Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

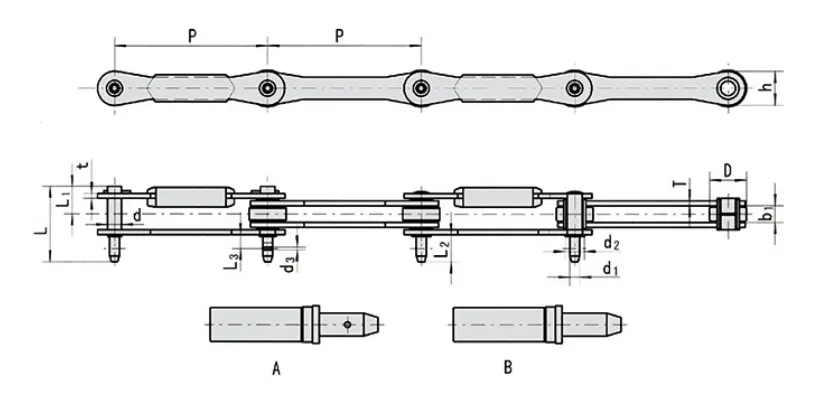

Dimensions

The P125N-DSS Stainless Steel Ice-cream Processing Chain comes with the following specifications:

| Chain No. |

Pitch | Width between inner plates |

Roller? diameter | Pin | Plate | Ultimate tensile strength | |||||||

| P | bl(min) | D(max) | d | d1 | d2 | L1 | L2 | L | Type | h | t/T | Q(min) | |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | kN | ||

| P125J-DSS | 125 | 15 | 30 | 12 | 8 | 13.3 | 20.35 | 23 | 59.6 | B | 28 | 3/4 | 32 |

| AMP125-DSS | 125 | 15 | 30 | 12 | 8 | 13.3 | 21.4 | 23 | 61.5 | A | 28 | 4 | 40 |

| P125N-DSS | 125 | 15 | 33.6 | 12 | 8 | 13.3 | 21 | 22.3 | 59.8 | B | 28 | 4 | 80 |

Introduction

The P125N-DSS Stainless Steel Ice-cream Processing Chain is a premium product designed specifically for the needs of ice-cream processing facilities. Constructed from stainless steel, this chain guarantees durability, strength, and resistance to corrosion. It features advanced attributes that allow it to endure high temperatures, significant loads, and extensive usage. This article will delve into the main characteristics and advantages of the P125N-DSS Stainless Steel Ice-cream Processing Chain.

Construction and Design

The P125N-DSS Stainless Steel Ice-cream Processing Chain consists of multiple components, such as pins, bushings, rollers, and plates. Each part is engineered to endure the challenging conditions present in ice-cream manufacturing plants. The pins and bushings utilize high-quality stainless steel to avoid rust and corrosion. The rollers undergo a special heat treatment that enhances their robustness and durability. The plates are crafted for smooth functionality, minimizing wear and extending their lifespan.

Performance and Benefits

The P125N-DSS Stainless Steel Ice-cream Processing Chain provides numerous advantages that make it an excellent choice for ice-cream manufacturing facilities. Firstly, it boasts a high load-bearing capability, meaning it can support heavy weights without risk of breaking or malfunctioning. Secondly, its operation is quiet, reducing noise levels within the plant. Thirdly, it offers an extended service life, which helps to lower downtime and maintenance expenses. Fourthly, installation and replacement are straightforward, saving both labor time and costs. Lastly, it pairs well with most ice-cream processing machinery, enhancing its versatility.

Applications and Industries

The P125N-DSS Stainless Steel Ice-cream Processing Chain finds application across various industries, including ice-cream production, confectionery, and food processing. It is compatible with various types of machinery, such as ice-cream freezers, conveyors, and mixers, and can be utilized in different stages of the production process, including mixing, freezing, and packaging. This chain is also suitable for various ice-cream varieties, such as soft-serve, gelato, and sorbet.

Maintenance and Service

The P125N-DSS Stainless Steel Ice-cream Processing Chain requires minimal upkeep. However, to maintain optimal performance and longevity, it is advisable to lubricate and clean it regularly. The chain should be inspected at intervals for signs of wear, and any damaged components should be replaced promptly. Should any technical difficulties arise, the manufacturer offers dedicated support and service to its clients.

Conclusion

The P125N-DSS Stainless Steel Ice-cream Processing Chain is a dependable and robust product that fulfills the requirements of ice-cream processing facilities. It presents numerous benefits, including excellent load-bearing capacity, quiet operation, extended lifespan, ease of installation and replacement, and compatibility with a wide range of processing equipment. Its usage spans multiple industries, including ice-cream production, confectionery, and food processing, catering to a variety of machinery and processing phases. For optimal performance and durability, regular maintenance and service are encouraged.

Why Choose Our Stainless Steel Roller Chains?

RP Techniek BV is the official sales representative for Ever-power Group in the Netherlands. We are proud to present our P125N-DSS Stainless Steel Ice-cream Processing Chain, highlighting our unique selling propositions and the exceptional quality and service we deliver. Our product is distinguished by its durability, reliability, and precision, making it the ideal option for ice-cream processing applications.

At RP Techniek BV, we are supported by robust manufacturing capabilities that guarantee consistent quality and prompt delivery of our stainless steel roller chains. We recognize the significance of reliable chain performance across various sectors, which is why we offer an extensive selection of other stainless steel roller chains as well.

Explore our wide array of stainless steel roller chains, tailored to meet diverse applications and requirements. Whether you need chains for food processing, packaging, or other industries, we have the perfect solution for you. Trust our expertise and experience to fulfill your specific needs.

Sprockets for Sale

For the optimal pairing with the P125N-DSS Stainless Steel Ice-cream Processing Chain, look no further than our extensive selection of sprockets. We provide various types of sprockets designed to cater to your specific needs and specifications.

Our sprockets are crafted with precision and durability in mind, ensuring they can endure the demands of any industrial application. Whether you require a sprocket with a particular number of teeth, pitch diameter, or bore size, we have the right options available. Our comprehensive inventory includes sprockets made from different materials, such as stainless steel, carbon steel, and plastic, allowing you to select the most appropriate choice for your needs.

With our high-quality sprockets, you can anticipate outstanding performance, long-lasting reliability, and seamless operation. We understand the importance of selecting the right sprocket for your chain, and our knowledgeable team is always available to assist you in finding the perfect match.

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...