In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

Specifications of RF2050-GRSS Stainless Steel Conveyor Chain with Side Rollers

- Chain Pitch: RF2050

- Material: Stainless Steel

- Roller Type: Side Rollers

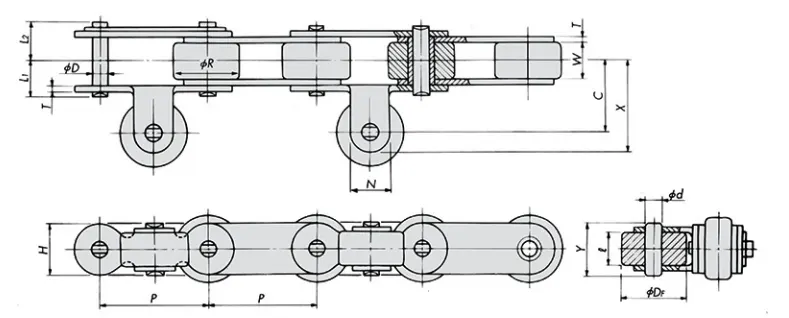

| Chain No. | P | W | S | R | D | L1????? L2 | H | T | C | X | N | Y | d | DF | |

| RF2040-GRSS | 25.4 | 7.95 | 7.92 | 15.88 | 3.97 | 8.25?? 9.95 | 12 | 1.5 | 17.45 | 22.2 | 9.5 | 13.2 | 3.97 | 15.88 | 7.8 |

| RF2050-GRSS | 31.75 | 9.53 | 10.16 | 19.05 | 5.09 | 10.30 12.00 | 15 | 2 | 21.15 | 27.5 | 12.7 | 16.2 | 5.09 | 19.05 | 9.4 |

| RF2060-GRSS | 38.1 | 12.7 | 11.91 | 22.23 | 5.96 | 14.55 16.55 | 17.2 | 3.2 | 27 | 34.95 | 15.9 | 22.2 | 5.96 | 22.23 | 12.6 |

| RF2080-GRSS | 50.8 | 15.88 | 15.88 | 28.58 | 7.94 | 18.3?? 20.9 | 23 | 4 | 33.35 | 42.9 | 19.1 | 27.4 | 7.94 | 28.58 | 15.8 |

| RF2100-GRSS | 63.5 | 19.05 | 19.05 | 39.69 | 9.54 | 21.8?? 24.5 | 28.6 | 4.8 | 42.85 | 55.55 | 25.4 | 32.7 | 9.54 | 39.69 | 19 |

Introduction

The RF2050-GRSS Stainless Steel Conveyor Chain featuring Side Rollers is a premium conveyor chain utilized across various industries. Engineered for durability in challenging environments, this chain is crafted from high-grade stainless steel, offering resistance to both corrosion and wear. The inclusion of side rollers aids in minimizing friction and abrasion on the chain, thereby enhancing its lifespan and lowering maintenance expenses.

Features

- Constructed from high-grade stainless steel

- Side rollers designed to decrease friction and wear

- Resistant to corrosion

- Designed for longevity

- Ideal for operation in demanding environments

Applications

The RF2050-GRSS Stainless Steel Conveyor Chain with Side Rollers is versatile and fits a broad spectrum of industries, including:

- Food processing

- Beverage production

- Pharmaceutical manufacturing

- Chemical processing

- Packaging and labeling

Technical Specifications

The RF2050-GRSS Stainless Steel Conveyor Chain with Side Rollers comes with the following technical specifications:

- Chain pitch: 50.8mm

- Roller diameter: 25.4mm

- Chain width: 152.4mm

- Overall width: 187.9mm

- Breaking load: 85.5kN

- Weight per meter: 12.9kg

Installation and Maintenance

For optimal performance, proper installation and maintenance of the RF2050-GRSS Stainless Steel Conveyor Chain with Side Rollers are crucial. It is recommended that a qualified professional perform the installation. Regular cleaning and lubrication are necessary to minimize wear and prolong the chain's lifespan. Periodic inspections should be conducted to check for signs of damage or wear, with any compromised parts replaced promptly to avert further issues.

Conclusion

The RF2050-GRSS Stainless Steel Conveyor Chain with Side Rollers is an exceptional conveyor solution designed for enduring performance in tough conditions. With its robust stainless steel build, side rollers that mitigate friction and wear, and its corrosion-resistant nature, it is well-suited for a diverse range of industries. Adhering to proper installation and maintenance techniques is essential for maximizing its durability and reducing upkeep costs.

Choose Our Stainless Steel Roller Chains

RP Techniek BV, representing Ever-power Group in the Netherlands, proudly offers the RF2050-GRSS Stainless Steel Conveyor Chain with Side Rollers. Our company stands out with its exceptional product quality, excellent customer service, and strong manufacturing capabilities. We focus on providing high-quality stainless steel roller chains tailored to your business needs.

At RP Techniek BV, we have a wide assortment of other stainless steel roller chains available. Our comprehensive selection ensures that you will find the ideal chain for your specific requirements. With our varied options, you can trust us to deliver the best solution for your industrial applications.

Sprockets for Sale

If you're searching for the perfect complement to the RF2050-GRSS Stainless Steel Conveyor Chain with Side Rollers, our extensive range of sprockets is your answer. Our company provides a variety of sprockets tailored to meet your unique requirements.

Our sprockets are designed with precision and built for durability. Whether you need a standard or custom sprocket, we can accommodate your needs. Our vast inventory includes sprockets of various sizes, materials, and tooth configurations, ensuring you find the perfect fit for your application.

With our top-quality sprockets, you can anticipate reliable performance and a longer service life. Recognizing the importance of a smooth and efficient conveyor system, we offer sprockets engineered to endure heavy loads and challenging operational conditions.

Check out the image below for a sneak peek of our sprocket collection:

Whether you need a single sprocket or a bulk order, our team is ready to assist you. Reach out to us today to discuss your sprocket needs and place your order.

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...