Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

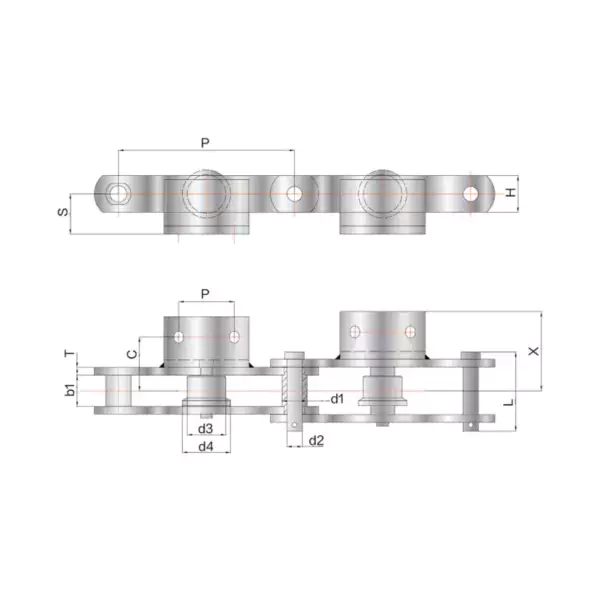

Details of Stainless Steel Metallurgical Slag Conveyor Chain

| Pitch | Width Between Inner Plates |

Bush Diameter |

Pin | Plate | Attachment Dimension | Ultimate Tensile Strength |

|||||||

| Diameter | Length | Height | Thickness | ||||||||||

| P | b1 min |

d1 max |

d2 max |

max | H max |

T | X | C | g | S | d3 | d4 | min |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | KN |

| 365 | 65 | 52 | 31.6 | 16.2 | 76.2 | 16 | 160 | 120 | 115 | 72 | 80 | 100 | 450 |

Choose Our Stainless Steel Metallurgy Industry Chains

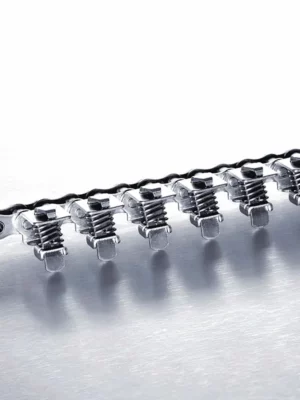

RP Techniek BV serves as the authorized sales representative for Ever-power Group in the Netherlands. We are excited to present our Stainless Steel Metallurgical Slag Conveyor Chain, showcasing our distinct advantages and our dedication to high-quality products and outstanding service.

Our chains are produced with premium stainless steel, ensuring exceptional durability, resistance to corrosion, and dependable performance in rigorous industrial settings. With our vast experience in the metallurgy sector, we assure that our chains comply with top-tier standards and provide optimal outcomes.

In addition to our Stainless Steel Metallurgical Slag Conveyor Chain, we provide a broad selection of other stainless steel roller chains tailored for various uses. Ranging from standard models to custom-made solutions, our chains are meticulously designed to fulfill the unique requirements of our clients.

We take immense pride in our manufacturing capabilities, equipped with cutting-edge facilities and a proficient team committed to achieving excellence. Our production processes conform to industry-leading benchmarks, ensuring consistent quality and accuracy.

Opt for our stainless steel chains for their remarkable performance, extensive durability, and the assurance that comes from partnering with a reputable sales agent like RP Techniek BV. Reach out to us today to discuss your stainless steel chain needs and discover the reliability and expertise we provide.

How to Select Suitable Sprockets?

Selecting the appropriate sprockets for a Stainless Steel Metallurgical Slag Conveyor Chain involves several essential factors. First, it is crucial to identify the pitch diameter or the sprocket size, which should correspond with the chain’s pitch. Additionally, the number of teeth on the sprocket must align with the chain's dimensions and speed specifications.

Another significant factor is the material composition of the sprocket. Stainless steel sprockets are strongly recommended for applications involving metallurgical slag due to their excellent resistance to corrosion and high temperatures. They enhance longevity and durability, ensuring consistent performance in challenging conditions.

Our company provides an extensive array of sprockets to meet diverse needs. Our inventory includes various sizes, tooth counts, and materials, including stainless steel sprockets tailored for metallurgical slag conveyor chains. With our wide-ranging product selection, we strive to satisfy the specific demands of our clients and deliver reliable solutions.

Additional information

| Edited by | Zqq. |

|---|

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...