Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

Details of Stainless Steel Metallurgical Lifting Chain

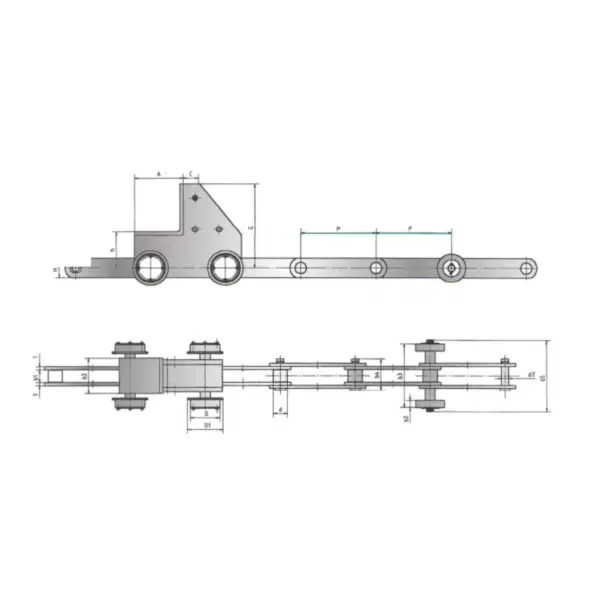

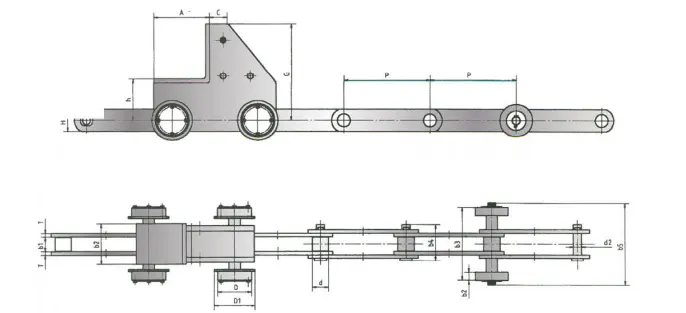

| Pitch | Width Between Inner Plates |

Roller Diameter |

Pin Diameter |

Plate Thickness |

Attachment Dimension | Ultimate Tensile Strength |

||||||||||

| b1 | d1 | d2 | b4 | b5 | H | T | h | A | C | G | b2 | D | D1 | b3 | KN | |

| 315 | 55 | 60 | 30 | 133 | 310 | 82 | 13 | 170 | 205 | 70 | 360 | 180 | 125 | 149 | 274 | 450 |

Introduction

Stainless steel metallurgical lifting chains are robust chains specifically designed for heavy lifting tasks across various sectors. Constructed from premium stainless steel, these chains are not only durable but also resistant to corrosion, ensuring a long service life. This article offers an in-depth overview of the product, highlighting its characteristics and potential uses.

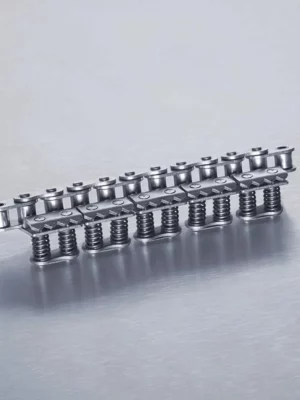

Construction and Material

Stainless steel metallurgical lifting chains comprise multiple parts, such as links, pins, and rollers. Each component is crafted from high-quality stainless steel, providing remarkable strength and resistance to corrosion. Rigorous testing is conducted to verify that these chains comply with the necessary standards regarding load capacity and durability.

Features

The stainless steel metallurgical lifting chain boasts numerous exceptional attributes that render it suitable for heavy-duty lifting tasks. Key features include high strength, remarkable corrosion resistance, durability, and wear resistance. Additionally, these chains withstand high temperatures and chemical exposure, making them perfect for challenging working conditions.

Applications

These stainless steel metallurgical lifting chains are utilized in a variety of industries, such as construction, mining, oil and gas, marine, and manufacturing. They play a crucial role in heavy lifting operations, including the transportation of heavy machinery, lifting cargo on ships, and hoisting materials in construction and mining environments.

Maintenance

Proper maintenance is vital for the longevity of stainless steel metallurgical lifting chains. Regular inspections for wear and tear are essential, and any damaged components should be replaced without delay. Additionally, regular lubrication is necessary to prevent rust and corrosion.

Choose Our Stainless Steel Metallurgy Industry Chains

RP Techniek BV serves as the authorized distributor for Ever-power Group in the Netherlands. We are committed to providing high-quality Stainless Steel Metallurgical Lifting Chains tailored to the specific demands of the industry.

Our chains are produced using premium stainless steel, ensuring exceptional durability and strength. With an emphasis on precision craftsmanship, our chains deliver consistent performance even in the most extreme conditions.

At RP Techniek BV, we recognize the importance of delivering excellent service to our clients. Our knowledgeable team is ready to help you find the ideal chain solution for your metallurgy industry needs.

In addition to the Stainless Steel Metallurgical Lifting Chains, we offer a comprehensive selection of other stainless steel roller chains. Our diverse range is designed to accommodate various industrial requirements, ensuring you find the right chain for your specific applications.

With our extensive manufacturing capabilities, we efficiently meet your chain needs without compromising quality.

How to Select Suitable Sprockets?

When selecting the appropriate sprockets for your Stainless Steel Metallurgical Lifting Chain, several key factors must be taken into account. First and foremost, it is important to ensure that the sprocket aligns with the pitch of the lifting chain. The pitch refers to the distance between adjacent chain links, making it essential to select a sprocket that matches this measurement for proper engagement.

Another critical factor is the number of teeth on the sprocket. The tooth count impacts the speed ratio between the driving and driven sprockets. Choosing a sprocket with the correct number of teeth is vital for achieving the desired speed and torque output.

Additionally, the sprocket material significantly affects its performance and longevity. Stainless steel sprockets are an excellent option for applications needing high strength and corrosion resistance. They are particularly suitable for environments that are exposed to moisture, chemicals, or extreme heat.

Our company offers an extensive selection of sprockets to meet various requirements and applications. Whether you need standard sprockets, custom-made options, or sprockets with special coatings, we have a solution for you. Our sprockets are carefully engineered and manufactured to ensure outstanding performance, reliability, and durability.

Additional information

| Edited by | Zqq. |

|---|

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...