In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

Stainless Steel Metallurgical Bucket Elevator Chain Details

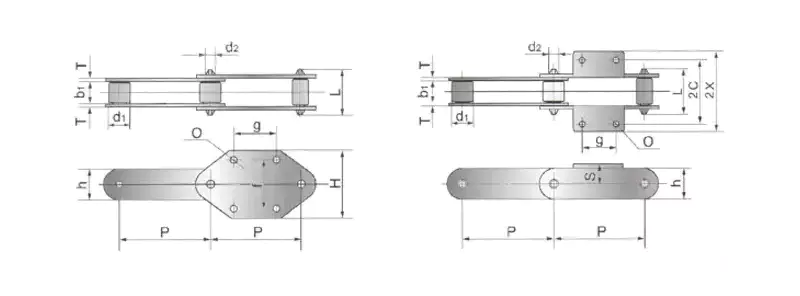

| Pitch | Width Between Inner Plates | Roller Diameter | Pin | Plate | G attachment | Ultimate Tensile Strength | |||||

| P | b1 min | d1 max | d2 max | I max | h max | T | H | f | g | o | min |

| mm | mm | mm | m | mm | mm | mm | mm | mm | mm | mm | KN |

| 152.4 | 36.5 | 35 | 15.5 | 90 | 50 | 8 | 110 | 70 | 75 | 14 | 200 |

| 200 | 51.8 | 42 | 19.1 | 120 | 60 | 10 | 125 | 80 | 100 | 14 | 320 |

| 200 | 58 | 50 | 20 | 126 | 75 | 10 | 125 | 80 | 100 | 14 | 420 |

| 250 | 67.4 | 63.5 | 31.75 | 146 | 90 | 12 | 150 | 110 | 150 | 17 | 800 |

| Pitch | Width Between Inner Plates | Roller Diameter | Pin | Plate | G attachment | Ultimate Tensile Strength | ||||||

| P | b1 min | d1 max | d2 max | I max | h max | T | 2X | 2C | S | g | o | min |

| mm | mm | mm | m | mm | mm | mm | mm | mm | mm | mm | mm | KN |

| 100 | 37 | 36 | 16 | 80 | 40 | 6 | 130 | 96 | 36 | 30 | 13 | 160 |

| 101.6 | 54 | 25.4(Ì×) | 16 | 110 | 40 | 10 | 164 | 134 | 36 | 44 | 12 | 280 |

| 101.6 | 27 | 26.5 | 11.5 | 70 | 35 | 6 | 120 | 80 | 35 | 35 | 10 | 120 |

| 152.4 | 36.5 | 35 | 15.5 | 90 | 50 | 8 | 150 | 110 | 80 | 80 | 10 | 200 |

| 200 | 57.6 | 48.5 | 19.1 | 120 | 75 | 10 | 200 | 160 | 125 | 125 | 12 | 380 |

| 315 | 68 | 70 | 36 | 147 | 100 | 14 | 250 | 200 | 85 | 85 | 24 | 1250 |

Introduction

The Stainless Steel Metallurgical Bucket Elevator Chain is a high-quality and reliable chain specifically designed for elevating materials in metallurgical processes. With its superior strength and durability, this chain is capable of handling heavy loads and operating in harsh environments, making it an ideal choice for various industrial applications.

Key Features

1. High Strength: The stainless steel construction of this bucket elevator chain provides exceptional strength, allowing it to withstand heavy loads and operate reliably in demanding conditions.

2. Corrosion Resistance: The chain is made from high-grade stainless steel, ensuring excellent resistance to corrosion caused by chemicals, moisture, and other harsh elements commonly encountered in metallurgical processes.

3. Wear Resistance: The chain is designed to withstand the abrasive nature of materials being transported, offering exceptional wear resistance and prolonging its service life.

4. Smooth Operation: With precise engineering and high-quality craftsmanship, this chain guarantees smooth and efficient operation, minimizing downtime and maximizing productivity.

5. Easy Maintenance: The chain's design allows for easy maintenance, reducing downtime and ensuring optimal performance throughout its lifespan.

6. Customizable Options: We offer a range of customizable options, including different chain lengths, attachments, and accessories, to meet specific application requirements.

Applications

The Stainless Steel Metallurgical Bucket Elevator Chain finds its applications in various industries, including:

- Metallurgical plants

- Mining operations

- Cement production

- Chemical processing

- Food processing

Choose Our Stainless Steel Metallurgy Industry Chains

RP Techniek BV, the sales agency of Ever-power Group in the Netherlands, proudly presents the Stainless Steel Metallurgical Bucket Elevator Chain. Our company stands out with its unique selling points, emphasizing product quality, exceptional service, and showcasing our manufacturing capabilities.

In addition to the Stainless Steel Metallurgical Bucket Elevator Chain, we offer a wide range of other stainless steel roller chains. With our diverse selection, we ensure that we can meet various industry needs.

How to Select Suitable Sprockets?

When it comes to choosing the right sprockets for your Stainless Steel Metallurgical Bucket Elevator Chain, there are a few key factors to consider. Firstly, you need to take into account the pitch diameter and number of teeth of the sprocket. These specifications should match the requirements of your chain to ensure smooth operation and optimal performance.

Additionally, it is crucial to consider the material of the sprocket. Stainless steel sprockets are highly recommended for applications where corrosion resistance and durability are essential. They are ideal for industries such as food processing, pharmaceuticals, and chemical manufacturing.

At our company, we offer a wide range of sprockets to meet various needs. Our selection includes different types, sizes, and tooth configurations to suit different chain applications. Whether you require standard or custom-made sprockets, we have you covered.

With our high-quality sprockets, you can ensure reliable and efficient operation of your Stainless Steel Metallurgical Bucket Elevator Chain. Contact us today to explore our extensive range and find the perfect sprockets for your needs!

Additional information

| Edited by | Zqq. |

|---|

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...