Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

Specifications for SSRF36250 Stainless Steel Conveyor Chain

- Material: Stainless Steel

- Chain Pitch: 38.1mm

- Working Load: 8100N

- Max. Conveyor Length: 12 meters

- Temperature Range: -40¡ãC to 120¡ãC

- Pin Type: Solid Pin

- Sprocket Type: Fabricated

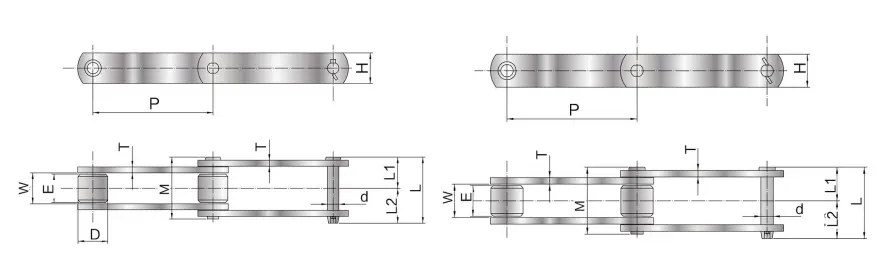

| Chain No. | Roller Type |

Ultimate Tensile Strength |

Pitch | R roller | F roller | S roller | M/N roller | Width Between Inner Plates |

Plate | Pin | Weight Per Meter | Attachment Type | ||||||||||||||||||

| KN | P | D | E | D | K | E | e | Z | D | D | W | H | T | d | L1+L2 | L1 | L2 | R roller (kg/m) |

F roller (kg/m) |

S roller (kg/m) |

M/N roller (kg/m) |

A-1 K-1 |

A-2 K-2 |

Welded A-2 |

Welded A-3 |

SA-2 SK-2 |

G-2 | G-4 | ||

| SSRF03075 | R/F/S | 29 | 75 | 31.8 | 15.5 | 31.8 | 42 | 12 | 1.8 | 4.3 | 15.9 | - | 16.1 | 22 | 3.2 | 8 | 38 | 18 | 20 | 2.7 | 2.8 | 1.9 | - | R/F/S | R/F/S | R/S | ||||

| SSRF03100 | R/F/S | 29 | 100 | 31.8 | 15.5 | 31.8 | 42 | 12 | 1.8 | 4.3 | 15.9 | - | 16.1 | 22 | 3.2 | 8 | 38 | 18 | 20 | 2.3 | 2.4 | 1.7 | - | R/F/S | R/F/S | R/S | ||||

| SSRF430 | R/S | 54 | 101.6 | 38.1 | 19 | - | - | - | - | - | 20.1 | - | 22.8 | 25.4 | 4.8 (5.0) |

9.7 | 55 | 25.5 | 29.5 | 4.3 | 3 | R/S | R/S | R/S | ||||||

| SSRF05075 | S | 69 | 75 | 40 | 19 | 40 | 50 | 14 | 2.5 | 4.5 | 22.2 | - | 22 | 32 | 4.5 | 11.3 | 53.5 | 25 | 28.5 | - | - | 4.2 | - | S | S | |||||

| SSRF05100 | R/F/S | 69 | 100 | 40 | 19 | 40 | 50 | 14 | 2.5 | 4.5 | 22.2 | - | 22 | 32 | 4.5 | 11.3 | 53.5 | 25 | 28.5 | 5 | 5.2 | 3.7 | - | R/F/S | R/F/S | R/S | R/S | |||

| SSRF05150 | R/F/S | 69 | 150 | 40 | 19 | 40 | 50 | 14 | 2.5 | 4.5 | 22.2 | - | 22 | 32 | 4.5 | 11.3 | 53.5 | 25 | 28.5 | 4.1 | 4.1 | 3.2 | - | R/F/S | R/F/S | R/S/M | ||||

| SSRF204 | S | 78 | 66.27 | - | - | - | - | - | - | - | 22.2 | - | 27 | 28.6 | ? 6.3 (6.0) |

11.3 | 65.5 | 31 | 34.5 | - | - | 5.6 | - | S | S | |||||

| SSRF450 | R/F/S/M | 78 | 101.6 | 44.5 | 23 | 44.5 | 55 | 18 | 2.5 | 6.5 | 22.2 | 25.4 | 27 | 28.6 | 6.3(6.0) | 11.3 | 65.5 | 31 | 34.5 | 6.8 | 7.2 | 4.6 | 4.9 | R/F/S/ M |

R/F/S/ M |

R/S/M | ||||

| SSRF08150 | R/F/S/M | 78 | 150 | 44.5 | 23 | 44.5 | 55 | 18 | 2.5 | 6.5 | 22.2 | 25.4 | 27 | 28.6 | ? 6.3 (6.0) |

11.3 | 65.5 | 31 | 34.5 | 5.5 | 5.6 | 4 | 4.2 | R/F/S/ M |

R/F/S/ M |

R/S/M | ||||

| SSRF650 | R/F/S/M | 78 | 152.4 | 50.8 | 26 | 50.8 | 65 | 20 | 3 | 7 | 25.8 | 31.8 | 30.2 | 38.1 | 6.3(6.0) | 11.3 | 69 | 32.5 | 36.5 | 7.7 | 8 | 6 | 6.4 | R/F/S/ M |

R/F/S/ M |

R/S/M | R/S/M | S/M | ||

| SSRF10100 | R/S/M | 113 | 100 | 50.8 | 27 | - | - | - | - | - | 29 | 31.8 | 30 | 38.1 | 6.3 (6.0) |

14.5 | 69 | 33 | 36 | 9.8 | - | 6.8 | 7.1 | R/S/M | R/S/M | R/S/M | ||||

| SSRF10150 | R/F/S/M | 113 | 150 | 50.8 | 27 | 50.8 | 65 | 20 | 3 | 7 | 29 | 31.8 | 30 | 38.1 | 6.3 (6.0) |

14.5 | 69 | 33 | 36 | 79 | 8.1 | 5.9 | 6.1 | R/F/S/ M |

R/F/S M |

R/S/M | R/F/S/ M |

S/M | ||

| SSRF214 | R/S/M | 127 | 101.6 | 44.5 | 27 | - | - | - | - | - | 31.8 | 34.9 | 31.6 | 38.1 | 7.9 | 15.9 | 77.5 | 37.5 | 40 | 10.4 | - | 8.7 | 9.1 | R/S/M | R/S/M | R/S/M | ||||

| SSRF205 | S | 127 | 78.11 | - | - | - | - | - | - | - | 31.8 | - | 37.1 | 38.1 | 7.9 | 15.9 | 83.5 | 40.5 | 43 | - | - | 10.4 | - | S | ||||||

| SSRF6205 | R/F/S/M | 186 | 152.4 | 57.2 | 32 | 57.2 | 70 | 25 | 3.5 | 9 | 34.9 | 38.1 | 37.1 | 44.5 | 7.9 | 15.9 | 83.5 | 40.5 | 43 | 12.1 | 12.4 | 9.3 | 9.6 | R/F/S/ M |

R/F/S M |

R/S/M | R/F/S/ M |

S/M | ||

| SSRF12200 | R/F/S/M | 186 | 200 | 65 | 32 | 65 | 80 | 24 | 4 | 8 | 34.9 | 38.1 | 37.1 | 44.5 | 7.9 | 15.9 | 83.5 | 40.5 | 43 | 11.4 | 11.9 | 8.4 | 8.7 | R/F/S/ M |

R/F/S/ M |

R/S/M | R/F/S/ M |

S/M | ||

| SSRF12250 | R/F/S/M | 186 | 250 | 65 | 32 | 65 | 80 | 24 | 4 | 8 | 34.9 | 38.1 | 37.1 | 44.5 | 7.9 | 15.9 | 83.5 | 40.5 | 43 | 10.3 | 10.6 | 7.8 | 8 | R/F/S/ M |

R/F/S/ M |

R/S/M | R/F/S/ M |

S/M | ||

| SSRF212 | R/S/M | 245 | 152.4 | 69.9 | 32.5 | - | - | - | - | - | 40.1 | 44.4 | 37.1 | 50.8 | 9.5(10.0) | 19.1 | 95.5 | 44.5 | 51 | 17.1 | - | 12.6 | 13.1 | R/S/M | R/S/M | R/S/M | ||||

| SSRF17200 | R/F/S/M | 245 | 200 | 80 | 44 | 80 | 100 | 34 | 5 | 12 | 40.1 | 44.5 | 51.4 | 50.8 | 9.5(10.0) | 19.1 | 109.5 | 51.5 | 58 | 18.8 | 19.8 | 12.3 | 12.6 | R/F/S/ M |

R/F/S/ M |

|||||

| Editor | Zqq |

|---|

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...