In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

Details

Introduction

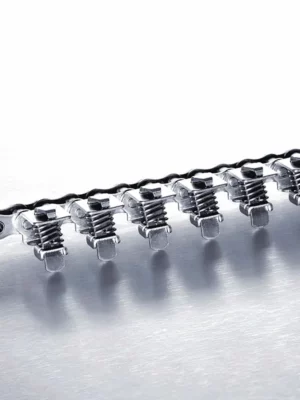

The SSP100A Stainless Steel Metallurgical Anode Copper Conveyor Chain is expertly engineered for metallurgical applications. It boasts outstanding durability, resistance to corrosion, and excellent performance, making it the preferred option for a variety of industrial processes.

1. Superior Material Composition

Constructed from top-quality stainless steel, the SSP100A chain offers remarkable strength and resilience against challenging working conditions. Its high copper content improves conductivity, ensuring the effective flow of electrical current through the chain.

2. Unparalleled Wear Resistance

The SSP100A chain features a state-of-the-art metallurgical anode copper coating that provides exceptional wear resistance. This protective layer safeguards against abrasion, thereby extending the chain’s lifespan and lowering maintenance expenses.

3. Exceptional Corrosion Resistance

With its stainless steel design and specialized coating, the SSP100A chain demonstrates remarkable resistance to corrosion. It can endure exposure to harsh agents like chemicals and elevated temperatures, ensuring enduring performance in demanding environments.

4. Optimal Performance

Engineered for peak performance in metallurgical applications, the SSP100A chain's precise design and high-grade materials minimize friction, enabling smooth and dependable conveyor operation. This chain can support heavy loads and guarantees consistent and efficient material handling.

5. Enhanced Productivity and Efficiency

Utilizing the SSP100A chain allows businesses to achieve greater productivity and efficiency. Its reliable performance and resistance to wear and corrosion decrease downtime and maintenance needs. The chain’s durability contributes to cost savings and improved overall operational effectiveness.

6. Wide Range of Applications

The SSP100A chain's versatility makes it ideal for various applications within the metallurgical sector. It is widely used in conveyor systems for transporting copper and other metal products throughout different production stages, including smelting, refining, and manufacturing.

In summary, the Stainless Steel Metallurgical Anode Copper Conveyor Chain SSP100A stands out for businesses seeking a robust, corrosion-resistant, and high-performance chain for their metallurgical operations. Its excellent material composition, outstanding wear resistance, remarkable corrosion resistance, optimal performance, enhanced productivity and efficiency, and extensive applicability make it a smart investment for industrial uses in the metallurgical field.

Choose Our Stainless Steel Metallurgy Industry Chains

RP Techniek BV serves as the official sales representative of Ever-power Group in the Netherlands, specializing in the production and supply of the high-quality Stainless Steel Metallurgical Anode Copper Conveyor Chain SSP100A. Our chains are specially designed to deliver superior performance and durability. Customers can depend on us for top-tier products paired with exceptional customer service.

Our SSP100A chain is crafted from premium stainless steel, ensuring outstanding corrosion and wear resistance. It is suitable for application in harsh environments, including settings with high temperatures and humidity. Additionally, we provide customization options to meet the specific needs of our clients.

We take pride in our manufacturing capabilities, with an experienced team ensuring that each product adheres to industry standards. Our advanced manufacturing facility is equipped with the latest technology, enabling us to produce high-quality products efficiently.

Beyond the Stainless Steel Metallurgical Anode Copper Conveyor Chain SSP100A, we also offer a wide variety of other stainless steel roller chains. Our products are applicable in several industries, including food and beverage processing, packaging, and pharmaceuticals.

At RP Techniek BV, our commitment lies in providing customers with the highest quality products and exceptional service. Contact us today to discover more about our offerings.

How to Select Suitable Sprockets?

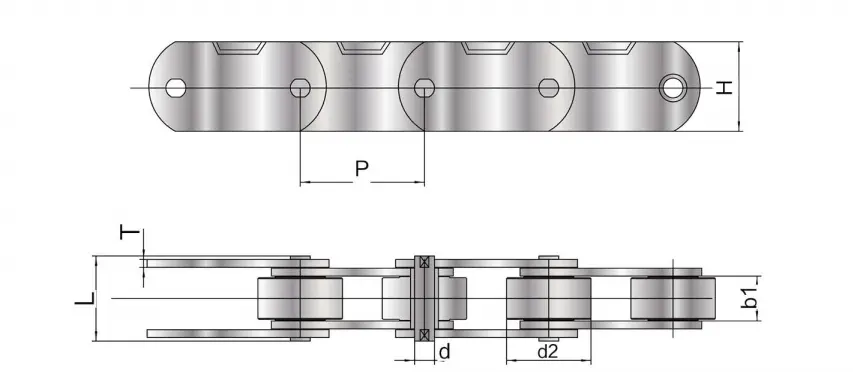

When selecting the right sprockets for the Stainless Steel Metallurgical Anode Copper Conveyor Chain SSP100A, several crucial factors should be considered. Firstly, it is essential to identify the required pitch and tooth count, as these specifications significantly affect the chain's operation and compatibility with the sprockets. The material used for the sprockets should also be chosen carefully to ensure durability and corrosion resistance.

Our company provides a broad selection of sprockets to meet diverse needs. Whether you need standard or custom sprockets, we have the right options for you. Our inventory includes various types, such as single, double, and triple strand sprockets, as well as idler sprockets for tensioning. With our extensive range, finding the ideal sprockets to fulfill your specific requirements is straightforward.

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...