Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

Specifications

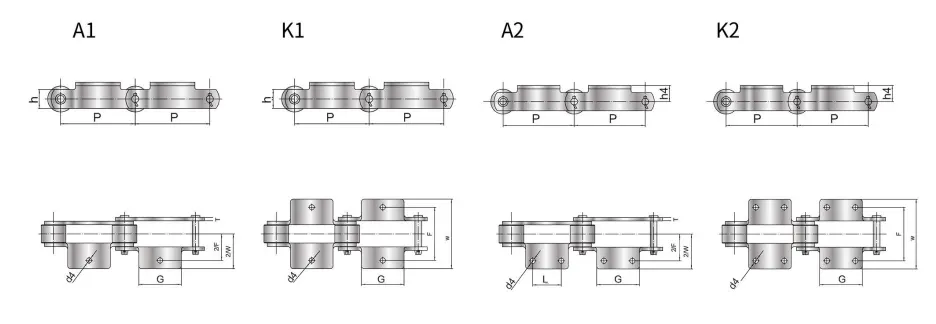

The RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF17250 has the following parameters:

| Chain No. | Roller Type | Pitch (P) |

h4 | 2/F | F | 2W | W | L | T | d4 | Bolt Dimension |

Weight of SA2 att.(KG) |

|

| RF0375 | R/F/S | 75 | 20 | 30 | 60 | 46 | 92 | 30 | 55 | 3.2 | 10 | M8 | 0.05 |

| RF03100 | R/F/S | 100 | 20 | 30 | 60 | 46 | 92 | 40 | 65 | 3.2 | 10 | M8 | 0.06 |

| RF430 | R/S | 101.6 | 22 | 40 | 80 | 54 | 108 | 40 | 70 | 4.8(5.0) | 12 | M10 | 0.11 |

| RF05075 | S | 75 | 22 | 35 | 70 | 47 | 94 | 30 | 55 | 4.5 | 10 | M8 | 0.07 |

| RF05100 | R/F/S | 100 | 22 | 35 | 70 | 47 | 94 | 40 | 65 | 4.5 | 10 | M8 | 0.08 |

| RF05150 | R/F/S | 150 | 22 | 35 | 70 | 47 | 94 | 60 | 85 | 4.5 | 10 | M8 | 0.1 |

| RF204 | S | 66.27 | 24 | 45 | 90 | 59 | 118 | - | 35 | 6.3(6.0) | 12 | M10 | 0.08 |

| RF450 | R/F/S/M | 101.6 | 28 | 50 | 100 | 64 | 128 | 40 | 70 | 6.3(6.0) | 12 | M10 | 0.18 |

| RF08150 | R/F/S/M | 150 | 28 | 50 | 100 | 64 | 128 | 60 | 90 | 6.3(6.0) | 12 | M10 | 0.22 |

| RF650 | R/F/S/M | 152.4 | 32 | 50 | 100 | 64 | 128 | 60 | 90 | 6.3(6.0) | 12 | M10 | 0.22 |

| RF10100 | R/S/M | 100 | 28 | 50 | 100 | 65 | 130 | 40 | 70 | 6.3(6.0) | 12 | M10 | 0.16 |

| RF10150 | R/F/S/M | 150 | 28 | 50 | 100 | 65 | 130 | 60 | 90 | 6.3(6.0) | 12 | M10 | 0.2 |

| RF214 | R/S/M | 101.6 | 35 | 55 | 110 | 73 | 146 | 40 | 80 | 7.9 | 15 | M12 | 0.28 |

| RF205 | S | 78.11 | 35 | 60 | 120 | 75 | 150 | 30 | 65 | 7.9 | 12 | M10 | 0.23 |

| RF6205 | R/F/S/M | 152.4 | 38 | 60 | 120 | 79 | 158 | 60 | 100 | 7.9 | 15 | M12 | 0.37 |

| RF12200 | R/F/S/M | 200 | 38 | 60 | 120 | 79 | 158 | 80 | 120 | 7.9 | 15 | M12 | 0.45 |

| RF12250 | R/F/S/M | 250 | 38 | 60 | 120 | 79 | 158 | 125 | 170 | 7.9 | 15 | M12 | 0.62 |

| RF212 | R/S/M | 152.4 | 45 | 65 | 130 | 83 | 166 | 60 | 100 | 9.5(10.0) | 15 | M12 | 0.49 |

| RF17200 | R/F/S/M | 200 | 45 | 75 | 150 | 98 | 196 | 80 | 120 | 9.5(10.0) | 15 | M12 | 0.66 |

| RF17250 | R/F/S/M | 250 | 45 | 75 | 150 | 98 | 125 | 125 | 170 | 9.5(10.0) | 15 | M12 | 0.86 |

Introduction

The RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF17250 is a high-performance chain that is designed for industrial conveyor systems. It is known for its durability, strength, and resistance to wear and tear. This chain is ideal for heavy-duty applications where high loads, high speeds, and harsh environments are present.

Construction

The RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF17250 is made up of precision-pressed steel plates and pins that are heat-treated for maximum strength. It features a deep link design that provides a larger contact area and greater durability. This chain has a pitch of 1.750 inches and a width of 1.000 inches, making it suitable for a wide range of conveyor systems.

Attachments

The A1, K1, A2, and K2 attachments are designed to increase the functionality of the RF Type Conveyor Chain. The A1 attachment is a bent plate that is used to attach the chain to a conveyor system. The K1 attachment is a straight plate that is used to connect the chain to a load or another chain. The A2 and K2 attachments are similar to the A1 and K1 attachments, but with a different shape and placement.

Applications

The RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF17250 is used in a variety of industries, including automotive manufacturing, food processing, and mining. It is ideal for applications where heavy loads, high speeds, and harsh environments are present. This chain is known for its reliability, durability, and long service life.

Maintenance

To ensure the longevity and performance of the RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF17250, it is important to perform regular maintenance. This includes lubrication, inspection, and replacement of worn or damaged components. By following a regular maintenance schedule, the chain can operate at peak efficiency and minimize downtime.

Why Choose Our Stainless Steel Roller Chains?

RP Techniek BV is the authorized sales agent of Ever-power Group in the Netherlands. Our company specializes in providing high-quality stainless steel roller chains, with a focus on the RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF17250.

Our unique selling points include:

- Exceptional Product Quality: Our stainless steel roller chains are manufactured using the finest materials, ensuring durability and reliability.

- Superior Service: We are committed to providing excellent customer service, guiding our clients through the selection process and offering support whenever needed.

- Production Strength: With state-of-the-art facilities and a skilled workforce, we have the capability to meet the demands of various industries and deliver products that meet the highest standards.

In addition to the RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF17250, we also offer a wide range of other stainless steel roller chains. Whether you require standard sizes or customized solutions, we have you covered. Trust in our expertise and experience in the industry.

Sprockets for Sale

When it comes to RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF17250, it's important to have the right sprockets for optimal performance. At our company, we offer a wide range of sprockets that are suitable for this type of conveyor chain.

Our sprockets are made from high-quality materials and are available in various sizes and tooth counts to meet your specific needs. Whether you're looking for a standard sprocket or a custom-made one, we've got you covered.

In addition to RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF17250, we offer sprockets for various other types of conveyor chains. This means that whatever your conveyor system needs are, we have the right sprockets for you.

Our sprockets are not only of high quality but also competitively priced, making them an excellent choice for your business. Contact us today to learn more about our sprocket options and to place an order.

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...