Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

Specifications

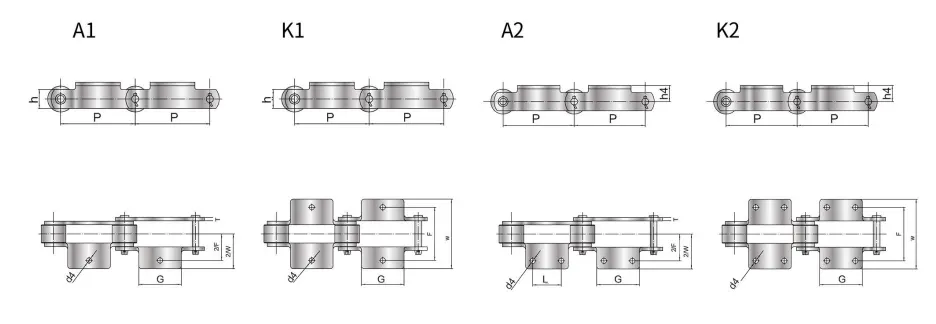

The RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF430 has the following parameters:

| Chain No. | Roller Type | Pitch (P) |

h4 | 2/F | F | 2W | W | L | T | d4 | Bolt Dimension |

Weight of SA2 att.(KG) |

|

| RF0375 | R/F/S | 75 | 20 | 30 | 60 | 46 | 92 | 30 | 55 | 3.2 | 10 | M8 | 0.05 |

| RF03100 | R/F/S | 100 | 20 | 30 | 60 | 46 | 92 | 40 | 65 | 3.2 | 10 | M8 | 0.06 |

| RF430 | R/S | 101.6 | 22 | 40 | 80 | 54 | 108 | 40 | 70 | 4.8(5.0) | 12 | M10 | 0.11 |

| RF05075 | S | 75 | 22 | 35 | 70 | 47 | 94 | 30 | 55 | 4.5 | 10 | M8 | 0.07 |

| RF05100 | R/F/S | 100 | 22 | 35 | 70 | 47 | 94 | 40 | 65 | 4.5 | 10 | M8 | 0.08 |

| RF05150 | R/F/S | 150 | 22 | 35 | 70 | 47 | 94 | 60 | 85 | 4.5 | 10 | M8 | 0.1 |

| RF204 | S | 66.27 | 24 | 45 | 90 | 59 | 118 | - | 35 | 6.3(6.0) | 12 | M10 | 0.08 |

| RF450 | R/F/S/M | 101.6 | 28 | 50 | 100 | 64 | 128 | 40 | 70 | 6.3(6.0) | 12 | M10 | 0.18 |

| RF08150 | R/F/S/M | 150 | 28 | 50 | 100 | 64 | 128 | 60 | 90 | 6.3(6.0) | 12 | M10 | 0.22 |

| RF650 | R/F/S/M | 152.4 | 32 | 50 | 100 | 64 | 128 | 60 | 90 | 6.3(6.0) | 12 | M10 | 0.22 |

| RF10100 | R/S/M | 100 | 28 | 50 | 100 | 65 | 130 | 40 | 70 | 6.3(6.0) | 12 | M10 | 0.16 |

| RF10150 | R/F/S/M | 150 | 28 | 50 | 100 | 65 | 130 | 60 | 90 | 6.3(6.0) | 12 | M10 | 0.2 |

| RF214 | R/S/M | 101.6 | 35 | 55 | 110 | 73 | 146 | 40 | 80 | 7.9 | 15 | M12 | 0.28 |

| RF205 | S | 78.11 | 35 | 60 | 120 | 75 | 150 | 30 | 65 | 7.9 | 12 | M10 | 0.23 |

| RF6205 | R/F/S/M | 152.4 | 38 | 60 | 120 | 79 | 158 | 60 | 100 | 7.9 | 15 | M12 | 0.37 |

| RF12200 | R/F/S/M | 200 | 38 | 60 | 120 | 79 | 158 | 80 | 120 | 7.9 | 15 | M12 | 0.45 |

| RF12250 | R/F/S/M | 250 | 38 | 60 | 120 | 79 | 158 | 125 | 170 | 7.9 | 15 | M12 | 0.62 |

| RF212 | R/S/M | 152.4 | 45 | 65 | 130 | 83 | 166 | 60 | 100 | 9.5(10.0) | 15 | M12 | 0.49 |

| RF17200 | R/F/S/M | 200 | 45 | 75 | 150 | 98 | 196 | 80 | 120 | 9.5(10.0) | 15 | M12 | 0.66 |

| RF17250 | R/F/S/M | 250 | 45 | 75 | 150 | 98 | 125 | 125 | 170 | 9.5(10.0) | 15 | M12 | 0.86 |

Title 1: Introduction to RF Type Conveyor Chain

The RF Type Conveyor Chain is a highly durable and efficient conveyor chain that is widely used in various industrial applications. With its advanced design and high-quality materials, it offers exceptional performance and reliability in conveying heavy loads.

Title 2: Overview of A1 K1 A2 K2 Attachment

The A1 K1 A2 K2 attachment is a special feature of the RF Type Conveyor Chain that allows for precise and secure attachment of additional components or accessories. It provides flexibility in customizing the conveyor chain according to specific requirements, making it suitable for a wide range of applications.

Title 3: Features and Benefits of RF430

The RF430, a specific variant of the RF Type Conveyor Chain, offers several unique features and benefits:

- 1. Superior Load Capacity: The RF430 has been specially designed to handle heavy loads with ease, ensuring smooth and efficient operation.

- 2. Enhanced Durability: Constructed with high-quality materials, the RF430 exhibits exceptional strength and durability, minimizing the need for frequent maintenance and replacement.

- 3. Precise Attachment: The A1 K1 A2 K2 attachment of the RF430 allows for precise and secure attachment of accessories, ensuring reliable performance in demanding applications.

- 4. Smooth Operation: The RF430 incorporates advanced engineering techniques that reduce friction and noise, resulting in quiet and efficient operation.

- 5. Versatile Application: With its robust design and customizable features, the RF430 is suitable for a wide range of industries, including automotive, food processing, and warehousing.

Title 4: Applications

The RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF430 finds extensive use in various industries, including:

- 1. Automotive: The RF430 is ideal for automotive assembly lines, where it ensures smooth and reliable transportation of heavy components.

- 2. Food Processing: In the food processing industry, the RF430 facilitates the efficient movement of packaged goods, ensuring a streamlined production process.

- 3. Warehousing: The RF430 is widely employed in warehouses for handling and conveying bulky items, improving overall operational efficiency.

Title 5: Maintenance and Care

To maximize the lifespan and performance of the RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF430, it is important to follow these maintenance guidelines:

- 1. Regular Lubrication: Apply a suitable lubricant to the chain at specified intervals to minimize friction and prevent premature wear.

- 2. Inspection: Regularly inspect the chain for signs of damage or wear. Replace any worn-out components promptly to avoid operational disruptions.

- 3. Cleaning: Keep the chain clean by removing any debris or contaminants that may hinder its smooth operation.

- 4. Proper Tension: Ensure the chain has the correct tension to prevent slippage and maintain efficient operation.

- 5. Professional Assistance: In case of any issues or complex maintenance requirements, consult a qualified professional for assistance.

Why Choose Our Stainless Steel Roller Chains?

RP Techniek BV, the Netherlands sales agent for Ever-power Group, is proud to offer high-quality stainless steel roller chains. Our exclusive RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF430 sets us apart from the competition.

Our stainless steel roller chains are known for their exceptional durability and reliability. With superior engineering and precise manufacturing, our chains are designed to withstand heavy loads and harsh environments. You can trust our chains to deliver outstanding performance and longevity.

In addition to our RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF430, we also offer a wide range of other stainless steel roller chains. Whatever your specific needs may be, we have the right chain for you. Whether it's for agricultural, industrial, or other applications, our chains are designed to meet the highest standards.

At RP Techniek BV, we take pride in our production capabilities. Our state-of-the-art facilities and experienced team ensure that every stainless steel roller chain we produce meets the strictest quality standards. With our commitment to excellence, you can trust that you are getting the best product available.

Please see the attached image below to get a visual representation of our stainless steel roller chains:

Sprockets for Sale

When it comes to the RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF430, finding the perfect matching sprockets is crucial. At our company, we offer a wide range of different types of sprockets to meet your needs.

Our selection includes sprockets made from high-quality materials, ensuring durability and reliable performance. Whether you require standard sprockets or custom-made options, we have got you covered.

With our extensive inventory, we can provide the ideal sprockets to complement the RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF430. Our sprockets are designed with precision to ensure smooth and efficient operation, reducing wear and extending chain life.

By choosing our sprockets, you are investing in top-notch quality and reliability. Our team of experts is dedicated to delivering products that exceed your expectations.

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...