In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

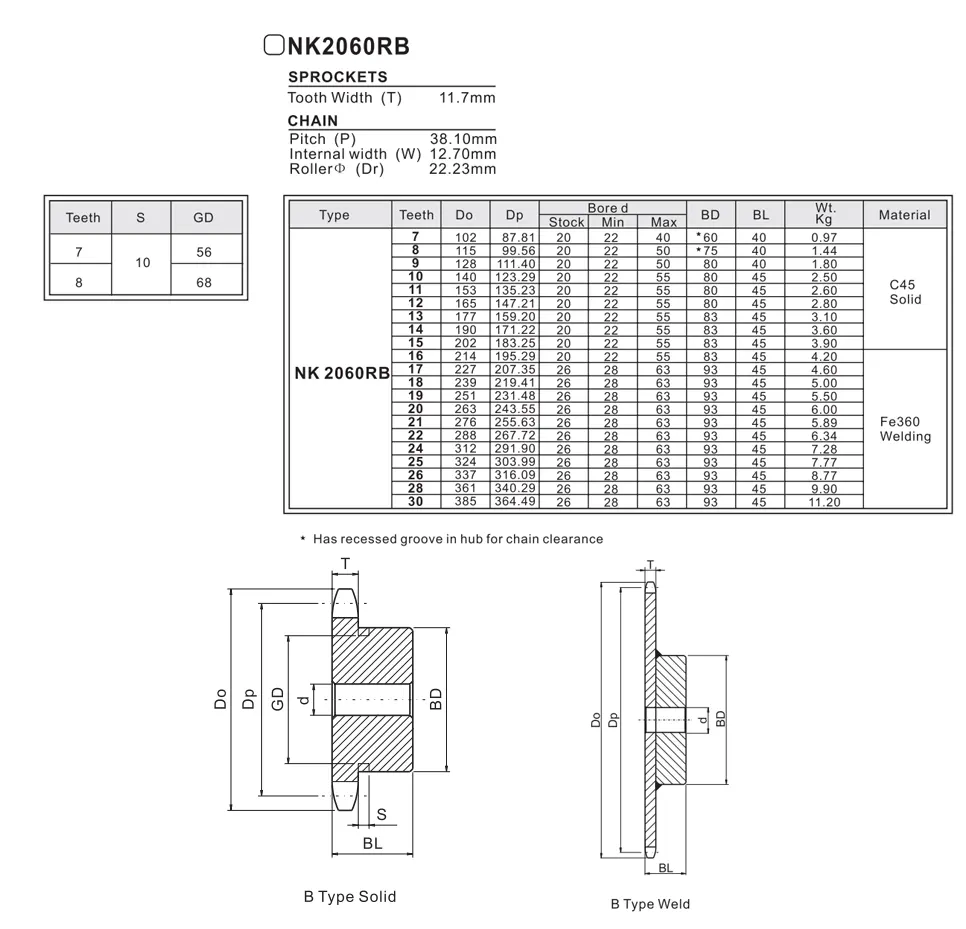

NK2060RB Double Pitch Sprocket

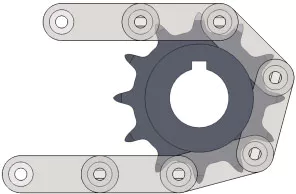

The NK2060RB Double Pitch Sprocket is designed for efficient power transmission in various machinery applications. Its robust construction ensures durability and reliability, while the double pitch design allows for versatile compatibility with chains, enhancing operational efficiency and performance.

Specifications of NK2060RB Double Pitch Sprocket

The NK2060RB Double Pitch Sprocket is a specialized component utilized in transmission systems, characterized by its innovative double pitch design. This design indicates that the distance between the teeth is larger than that found in conventional sprockets. Such a unique configuration promotes improved operational efficiency and allows for a higher load capacity, making it a preferred choice in various industrial applications.

Definition and Basic Structure

A double pitch sprocket is defined by the arrangement of its teeth, which are spaced at greater intervals compared to standard sprockets. The structure consists of a central hub from which the teeth extend outward. These teeth are meticulously shaped to mesh seamlessly with corresponding chain links, ensuring efficient power transmission between components.

Main Features of Double Pitch Sprocket

- Greater tooth spacing: The increased tooth spacing in double pitch sprockets promotes smoother engagement with the chain, which is essential for optimal performance.

- Higher load capacity: The robust structure of double pitch sprockets enables them to manage heavier loads effectively compared to standard sprockets.

- Smooth operation: With larger gaps between the teeth, double pitch sprockets contribute to a quieter operation, significantly reducing noise and vibration during functioning.

Material Selection for Double Pitch Sprocket

Double pitch sprockets can be made from various materials tailored to meet the specific requirements of different applications:

- Carbon steel: This material offers high strength and durability, making it suitable for a wide range of general applications.

- Alloy steel: Known for its enhanced hardness and wear resistance, alloy steel is ideal for use in demanding industrial settings.

- Stainless steel: With its remarkable corrosion resistance, stainless steel is perfect for applications where cleanliness and hygiene are critical.

Manufacturing Process of Double Pitch Sprocket

- Raw material preparation: Selecting the appropriate material for the sprocket manufacturing process.

- Forging or casting: Creating the initial shape of the sprocket using forging or casting methods.

- Machining: Conducting precision machining to achieve the desired dimensions and tooth profile.

- Roll forming: Forming the teeth by rolling the sprocket through specialized machinery designed for this purpose.

- Heat treatment: Applying heat treatment processes to achieve optimal hardness and toughness for the sprocket.

- Surface treatment: Enhancing corrosion resistance and aesthetics by applying surface coatings or treatments.

- Quality testing: Performing comprehensive inspections of the finished sprockets to ensure they meet established standards.

Customization Services

We offer a range of customization services for double pitch sprockets:

- Material selection: Tailoring the sprocket material to meet specific application needs and requirements.

- Tooth profile design: Customizing the tooth shape for optimal engagement and performance with the chain.

- Bore diameter and keyway: Providing options to accommodate various shaft sizes and keyway configurations.

Sprockets Supplier in the Netherlands

RP Techniek BV is the sales agent for Ever-power Group in the Netherlands and a prominent manufacturer in the power transmission products sector. We specialize in supplying high-quality sprockets, including the NK2060RB Double Pitch Sprocket, designed for optimal performance across various industrial applications. Our products are engineered to ensure durability and reliability, addressing the diverse needs of our clients.

In addition to our standard offerings, we pride ourselves on providing customized solutions tailored to meet specific customer requirements. We encourage all customers to submit drawings or samples for non-standard customizations. Our dedication lies in delivering outstanding service and products that align seamlessly with your operational needs.

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...