Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

Details of Stainless Steel Metallurgical Heavy Duty Flat Top Conveyor Chain

| Pitch | Plate | Flat Plate Thickness | Type A | Type B | Ultimate Tensile Strength | ||||||||||||

| Height | Thickness | ||||||||||||||||

| P | H | H1 | T | T1 | W | B | d | D | F | W | B | d0 | d1 | D | F | D1 | min |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | KN |

| 75 | 76 | 45 | 5 | 6 | 35 | 80 | 11.1 | 60 | 30 | 28 | 130 | 36 | 17 | 60 | 18 | 18 | 145 |

| 150 | 90 | 50 | 6 | 8 | 40 | 90 | 12.7 | 70 | 35 | 32 | 140 | 42 | 20 | 65 | 22 | 21 | 175 |

| 200 | 95 | 55 | 8 | 9 | 45 | 100 | 15.8 | 80 | 40 | 34 | 150 | 50 | 20 | 65 | 25 | 25 | 200 |

| 250 | 104 | 64.5 | 9.5 | 9 | 51.4 | 110 | 19.1 | 95 | 44 | 36 | 160 | 55 | 25 | 70 | 25 | 30 | 250 |

| 350 | 108 | 68 | 9.5 | 10 | 64 | 115 | 22.2 | 100 | 46 | 40 | 170 | 55 | 30 | 72 | 29 | 32 | 330 |

| 450 | 127 | 89 | 10 | 12 | 65 | 145 | 25.4 | 105 | 52 | 40 | 180 | 60 | 30 | 72 | 29 | 34 | 400 |

| 550 | 150 | 105 | 14 | 15 | 80 | 100 | 28.3 | 110 | 60 | 50 | 220 | 70 | 40 | 90 | 40 | 42 | 650 |

| 400 | 182 | 140 | 10 | 12 | 75 | 240 | 60 | 26 | 120 | 45 | 30 | 530 | |||||

| 300 | 171 | 94 | 16 | 16 | 82 | 210 | 38.2 | 150 | 70 | 850 | |||||||

| 500 | 171 | 94 | 16 | 16 | 82 | 210 | 38.2 | 150 | 70 | 850 | |||||||

| 600 | 208 | 112 | 16 | 16 | 88 | 220 | 45.2 | 160 | 75 | 1200 | |||||||

Introduction

The Stainless Steel Metallurgical Heavy Duty Flat Top Conveyor Chain is a high-quality and durable chain designed specifically for heavy-duty industrial applications in the metallurgical industry. This chain is made of stainless steel, ensuring excellent corrosion resistance and longevity even in harsh operating environments.

1. Superior Strength and Load Capacity

With its robust construction and advanced metallurgical design, this conveyor chain offers superior strength and load capacity. Its heavy-duty flat top design allows it to handle heavy loads with ease, making it ideal for transporting materials and products in demanding industrial settings.

2. Enhanced Wear Resistance

The Stainless Steel Metallurgical Heavy Duty Flat Top Conveyor Chain is engineered to withstand high levels of wear and tear. Its surface is specially treated to enhance wear resistance, ensuring long-lasting performance even in abrasive environments.

3. Precision Engineering for Smooth Operation

This conveyor chain is meticulously engineered to deliver smooth and reliable operation. Each link is precisely manufactured to ensure optimal fit and minimal friction, reducing noise and vibration during operation.

4. Corrosion Resistance for Harsh Environments

Thanks to its stainless steel construction, this conveyor chain exhibits exceptional resistance to corrosion. It is capable of withstanding exposure to moisture, chemicals, and high temperatures, making it suitable for use in harsh industrial environments.

5. Easy Maintenance and Longevity

The Stainless Steel Metallurgical Heavy Duty Flat Top Conveyor Chain requires minimal maintenance, contributing to its overall longevity and cost-effectiveness. It is designed for easy cleaning and lubrication, ensuring optimal performance and extending the chain's service life.

6. Versatile Applications

Due to its high strength, durability, and corrosion resistance, this conveyor chain is versatile and can be used in a wide range of applications. It is commonly employed in industries such as metallurgy, mining, automotive, and food processing, where reliable and efficient material handling is essential.

Overall, the Stainless Steel Metallurgical Heavy Duty Flat Top Conveyor Chain is a top choice for industrial applications that require a robust, long-lasting, and high-performing conveyor chain. Its superior strength, wear resistance, and corrosion resistance make it an ideal solution for demanding environments, ensuring smooth and efficient material handling operations.

Choose Our Stainless Steel Metallurgy Industry Chains

RP Techniek BV is the authorized sales agent of Ever-power Group in the Netherlands. We specialize in supplying high-quality Stainless Steel Metallurgical Heavy Duty Flat Top Conveyor Chains that are built to last. Our unique selling points include exceptional product quality, reliable services, and a testament to our strong manufacturing capabilities.

Our Stainless Steel Metallurgical Heavy Duty Flat Top Conveyor Chains are designed to withstand the demanding conditions of the metallurgy industry. With their exceptional durability and strength, our chains ensure smooth and efficient operation, reducing downtime and increasing productivity.

In addition to the mentioned chains, we also offer a wide range of other stainless steel roller chains for various applications. Whether you require chains for food processing, automotive, or industrial applications, we have you covered.

With a commitment to customer satisfaction, we strive to provide the highest level of service and support. Our experienced team is always ready to assist you in finding the perfect stainless steel chains for your specific needs.

Choose Ever-power Group for your stainless steel metallurgy industry chains and experience the reliability and quality that sets us apart.

How to Select Suitable Sprockets?

When it comes to Stainless Steel Metallurgical Heavy Duty Flat Top Conveyor Chain, selecting the right sprockets is crucial for optimal performance. The first thing to consider is the pitch, or the distance between the chain's pins. It's essential to choose sprockets with the same pitch as the chain for a proper fit and smooth operation.

Another factor to consider is the number of teeth on the sprocket. A smaller sprocket with fewer teeth will turn faster than a larger sprocket with more teeth. The ideal sprocket size will depend on the conveyor's speed, load, and desired output.

At our company, we offer a wide range of sprockets to suit your needs. We have various pitch sizes, tooth counts, and materials, including stainless steel and carbon steel sprockets. Our knowledgeable experts can help you select the right sprockets for your conveyor system.

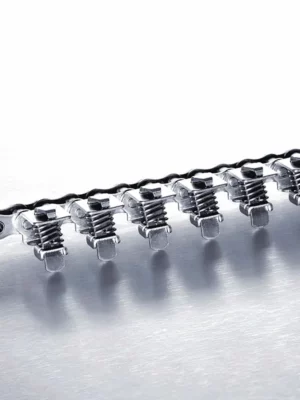

Please see the attached image for a sample of the sprockets we offer.

Additional information

| Edited by | Zqq. |

|---|

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...