In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

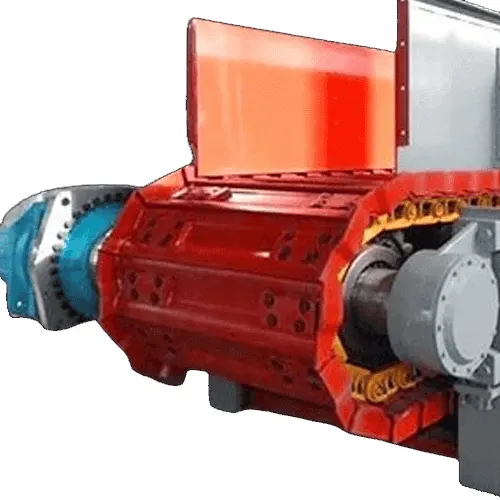

Specialized Chain for Nonferrous Metals Melting Industry

Specialized chains are essential within the nonferrous metals melting industry due to their superior heat resistance, effective corrosion protection, substantial load capacity, minimal maintenance needs, and personalization options. With their outstanding performance and reliability, these chains facilitate efficient and successful melting operations, contributing to the production of high-quality nonferrous metals.

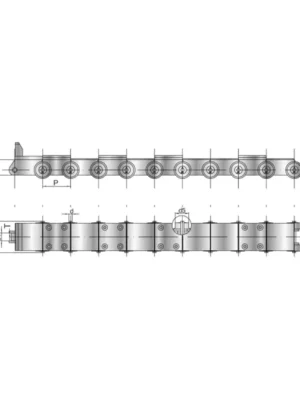

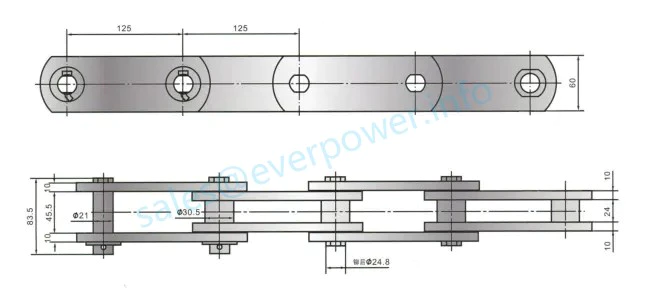

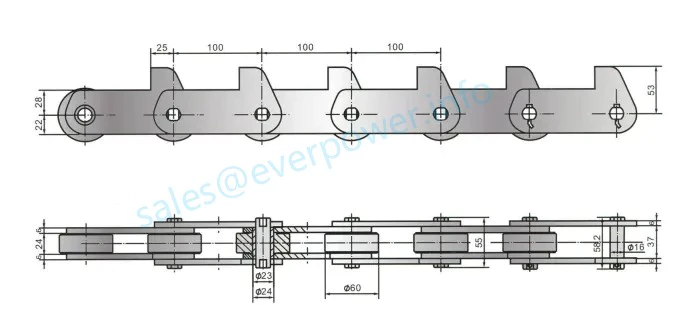

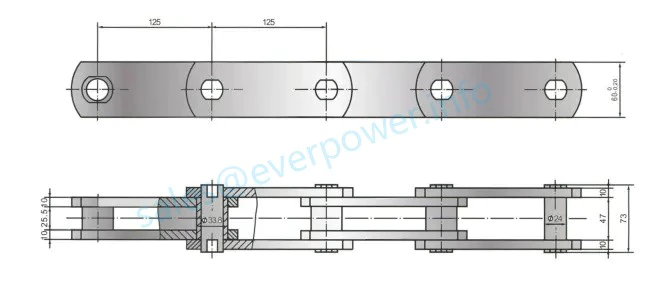

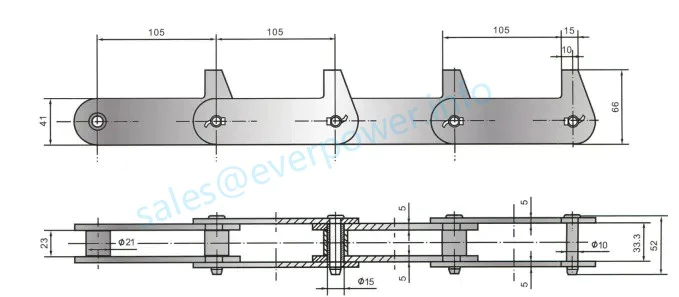

Dimensions of Specialized Chain for Nonferrous Metals Melting Industry

Below are the specifications of these chains:

Stainless Steel Plate Washing Chain

Stainless Steel Water Tank Chain

Stainless Steel Guide Chain

Stainless Steel Chain

Plate Feeding Machine Chain

Stainless Steel Washing Chain

In the realm of nonferrous metals melting, specialized chains are vital for promoting efficient and dependable operations. These chains are specifically crafted to endure high temperatures, corrosive conditions, and substantial loads, making them crucial components in the melting process. Their distinctive characteristics and remarkable performance make specialized chains the preferred option for melting applications involving nonferrous metals.

Superior Heat Resistance

A significant benefit of specialized chains in the nonferrous metals melting sector is their exceptional heat resistance. These chains are meticulously designed to endure extreme temperatures, ensuring optimal functionality even in the hottest settings. The advanced materials used in their construction allow them to retain their strength and structural integrity, delivering dependable operation throughout the melting process.

Corrosion Protection

Amidst the highly corrosive environments of nonferrous metals melting, these chains face constant exposure to harsh chemicals and aggressive substances. Specialized chains are equipped with a robust corrosion protection mechanism that safeguards them from deterioration and enhances their longevity. The innovative coating technologies and corrosion-resistant materials incorporated during manufacturing provide remarkable resistance to corrosive elements, ensuring consistent performance in challenging conditions.

High Load Capacity

Operations in the nonferrous metals melting industry require managing heavy loads and substantial mechanical forces. Specialized chains are built to withstand these rigorous conditions with their impressive load capacity. Constructed from high-strength materials, these chains incorporate advanced design aspects, such as reinforced links and specialized load-bearing components, which enable them to sustain the extreme loads experienced during the melting process, ensuring safe and effective operation.

Low Maintenance Requirements

To reduce downtime and maximize productivity, specialized chains designed for the nonferrous metals melting industry are built with low maintenance needs. The use of high-quality materials and precise manufacturing techniques minimizes the necessity for frequent lubrication and adjustments. Moreover, the chains' sturdy construction and resilient components enhance their longevity, decreasing the frequency of replacements and resulting in cost efficiency for operators.

Customization Options

Specialized chains provide various customization options to cater to the specific demands of nonferrous metals melting applications. Manufacturers offer an array of chain sizes, configurations, and accessories to ensure compatibility with diverse equipment and processes. Customization options also encompass specialized coatings, added protection against specific chemicals, and bespoke designs for unique operational scenarios. This adaptability enables operators to fine-tune their processes and achieve enhanced performance in nonferrous metals melting.

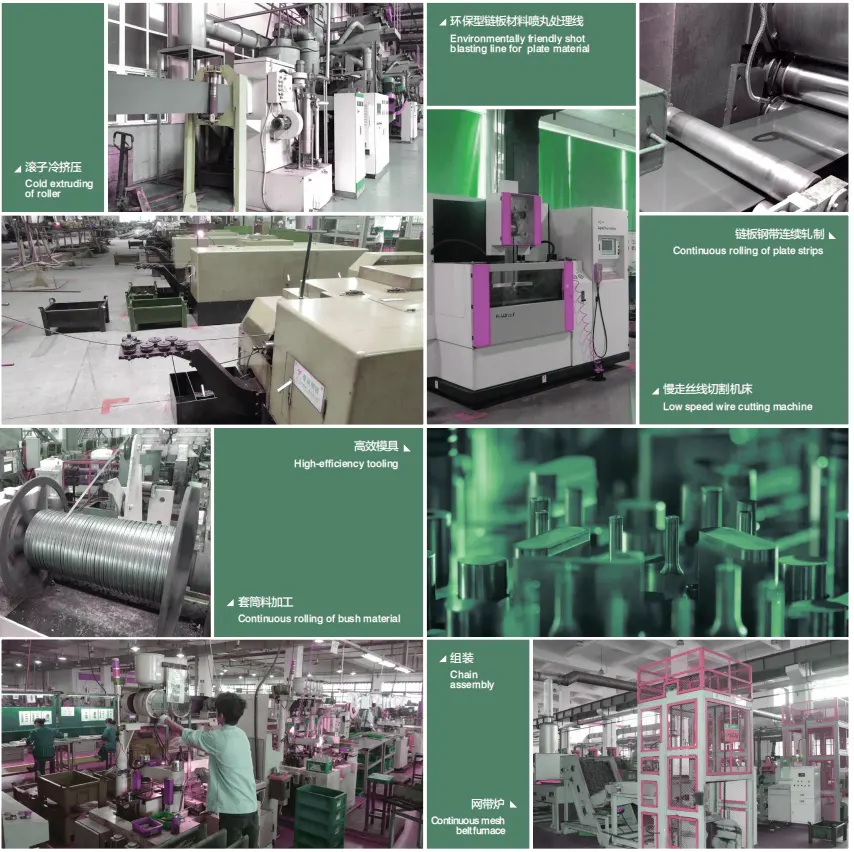

Why Choose Our Stainless Steel Roller Chains?

RP Techniek BV serves as the authorized sales representative for Ever-power Group in the Netherlands. We take pride in providing specialized chain solutions tailored for the nonferrous metals melting industry. Our unique selling propositions hinge on our product quality, exceptional service, and robust manufacturing capabilities.

Our stainless steel roller chains are designed to meet the stringent demands of the nonferrous metals melting industry. Built for superior strength and durability, they guarantee smooth and dependable operation even in the most challenging environments. Each chain is meticulously crafted to ensure optimal performance and maximum efficiency, reducing downtime and boosting productivity.

In addition to our specialized chains for the nonferrous metals melting sector, we offer an extensive range of other stainless steel roller chains. Whether you require chains for food processing, pharmaceuticals, or any other sector that demands corrosion-resistant and high-performance chains, we have the solution for you.

At RP Techniek BV, we are dedicated to delivering top-quality stainless steel roller chains and unmatched service to our customers. With our vast experience and expertise, we are committed to fulfilling your specific requirements and surpassing your expectations.

Sprockets for Sale

When searching for the appropriate chain for your nonferrous metals melting operations, it’s essential to have the right sprockets to ensure everything functions smoothly. Our company offers a selection of sprockets specifically engineered to pair with specialized chains in this industry.

Our sprockets are crafted from high-quality materials and come in various sizes to cater to your specific requirements. We recognize that each industry has unique needs, which is why we provide a wide assortment of sprocket types to choose from.

Whether you need a standard sprocket or a more specialized variant, our company has you covered. We take pride in supplying top-notch sprockets at competitive prices, ensuring you receive the best value for your investment.

Feel free to reach out to us with any questions or to place an order. Our team of experts is always ready to assist you.

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...