Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

Details of Stainless Steel Metallurgical Scraper Chain

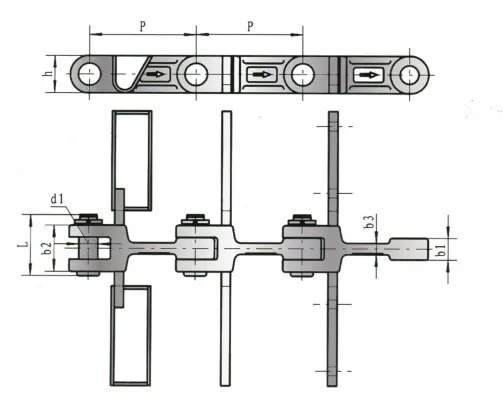

| P | d1(mm) | b1(mm) | b2(mm) | b3(mm) | f(mm) | L(mm) |

| 142 | 25 | 19 | 43 | 12.2 | 35 | 69 |

| P | d1(mm) | b1(mm) | b2(mm) | b3(mm) | L(mm) |

| 142 | 25 | 29 | 62 | 15 | 82 |

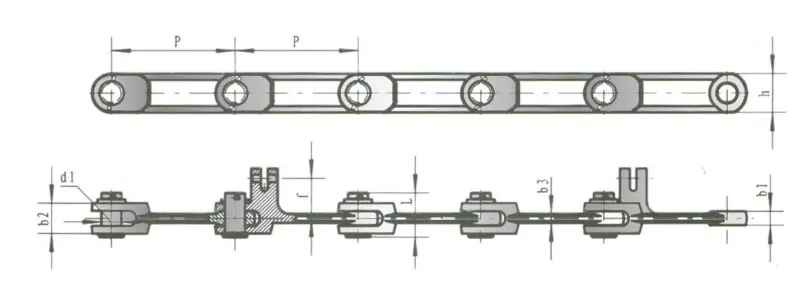

| P | d1(mm) | h(mm) | b1(mm) | b2(mm) | b3(mm) | f(mm) | L(mm) |

| 200 | 25 | 50 | 24 | 58 | 17 | 38 | 75 |

| P | d1(mm) | h(mm) | b1(mm) | b2(mm) | b3(mm) | f(mm) | L(mm) |

| 200 | 32 | 64 | 23 | 50 | 15 | 66 | 69 |

Introduction

The Stainless Steel Metallurgical Scraper Chain is engineered to excel in metallurgical applications, providing exceptional durability and high quality. Its remarkable strength and resistance to corrosion guarantee reliable performance even in challenging conditions.

Metallurgical Scraper Chain Features

Enhanced Material Composition

Our Stainless Steel Metallurgical Scraper Chain is made from a distinctive combination of stainless steel alloys, chosen for their superior mechanical characteristics and corrosion resistance. This innovative material formulation ensures outstanding performance and extended lifespan, even under extreme temperatures and harsh chemicals.

Precision Engineering

Every link in our scraper chain is precisely manufactured to ensure a perfect fit and seamless operation. The sophisticated design includes specialized elements like reinforced pins and bushings for optimal load-bearing capabilities and wear resistance. This meticulous engineering guarantees high performance and reduces maintenance needs.

High Load Capacity

The Stainless Steel Metallurgical Scraper Chain is designed to support heavy loads effortlessly. Its sturdy design and advanced metallurgy deliver outstanding strength, enabling it to endure the tough demands of metallurgical processes. Whether transporting molten metal or abrasive materials, this chain ensures consistent and dependable performance.

Corrosion Resistance

Corrosion presents a significant challenge in metallurgical settings. Our Stainless Steel Metallurgical Scraper Chain is specifically developed to address this concern. The stainless steel alloys utilized in its construction provide exceptional corrosion resistance, promoting long-term durability and minimizing the chance of chain failure. This makes it an excellent choice for environments exposed to corrosive materials.

Low Maintenance

Thanks to its top-tier design and premium materials, our Stainless Steel Metallurgical Scraper Chain requires very little maintenance. The precisely engineered links minimize friction and wear, prolonging the chain's service life while decreasing the frequency of replacements. This not only conserves time and effort but also lessens downtime and production expenses.

Versatile Applications

The Stainless Steel Metallurgical Scraper Chain is widely utilized across various metallurgical sectors. Whether in steel mills, foundries, or other metal processing facilities, this chain is adept at transporting hot metal, slag, or other abrasive substances. Its adaptability, along with its robustness and reliability, makes it a vital component in the metallurgical field.

Choose Our Stainless Steel Metallurgy Industry Chains

RP Techniek BV serves as the Dutch sales representative for Ever-power Group. We take pride in promoting this esteemed company throughout the Netherlands. Our focus is on the Stainless Steel Metallurgical Scraper Chain, which highlights our unique selling propositions and reflects the high quality and service standards we deliver. With our extensive knowledge and cutting-edge production capabilities, we guarantee that our chains adhere to the top industry benchmarks.

In addition to the Stainless Steel Metallurgical Scraper Chain, we provide an extensive range of other stainless steel roller chains. Our varied offerings cater to multiple needs and specifications, ensuring that you can find the ideal chain for your application. We emphasize customer satisfaction and aim to surpass expectations with every product we offer.

Count on RP Techniek BV and Ever-power Group for all your stainless steel chain requirements. Reach out to us today to discover more about our products and how we can assist you.

How to Select Suitable Sprockets?

When choosing the appropriate sprockets for your Stainless Steel Metallurgical Scraper Chain, several factors must be considered. First, identify the pitch diameter and the necessary number of teeth for your specific application, as this will depend on your machinery's speed and torque requirements.

Next, selecting the right material for your sprockets is crucial. Stainless Steel sprockets provide excellent corrosion resistance and durability, making them a suitable option for industrial use. Our company offers a diverse selection of sprockets crafted from various materials to meet different customer needs.

Additionally, consider the type of hub attachment needed for your sprockets. We have multiple hub styles available, including plain bore, tapered bore, and keyway options, to ensure compatibility with your equipment.

Finally, for optimal efficiency and extended lifespan, regular maintenance and lubrication of your sprockets are necessary. Our team can offer advice on the best maintenance practices to guarantee your sprockets function smoothly.

Additional information

| Edited by | Zqq. |

|---|

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...