In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

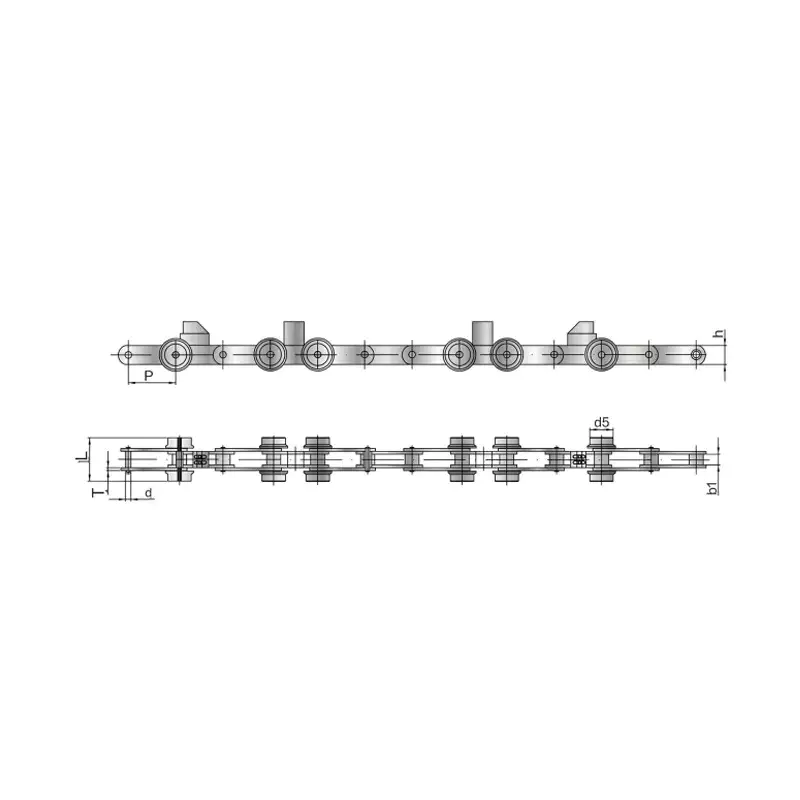

Details of Stainless Steel Metallurgical Electrolysis Anode Chain for Horizontal Conveyor SSEA125

Introduction

The Stainless Steel Metallurgical Electrolysis Anode Chain for Horizontal Conveyor SSEA125 is an innovative solution tailored for the metallurgical sector. Crafted from premium stainless steel, it boasts exceptional durability and resistance to rust and corrosion. Specifically designed for horizontal conveyors, this chain facilitates the transportation of anodes during the electrolysis process, making it a vital element for effective operation.

Material

This chain is constructed from high-grade stainless steel, known for its superior mechanical characteristics and corrosion resistance. The steel incorporates alloying elements such as chromium, nickel, and molybdenum, enhancing its strength and durability against corrosive environments. Such composition guarantees that the chain can endure the challenging conditions typically found in the metallurgical field, including exposure to extreme temperatures and harmful chemicals.

Design

The design of the Stainless Steel Metallurgical Electrolysis Anode Chain for Horizontal Conveyor SSEA125 is informed by extensive industry experience. It is engineered to be robust, long-lasting, and corrosion-resistant. Its distinctive design allows it to accommodate anodes of varying sizes and weights. Additionally, the chain is designed for straightforward installation and maintenance, which minimizes downtime and maximizes operational efficiency.

Benefits

- Durable: Constructed from high-quality stainless steel, the SSEA125 chain is built to last and resist wear.

- Corrosion-resistant: Its corrosion-resistant properties ensure that it can endure the demanding environments of the metallurgical industry.

- Easy to install: The chain’s design facilitates quick installation, helping to reduce downtime and improve productivity.

- Low maintenance: With minimal maintenance needs, the chain helps save both time and costs.

- Flexible: Capable of handling anodes of diverse sizes and weights, the chain is versatile for multiple applications.

Applications

The Stainless Steel Metallurgical Electrolysis Anode Chain for Horizontal Conveyor SSEA125 plays a crucial role in the metallurgical industry, particularly in electrolysis operations. It is designed to transport anodes of various dimensions, which are essential for the extraction of metals such as aluminum, copper, and zinc. As a key component of the electrolysis process, the quality of this chain is vital for achieving successful outcomes.

Conclusion

The Stainless Steel Metallurgical Electrolysis Anode Chain for Horizontal Conveyor SSEA125 represents a high-quality solution intended for the metallurgical industry. Its premium stainless steel construction ensures durability and corrosion resistance. Designed for easy installation and upkeep, it helps enhance productivity while being critical to the electrolysis process's success.

Choose Our Stainless Steel Metallurgy Industry Chains

RP Techniek BV proudly serves as the authorized sales representative for Ever-power Group in the Netherlands. We are committed to offering the Stainless Steel Metallurgical Electrolysis Anode Chain for Horizontal Conveyor SSEA125, highlighting our unique advantages and showcasing the exceptional quality and service our products provide. With robust manufacturing capabilities, we guarantee that our chains adhere to the highest industry standards.

In addition to the SSEA125, we provide an extensive selection of other stainless steel roller chains for various applications. Our broad array caters to diverse requirements, ensuring that we have the ideal chain for your specific industrial or specialized needs.

How to Select Suitable Sprockets?

When selecting appropriate sprockets for the Stainless Steel Metallurgical Electrolysis Anode Chain for Horizontal Conveyor SSEA125, there are several important factors to consider. Firstly, it is essential to identify the chain's pitch and choose a sprocket that matches this pitch for optimal engagement. Furthermore, the number of teeth on the sprocket and the bore diameter must be selected with precision to ensure a proper fit and suitable operating conditions.

Our company offers a comprehensive range of sprockets in different sizes, pitches, and tooth counts tailored to meet the specific needs of our clients. Each sprocket is crafted from high-quality materials and manufactured to rigorous standards to guarantee durability and reliability, even in demanding applications.

Please see the image below for an example of a sprocket that we offer:

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...