Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

Specifications

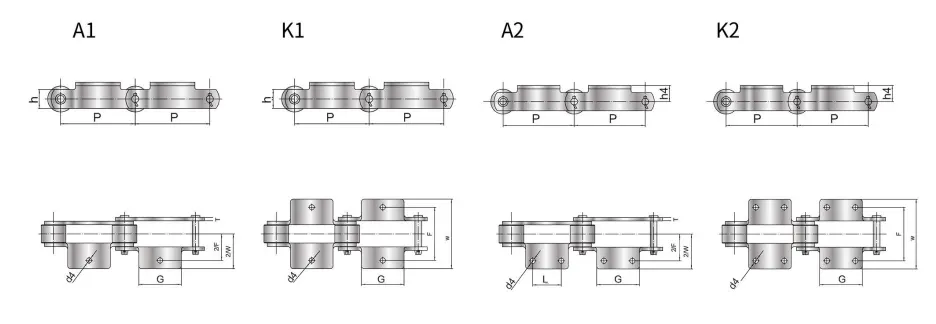

The RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF10100 has the following parameters:

| Chain No. | Roller Type | Pitch (P) |

h4 | 2/F | F | 2W | W | L | T | d4 | Bolt Dimension |

Weight of SA2 att.(KG) |

|

| RF0375 | R/F/S | 75 | 20 | 30 | 60 | 46 | 92 | 30 | 55 | 3.2 | 10 | M8 | 0.05 |

| RF03100 | R/F/S | 100 | 20 | 30 | 60 | 46 | 92 | 40 | 65 | 3.2 | 10 | M8 | 0.06 |

| RF430 | R/S | 101.6 | 22 | 40 | 80 | 54 | 108 | 40 | 70 | 4.8(5.0) | 12 | M10 | 0.11 |

| RF05075 | S | 75 | 22 | 35 | 70 | 47 | 94 | 30 | 55 | 4.5 | 10 | M8 | 0.07 |

| RF05100 | R/F/S | 100 | 22 | 35 | 70 | 47 | 94 | 40 | 65 | 4.5 | 10 | M8 | 0.08 |

| RF05150 | R/F/S | 150 | 22 | 35 | 70 | 47 | 94 | 60 | 85 | 4.5 | 10 | M8 | 0.1 |

| RF204 | S | 66.27 | 24 | 45 | 90 | 59 | 118 | - | 35 | 6.3(6.0) | 12 | M10 | 0.08 |

| RF450 | R/F/S/M | 101.6 | 28 | 50 | 100 | 64 | 128 | 40 | 70 | 6.3(6.0) | 12 | M10 | 0.18 |

| RF08150 | R/F/S/M | 150 | 28 | 50 | 100 | 64 | 128 | 60 | 90 | 6.3(6.0) | 12 | M10 | 0.22 |

| RF650 | R/F/S/M | 152.4 | 32 | 50 | 100 | 64 | 128 | 60 | 90 | 6.3(6.0) | 12 | M10 | 0.22 |

| RF10100 | R/S/M | 100 | 28 | 50 | 100 | 65 | 130 | 40 | 70 | 6.3(6.0) | 12 | M10 | 0.16 |

| RF10150 | R/F/S/M | 150 | 28 | 50 | 100 | 65 | 130 | 60 | 90 | 6.3(6.0) | 12 | M10 | 0.2 |

| RF214 | R/S/M | 101.6 | 35 | 55 | 110 | 73 | 146 | 40 | 80 | 7.9 | 15 | M12 | 0.28 |

| RF205 | S | 78.11 | 35 | 60 | 120 | 75 | 150 | 30 | 65 | 7.9 | 12 | M10 | 0.23 |

| RF6205 | R/F/S/M | 152.4 | 38 | 60 | 120 | 79 | 158 | 60 | 100 | 7.9 | 15 | M12 | 0.37 |

| RF12200 | R/F/S/M | 200 | 38 | 60 | 120 | 79 | 158 | 80 | 120 | 7.9 | 15 | M12 | 0.45 |

| RF12250 | R/F/S/M | 250 | 38 | 60 | 120 | 79 | 158 | 125 | 170 | 7.9 | 15 | M12 | 0.62 |

| RF212 | R/S/M | 152.4 | 45 | 65 | 130 | 83 | 166 | 60 | 100 | 9.5(10.0) | 15 | M12 | 0.49 |

| RF17200 | R/F/S/M | 200 | 45 | 75 | 150 | 98 | 196 | 80 | 120 | 9.5(10.0) | 15 | M12 | 0.66 |

| RF17250 | R/F/S/M | 250 | 45 | 75 | 150 | 98 | 125 | 125 | 170 | 9.5(10.0) | 15 | M12 | 0.86 |

I. Overview

The RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF10100 is a cutting-edge solution for efficient and reliable material handling in various industries. With its advanced design and high-quality materials, this conveyor chain offers exceptional performance and durability.

II. Key Features

- 1. Superior Load Capacity: The RF Type Conveyor Chain is engineered to withstand heavy loads and provide smooth and stable transportation of materials.

- 2. A1 Attachment: The A1 attachment enhances the versatility of the conveyor chain, allowing for easy connection and detachment of additional components.

- 3. K1 Attachment: The K1 attachment provides secure and reliable grip, ensuring that materials stay in place during transportation.

- 4. A2 Attachment: With the A2 attachment, the conveyor chain can be easily integrated with other equipment, expanding its functionality and adaptability.

- 5. K2 Attachment: The K2 attachment offers enhanced stability and alignment, minimizing the risk of material spillage or misplacement.

III. Applications

The RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF10100 finds wide-ranging applications in industries such as:

- 1. Manufacturing: Enables efficient movement of raw materials and finished products on assembly lines.

- 2. Food Processing: Ensures safe and hygienic transportation of food items throughout the production process.

- 3. Packaging: Facilitates the smooth flow of packaging materials, optimizing packaging operations.

- 4. Warehousing: Streamlines material handling in warehouses, improving overall operational efficiency.

- 5. Automotive: Supports the handling of automotive components and parts during production and assembly.

IV. Benefits

By choosing the RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF10100, you can experience the following benefits:

- 1. Increased Productivity: The efficient material transportation capabilities of this conveyor chain lead to improved productivity and reduced downtime.

- 2. Enhanced Safety: The secure attachment and stable grip provided by the A1 K1 A2 K2 attachments ensure safe handling of materials.

- 3. Long-lasting Performance: The high-quality materials used in the construction of this conveyor chain guarantee its longevity and durability.

- 4. Versatility: The A1 K1 A2 K2 attachments allow for easy customization and integration with other equipment, providing versatility in various applications.

- 5. Cost-effectiveness: With its reliable performance and minimal maintenance requirements, this conveyor chain offers a cost-effective solution for material handling needs.

V. Conclusion

The RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF10100 is a top-notch product that combines advanced features, durability, and versatility. From manufacturing to automotive industries, this conveyor chain proves to be a valuable asset for efficient material handling. Choose the RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF10100 to boost productivity, ensure safety, and optimize your material handling processes.

Why Choose Our Stainless Steel Roller Chains?

RP Techniek BV is the authorized sales agent of Ever-power Group in the Netherlands. Our high-quality stainless steel roller chains are designed to meet the needs of a wide range of industries, and we are proud to offer our customers the RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF10100.

Our RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF10100 is a unique product that is known for its durability, strength, and reliability. It is made from high-grade stainless steel, which makes it resistant to corrosion and wear, even in harsh environments. The A1, K1, A2, K2 attachments are designed to suit different purposes and applications, making it a versatile product.

In addition to our RF Type Conveyor Chain, we offer a wide range of other stainless steel roller chains. Our products are known for their quality, reliability, and performance. We take great pride in our production capabilities and are committed to producing the best products for our customers.

At RP Techniek BV, we strive to provide our customers with the best possible service. We work closely with our clients to understand their needs and provide them with customized solutions that meet their specific requirements. Our team of experts is always available to assist our customers with any questions or concerns that they may have.

We are committed to providing our customers with the highest quality products and services. Contact us today to learn more about our stainless steel roller chains and how we can help meet your needs.

Sprockets for Sale

When it comes to RF Type Conveyor Chain with A1 K1 A2 K2 Attachment RF10100, finding the perfect matching sprockets is essential. At our company, we offer a wide range of different types of sprockets to meet your needs. Our sprockets are designed to provide optimal performance and durability, ensuring smooth operation of your RF Type Conveyor Chain.

Whether you require a standard sprocket or a custom design, we have you covered. Our comprehensive selection includes various sizes, materials, and tooth profiles to suit different applications. With our high-quality sprockets, you can count on enhanced efficiency and longevity.

Take a look at the image below to see one of our sprockets:

For more information about our diverse range of sprockets and to discuss your specific requirements, please contact us. We are ready to assist you in finding the perfect sprocket solution for your RF Type Conveyor Chain.

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...