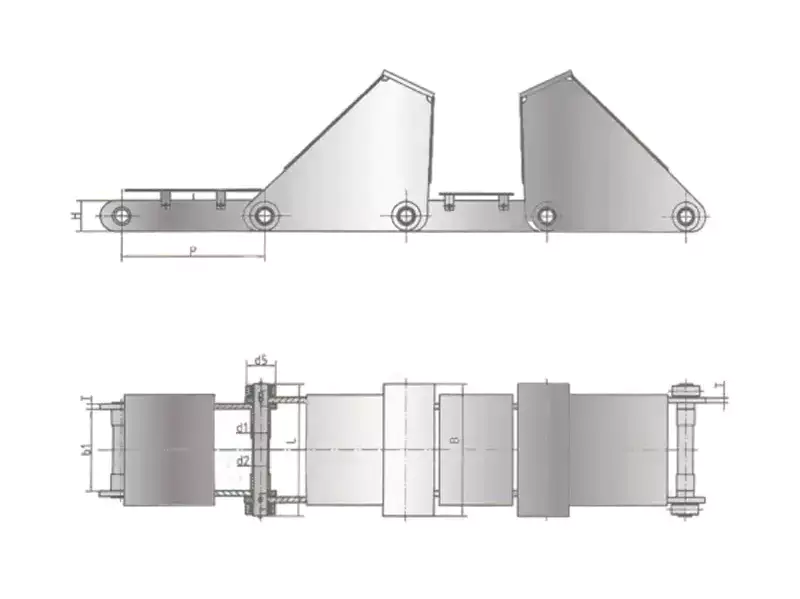

| Pitch | Width Between Inner Plates |

Roller Diameter | Pin | Plate | Ultimate Tensile Strength |

Weight Per Meter | ||||

| P | b1 | d1 | d5 | d2 | L | H | T | B | min | q |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | KN | kq/m |

| 830 | 484 | 110 | 170 | 80 | 780 | 180 | 30 | 780 | 3000 | 410 |

| 900 | 463 | 130 | 200 | 100 | 849 | 200 | 36 | 780 | 3600 | 770 |

| 1000 | 484 | 110 | 170 | 80 | 778 | 180 | 30 | 800 | 3000 | 350 |

Overview

Stainless Steel Metallurgical Steel Coil Conveyor Chain is a high-quality, durable chain designed for use in metallurgical steel processing plants. This chain is specifically engineered to withstand the harsh environments found in steel processing facilities while maintaining a long service life. Its stainless steel construction makes it resistant to corrosion and able to withstand high temperatures, making it an ideal choice for high-temperature applications.

Benefits of Stainless Steel Metallurgical Steel Coil Conveyor Chain

Corrosion Resistance

With its stainless steel construction, this chain is highly resistant to corrosion, making it ideal for use in harsh environments where exposure to moisture and chemicals is common. This resistance to corrosion allows the chain to maintain its structural integrity and prolongs its lifespan, reducing the need for frequent replacements.

High-Temperature Resistance

Stainless Steel Metallurgical Steel Coil Conveyor Chain is designed to withstand high temperatures, making it ideal for use in applications where heat is a factor. The chain's ability to maintain its strength and integrity at high temperatures ensures reliable operation and reduces downtime caused by chain failure.

Durability

This chain is designed to be highly durable, capable of withstanding the harsh conditions found in steel processing plants. Its robust construction and high-quality materials make it resistant to wear and damage, ensuring a long service life and reducing the need for frequent replacements.

Reduced Maintenance

Due to its high durability and resistance to corrosion and high temperatures, Stainless Steel Metallurgical Steel Coil Conveyor Chain requires less maintenance than traditional chains. This reduces downtime and maintenance costs, making it an excellent choice for steel processing facilities looking to increase efficiency and reduce operating costs.

Customizability

This chain can be customized to meet specific requirements, such as size, strength, and material. This allows it to be tailored to meet the needs of a particular application, ensuring optimal performance and reliability.

Eco-Friendly

Stainless Steel Metallurgical Steel Coil Conveyor Chain is an eco-friendly option, as it is recyclable and does not produce harmful byproducts. Its ability to withstand high temperatures also makes it an ideal choice for energy-efficient operations, helping to reduce carbon emissions and overall environmental impact.

Choose Our Stainless Steel Metallurgy Industry Chains

RP Techniek BV is the official sales agent for Ever-power Group in the Netherlands. We take pride in offering top-quality stainless steel metallurgical steel coil conveyor chains. Our unique selling points revolve around our exceptional product quality and unmatched services. With our extensive expertise and robust production capabilities, we ensure that our chains meet and exceed industry standards.

In addition to our stainless steel metallurgy industry chains, we also offer a wide range of other stainless steel roller chains. Our diverse selection caters to various industrial applications and guarantees reliable performance and longevity. Trust us to provide you with the perfect chain solution for your unique requirements.

Choose RP Techniek BV as your trusted partner for all your stainless steel chain needs. Contact us today to discuss your project and discover the exceptional quality and service we offer.

How to Select Suitable Sprockets?

To select a suitable sprocket for your Stainless Steel Metallurgical Steel Coil Conveyor Chain, you need to consider a few factors. Firstly, determine the pitch of your chain and select a sprocket with a matching pitch. Secondly, consider the number of teeth on the sprocket and ensure that it is compatible with the number of teeth on the chain. Finally, take into account the bore size and keyway of the sprocket to ensure it fits properly on your shaft.

At our company, we offer a wide variety of sprockets to meet your needs. We have different sizes, pitches, and tooth counts to match your specific conveyor chain. Our sprockets are made from high-quality materials, including stainless steel, to ensure durability and longevity.

Please see the attached image for an example of the sprockets we offer.

Additional information

| Edited by | Zqq. |

|---|

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...