Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

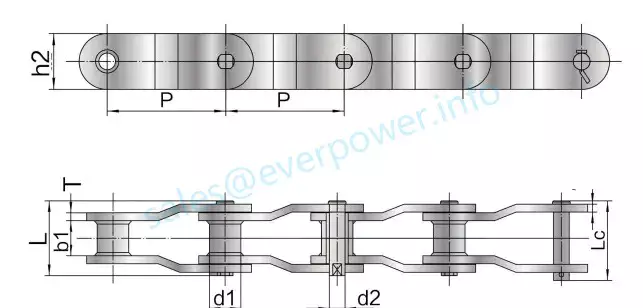

Dimension and Specifications for SSWR150 Stainless Steel Welded Offset Chain

Introduction

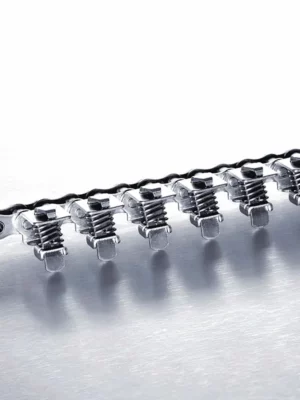

The SSWR150 Stainless Steel Welded Offset Chain is engineered for robustness and high quality, making it suitable for a multitude of applications. Constructed from superior-grade stainless steel, this chain incorporates a welded offset design that ensures remarkable strength and stability under heavy loads. Its compact form and versatile nature make it perfect for various uses, including overhead lifting, material handling, and marine activities. Whether for industrial or marine applications, the SSWR150 stands out as a reliable option.

Advantages of SSWR150 Stainless Steel Welded Offset Chain

- Exceptional durability and corrosion resistance

- Outstanding strength and load capacity

- Precisely engineered for seamless functionality

- Designed to minimize chain elongation

- Requires minimal upkeep

- Applicable across numerous industries and uses

Sprockets for SSWR150 Stainless Steel Welded Offset Chain

We provide an extensive selection of sprockets tailored to work in harmony with the SSWR150 Stainless Steel Welded Offset Chain. These sprockets are meticulously designed to facilitate smooth and efficient operation when paired with the chain. We offer different types of sprockets to meet diverse needs and specifications. Whether you are looking for a standard sprocket or a customized variant, we can meet your requirements. Refer to the image below for an example of our stainless steel sprockets:

Why Choose Our Stainless Steel Welded Chains?

Our SSWR155 Stainless Steel Welded Offset Chain presents significant benefits compared to other chains available. Here’s why:

- Exceptional Strength: Our stainless steel chains boast a strength that can reach 60%-70% of carbon steel, exceeding the typical strength of stainless steel, which is generally only half that of carbon steel.

- Varied Materials: We offer an array of materials, including the 300, 400, and 600 series such as 304, 316L (resistant to strong acids and corrosion), and 310S (withstanding ultra-high temperatures).

- Precise Tolerances: Our chains feature minimal clearances and high precision, ensuring a snug fit.

- High-Quality Chain Plates: Our chain plates undergo a carefully controlled deformation or stress relief treatment during heat processing, ensuring dimensional precision and mechanical integrity. The chain surfaces are also subjected to high-pressure processing for enhanced durability. The thickness of the chain plates is uniform, featuring a bright band from double punching that allows for a snug fit with small pipes and shafts. All holes are centrally located on the chain plates, guaranteeing perfect alignment, and the chain plates maintain excellent flatness.

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...