Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

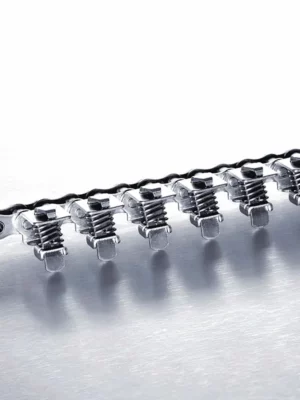

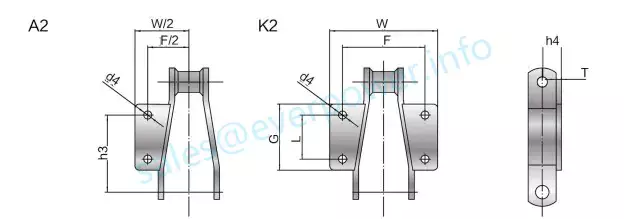

Dimension and Specifications of SSWR132 Stainless Steel Welded Offset Chain with A2 K2 Attachment

Introduction

The SSWR132 Stainless Steel Welded Offset Chain featuring an A2 K2 Attachment is engineered for durability and reliability across various industrial applications. Constructed from premium stainless steel, this chain is highly resistant to corrosion and can endure harsh operating conditions. Its welded offset configuration combined with the A2 K2 attachment delivers exceptional strength and stability, making it a perfect fit for demanding tasks that necessitate precision and accuracy. Whether utilized for lifting, pulling, or securing loads, the SSWR132 Stainless Steel Welded Offset Chain with A2 K2 Attachment ensures dependable performance over many years.

Advantages of SSWR132 Stainless Steel Welded Offset Chain with A2 K2 Attachment

- Exceptional strength and longevity: The SSWR132 Stainless Steel Welded Offset Chain with A2 K2 Attachment is built to handle significant loads and challenging environments, guaranteeing extended performance.

- Resistance to corrosion: Crafted from high-grade stainless steel, this chain is notably resistant to corrosion, making it ideal for harsh conditions and outdoor use.

- Simple maintenance: The stainless steel design facilitates easy cleaning and upkeep, minimizing downtime and enhancing operational efficiency.

- Accurate and dependable functionality: The A2 K2 attachment ensures secure and accurate connection points, promoting smooth and dependable operation across diverse industrial uses.

- Wide applicability: This chain is versatile and can be used in various applications, such as conveyor systems, material handling devices, and industrial machinery.

Sprockets for SSWR132 Stainless Steel Welded Offset Chain with A2 K2 Attachment

For the SSWR132 Stainless Steel Welded Offset Chain with A2 K2 Attachment, we provide an extensive selection of sprockets that enhance its functionality. Our company offers multiple types of sprockets for sale, ensuring you can select the ideal option for your requirements. Whether you need a standard sprocket, a tailored design, or a unique configuration, we are here to assist you.

Why Choose Our Stainless Steel Welded Chains?

Our stainless steel welded chains offer significant advantages that distinguish us from competitors. Firstly, our chains exhibit remarkable strength. Although standard stainless steel typically possesses only half the strength of carbon steel, our chains can attain 60%-70% of the strength associated with carbon steel.

Additionally, we provide an array of materials, including 300, 400, and 600 series, such as 304, 316L (which is resistant to strong acids and corrosion), and 310S (which can withstand extremely high temperatures). Our chains are designed with minimal gaps and high tightness.

A key benefit is our top-tier chain plates. These plates undergo a heat treatment process that regulates deformation or alleviates internal stress through pressure during cooling, thereby ensuring precise dimensions and mechanical properties of the chain. The surface of the chain is treated with high-pressure processing to enhance material durability. The uniform thickness of the chain plates and the double-punching technique create a bright band that ensures tight contact between small tubes and shafts, resulting in high tightness. All holes are precisely centered on the chain plate, maintaining alignment, while the plate exhibits excellent flatness.

Select our stainless steel welded chains for unmatched strength, a diverse range of materials, and superior quality chain plates.

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...