Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

Specifications

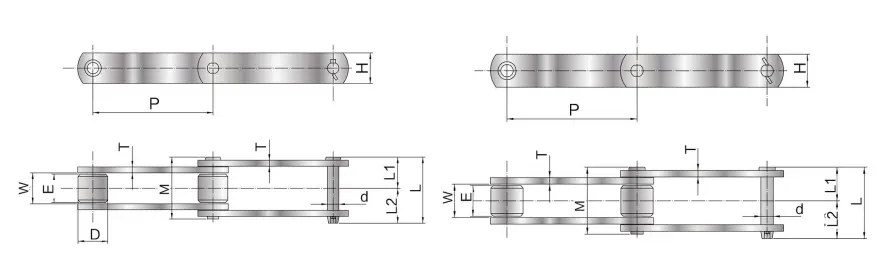

The SSRF08150 Stainless Steel Conveyor Chain has the following parameters:

- Material: Stainless Steel

- Model: SSRF08150

- Type: Conveyor Chain

| Chain No. | Roller Type |

Ultimate Tensile Strength |

Pitch | R roller | F roller | S roller | M/N roller | Width Between Inner Plates |

Plate | Pin | Weight Per Meter | Attachment Type | |||||||||||||||||||||||||||||

| KN | P | D | E | D | K | E | e | Z | D | D | W | H | T | d | L1+L2 | L1 | L2 | R roller (kg/m) |

F roller (kg/m) |

S roller (kg/m) |

M/N roller (kg/m) |

A-1 K-1 |

A-2 K-2 |

Welded A-2 |

Welded A-3 |

SA-2 SK-2 |

G-2 | G-4 | |||||||||||||

| SSRF03075 | R/F/S | 29 | 75 | 31.8 | 15.5 | 31.8 | 42 | 12 | 1.8 | 4.3 | 15.9 | - | 16.1 | 22 | 3.2 | 8 | 38 | 18 | 20 | 2.7 | 2.8 | 1.9 | - | R/F/S | R/F/S | R/S | |||||||||||||||

| SSRF03100 | R/F/S | 29 | 100 | 31.8 | 15.5 | 31.8 | 42 | 12 | 1.8 | 4.3 | 15.9 | - | 16.1 | 22 | 3.2 | 8 | 38 | 18 | 20 | 2.3 | 2.4 | 1.7 | - | R/F/S | R/F/S | R/S | |||||||||||||||

| SSRF430 | R/S | 54 | 101.6 | 38.1 | 19 | - | - | - | - | - | 20.1 | - | 22.8 | 25.4 | 4.8 (5.0) |

9.7 | 55 | 25.5 | 29.5 | 4.3 | 3 | R/S | R/S | R/S | |||||||||||||||||

| SSRF05075 | S | 69 | 75 | 40 | 19 | 40 | 50 | 14 | 2.5 | 4.5 | 22.2 | - | 22 | 32 | 4.5 | 11.3 | 53.5 | 25 | 28.5 | - | - | 4.2 | - | S | S | ||||||||||||||||

| SSRF05100 | R/F/S | 69 | 100 | 40 | 19 | 40 | 50 | 14 | 2.5 | 4.5 | 22.2 | - | 22 | 32 | 4.5 | 11.3 | 53.5 | 25 | 28.5 | 5 | 5.2 | 3.7 | - | R/F/S | R/F/S | R/S | R/S | ||||||||||||||

| SSRF05150 | R/F/S | 69 | 150 | 40 | 19 | 40 | 50 | 14 | 2.5 | 4.5 | 22.2 | - | 22 | 32 | 4.5 | 11.3 | 53.5 | 25 | 28.5 | 4.1 | 4.1 | 3.2 | - | R/F/S | R/F/S | R/S/M | |||||||||||||||

| SSRF204 | S | 78 | 66.27 | - | - | - | - | - | - | - | 22.2 | - | 27 | 28.6 | ? 6.3 (6.0) |

11.3 | 65.5 | 31 | 34.5 | - | - | 5.6 | - | S | S | ||||||||||||||||

| SSRF450 | R/F/S/M | 78 | 101.6 | 44.5 | 23 | 44.5 | 55 | 18 | 2.5 | 6.5 | 22.2 | 25.4 | 27 | 28.6 | 6.3(6.0) | 11.3 | 65.5 | 31 | 34.5 | 6.8 | 7.2 | 4.6 | 4.9 | R/F/S/ M |

R/F/S/ M |

R/S/M | |||||||||||||||

| SSRF08150 | R/F/S/M | 78 | 150 | 44.5 | 23 | 44.5 | 55 | 18 | 2.5 | 6.5 | 22.2 | 25.4 | 27 | 28.6 | ? 6.3 (6.0) |

11.3 | 65.5 | 31 | 34.5 | 5.5 | 5.6 | 4 | 4.2 | R/F/S/ M |

R/F/S/ M |

R/S/M | |||||||||||||||

| SSRF650 | R/F/S/M | 78 | 152.4 | 50.8 | 26 | 50.8 | 65 | 20 | 3 | 7 | 25.8 | 31.8 | 30.2 | 38.1 | 6.3(6.0) | 11.3 | 69 | 32.5 | 36.5 | 7.7 | 8 | 6 | 6.4 | R/F/S/ M |

R/F/S/ M |

R/S/M | R/S/M | S/M | |||||||||||||

| SSRF10100 | R/S/M | 113 | 100 | 50.8 | 27 | - | - | - | - | - | 29 | 31.8 | 30 | 38.1 | 6.3 (6.0) |

14.5 | 69 | 33 | 36 | 9.8 | - | 6.8 | 7.1 | R/S/M | R/S/M | R/S/M | |||||||||||||||

| SSRF10150 | R/F/S/M | 113 | 150 | 50.8 | 27 | 50.8 | 65 | 20 | 3 | 7 | 29 | 31.8 | 30 | 38.1 | 6.3 (6.0) |

14.5 | 69 | 33 | 36 | 79 | 8.1 | 5.9 | 6.1 | R/F/S/ M |

R/F/S M |

R/S/M | R/F/S/ M |

S/M | |||||||||||||

| SSRF214 | R/S/M | 127 | 101.6 | 44.5 | 27 | - | - | - | - | - | 31.8 | 34.9 | 31.6 | 38.1 | 7.9 | 15.9 | 77.5 | 37.5 | 40 | 10.4 | - | 8.7 | 9.1 | R/S/M | R/S/M | R/S/M | |||||||||||||||

| SSRF205 | S | 127 | 78.11 | - | - | - | - | - | - | - | 31.8 | - | 37.1 | 38.1 | 7.9 | 15.9 | 83.5 | 40.5 | 43 | - | - | 10.4 | - | S | |||||||||||||||||

| SSRF6205 | R/F/S/M | 186 | 152.4 | 57.2 | 32 | 57.2 | 70 | 25 | 3.5 | 9 | 34.9 | 38.1 | 37.1 | 44.5 | 7.9 | 15.9 | 83.5 | 40.5 | 43 | 12.1 | 12.4 | 9.3 | 9.6 | R/F/S/ M |

R/F/S M |

R/S/M | R/F/S/ M |

S/M | |||||||||||||

| SSRF12200 | R/F/S/M | 186 | 200 | 65 | 32 | 65 | 80 | 24 | 4 | 8 | 34.9 | 38.1 | 37.1 | 44.5 | 7.9 | 15.9 | 83.5 | 40.5 | 43 | 11.4 | 11.9 | 8.4 | 8.7 | R/F/S/ M |

R/F/S/ M |

R/S/M | R/F/S/ M |

S/M | |||||||||||||

| SSRF12250 | R/F/S/M | 186 | 250 | 65 | 32 | 65 | 80 | 24 | 4 | 8 | 34.9 | 38.1 | 37.1 | 44.5 | 7.9 | 15.9 | 83.5 | 40.5 | 43 | 10.3 | 10.6 | 7.8 | 8 | R/F/S/ M |

R/F/S/ M |

R/S/M | R/F/S/ M |

S/M | |||||||||||||

| SSRF212 | R/S/M | 245 | 152.4 | 69.9 | 32.5 | - | - | - | - | - | 40.1 | 44.4 | 37.1 | 50.8 | 9.5(10.0) | 19.1 | 95.5 | 44.5 | 51 | 17.1 | - | 12.6 | 13.1 | R/S/M | R/S/M | R/S/M | |||||||||||||||

| SSRF17200 | R/F/S/M | 245 | 200 | 80 | 44 | 80 | 100 | 34 | 5 | 12 | 40.1 | 44.5 | 51.4 | 50.8 | 9.5(10.0) | 19.1 | 109.5 | 51.5 | 58 | 18.8 | 19.8 | 12.3 | 12.6 | R/F/S/ M |

R/F/S/ M |

||||||||||||||||

| Chain Type | SSRF08150 Stainless Steel Conveyor Chain |

|---|---|

| Material | Stainless Steel |

| Pitch | 8.00mm |

| Width | 15.00mm |

| Pin Diameter | 3.20mm |

| Breaking Load | 7500N |

Title 5: Maintenance and Care

Proper maintenance and care can ensure the longevity and optimal performance of the SSRF08150 Stainless Steel Conveyor Chain. Here are some maintenance tips:

- Regularly inspect for any signs of wear, damage, or elongation.

- Keep the chain clean and free from debris or contaminants.

- Apply appropriate lubrication to minimize friction and wear.

- Follow manufacturer guidelines for tension adjustment.

By following these maintenance practices, you can maximize the lifespan and efficiency of the SSRF08150 Stainless Steel Conveyor Chain, reducing downtime and improving productivity.

Why Choose Our Stainless Steel Roller Chains?

RP Techniek BV is the Netherlands sales representative of Ever-power Group. We take pride in being associated with a renowned global brand known for its excellence in the industry.

Our SSRF08150 Stainless Steel Conveyor Chain is a testament to our commitment to delivering high-quality products. Made from durable stainless steel, this roller chain is designed to withstand demanding conditions and provide reliable performance.

What sets us apart is not just our exceptional products but also our outstanding service. We prioritize customer satisfaction and strive to exceed expectations at every step. From initial inquiry to after-sales support, our dedicated team is always ready to assist you.

With our robust manufacturing capabilities and advanced technology, we ensure consistent quality and precision in every stainless steel roller chain we produce. Our state-of-the-art facilities and skilled workforce enable us to meet the diverse needs of our customers with efficiency and expertise.

In addition to the SSRF08150 Stainless Steel Conveyor Chain, we offer a wide range of other stainless steel roller chains for various applications. Whether you require chains for industrial machinery, food processing equipment, or any other specific requirements, we have you covered.

Trust in our expertise and experience to deliver top-notch stainless steel roller chains that meet your needs. Contact us today to discuss your requirements and experience the difference of choosing RP Techniek BV as your trusted partner.

Sprockets for Sale

If you're in the market for a reliable and durable conveyor chain, the SSRF08150 Stainless Steel Conveyor Chain is a great choice. This chain is made from high-quality stainless steel, making it resistant to corrosion and wear, and is designed to provide a smooth and efficient conveying experience.

To complement the SSRF08150 chain, we offer a wide range of sprockets that are compatible with this chain. Our sprockets are made from top-grade materials and are designed to provide a perfect fit with the SSRF08150 chain, ensuring optimal performance and longevity. Our selection of sprockets includes various sizes, tooth counts, and pitch configurations, making it easy to find the right sprocket to match your needs.

At our company, we take pride in providing our customers with high-quality conveyor chain and sprockets at competitive prices. We offer a variety of different types of sprockets, including finished bore, taper bore, and pilot bore sprockets, to ensure that we have the right product for any application. Additionally, we offer custom sprockets to meet any unique specification or requirement.

If you're in need of sprockets for your conveyor system, look no further than our company. Contact us today to discuss your needs and find the perfect solution for your application.

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...