In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

Details of Stainless Steel Metallurgical Anode Scrap Conveyor Chain SSP100B

Introduction

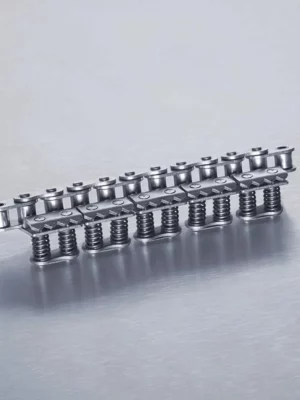

The Stainless Steel Metallurgical Anode Scrap Conveyor Chain SSP100B is specifically engineered for the metallurgical sector. Designed to manage anode scrap, a residual product from the aluminum and zinc smelting processes, this conveyor chain is constructed from premium stainless steel, ensuring exceptional durability and resistance to both wear and corrosion.

Features

High-strength construction

Built with robust stainless steel, the SSP100B boasts outstanding durability and wear resistance. This quality makes it an optimal choice for challenging environments prone to corrosion and degradation.

Precision manufacturing

The SSP100B is crafted with meticulous precision, ensuring that every link is consistent in size and shape. This uniformity allows for smooth operation and minimizes the potential for jamming or other issues associated with poorly manufactured chains.

Easy maintenance

Designed for convenience, the SSP100B requires minimal maintenance, eliminating the need for extensive lubrication or complicated upkeep. This efficiency saves both time and costs while ensuring the chain remains in peak working condition for extended durations.

Applications

Aluminum smelting

The SSP100B is perfectly suited for aluminum smelting applications. It effectively manages anode scrap, a byproduct of the smelting process, moving this material efficiently and dependably through the production workflow.

Zinc smelting

Additionally, the SSP100B is appropriate for zinc smelting operations. It efficiently transports dross, the byproduct of the zinc smelting process, throughout the production line.

Other applications

Beyond aluminum and zinc smelting, the SSP100B can be utilized in various industrial settings where a robust and durable conveyor chain is necessary. Its stainless steel design makes it ideal for environments where wear and corrosion are prevalent.

Choose Our Stainless Steel Metallurgy Industry Chains

RP Techniek BV serves as the official sales representative of Ever-power Group in the Netherlands. We are committed to providing high-quality stainless steel chains for the metallurgical industry, particularly the Stainless Steel Metallurgical Anode Scrap Conveyor Chain SSP100B.

Our focus on superior product quality and outstanding customer service sets us apart. We prioritize addressing the unique requirements of our clients in the stainless steel sector, ensuring that our chains are both durable and reliable, capable of enduring the rigorous conditions of metallurgical processes.

In addition to the SSP100B chain, we offer a comprehensive range of other stainless steel roller chains. Our extensive selection is designed to meet diverse applications and specifications, ensuring that our customers find the ideal chain solution for their needs.

With our robust production capacity, we can accommodate large orders to satisfy the demands of various stainless steel manufacturers. Our expertise in manufacturing allows us to uphold the highest quality standards while delivering chains promptly.

Choose RP Techniek BV as your preferred supplier of stainless steel chains for the metallurgy industry and experience the reliability, strength, and performance that our products deliver. Reach out to us today to discuss your needs and let us provide you with the optimal chain solution for your operations.

How to Select Suitable Sprockets?

When selecting appropriate sprockets for your Stainless Steel Metallurgical Anode Scrap Conveyor Chain SSP100B, several factors should be taken into account. The foremost consideration is the number of teeth on the sprocket, which must correspond to the number of links on the chain. This alignment ensures a snug fit on the sprocket, minimizing wear and extending the chain's lifespan.

Another critical factor is the material used for the sprocket. For the SSP100B chain, stainless steel sprockets are advisable due to their strength, corrosion resistance, and ability to endure elevated temperatures.

We offer a variety of sprockets for sale, including single, double, and triple strand options. Additionally, we can create custom sprockets tailored to your specific requirements.

By choosing the right sprockets for your SSP100B chain, you can facilitate smooth and efficient operation of your conveyor system, decreasing downtime and enhancing productivity.

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...