Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

Specifications of MC112SS MC Series Stainless Steel Hollow Pin Chain

- Chain Type: MC Series Stainless Steel Hollow Pin Chain

- Model Number: MC112SS

- Material: Stainless Steel

- Pin Type: Hollow Pin

- Pitch Size: 1.750 inches

- Working Load: 8,250 pounds

- Weight per Foot: 3.8 pounds

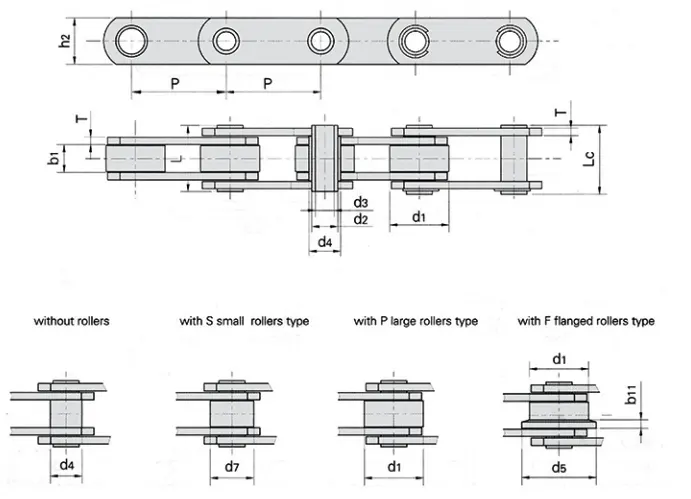

| Chain No. | Pitch | Roller diameter |

Bush diameter |

Plate depth |

width between inner plates |

pin diameter | pin length |

Plate thickness |

Breaking load |

Breaking load |

||||||||||

| P(mm) | P(mm) | P(mm) | P(mm) | P(mm) | P(mm) | d1 max (mm) |

d7 max (mm) |

d5 max (mm) |

b11 (mm) |

d4 max (mm) |

h2 max (mm) |

b1 min (mm) |

d2 min (mm) |

d3 min (mm) |

L max (mm) |

Lc max (mm) |

T max (mm) |

Q min (KN/LB) |

*Q min (KN/LB) |

|

| MC28SS | 63 | 80 | 100 | 125 | 160 | 36 | 25 | 45 | 4.5 | 17.5 | 25 | 20 | 13 | 8.2 | 36 | 38.5 | 3.5 | 19.6/4454.8 | 28/6363.7 | |

| MC56SS | 80 | 100 | 125 | 160 | 200 | 250 | 50 | 30 | 60 | 5 | 21 | 35 | 24 | 15.5 | 10.2 | 45 | 47.5 | 4 | 39.2/8908.9 | 63/14317.8 |

| MC112SS | 100 | 125 | 160 | 200 | 250 | 315 | 70 | 42 | 85 | 7 | 29 | 50 | 32 | 22 | 14.3 | 62.5 | 64.3 | 6 | 78.4/17817.8 | 126/28635.6 |

| MC224SS | 160 | 200 | 250 | 315 | 400 | 500 | 100 | 60 | 120 | 10 | 41 | 70 | 43 | 31 | 20.3 | 83 | 85.5 | 8 | 156.8/35636.3 | 245/55680.8 |

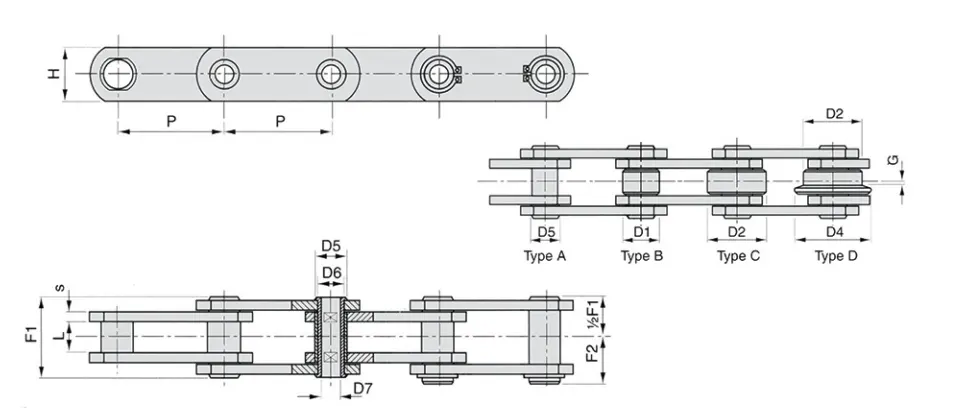

| Chain No. |

P | L | D1 | D2 | D4 | G | D5 | D6 | D7 | H | S | F1 | F2 | Breaking (load kN) |

Mass Type C (kg/m) |

| MC28SS | 50 | 20 | 25 | 36 | 45 | 4.5 | 17 | 13 | 8.2 | 25 | 3 | 36 | 20.5 | 19.6 | 4.3 |

| MC28SS | 63 | 20 | 25 | 36 | 45 | 4.5 | 17 | 13 | 8.2 | 25 | 3 | 36 | 20.5 | 19.6 | 3.8 |

| MC28SS | 80 | 20 | 25 | 36 | 45 | 4.5 | 17 | 13 | 8.2 | 25 | 3 | 36 | 20.5 | 19.6 | 3.2 |

| MC28SS | 100 | 20 | 25 | 36 | 45 | 4.5 | 17 | 13 | 8.2 | 25 | 3 | 36 | 20.5 | 19.6 | 2.8 |

| MC28SS | 125 | 20 | 25 | 36 | 45 | 4.5 | 17 | 13 | 8.2 | 25 | 3 | 36 | 20.5 | 19.6 | 2.5 |

| MC56SS | 63 | 24 | 30 | 50 | 60 | 7 | 21 | 15.5 | 10.2 | 35 | 4 | 45 | 25 | 39.2 | 8.5 |

| MC56SS | 80 | 24 | 30 | 50 | 60 | 7 | 21 | 15.5 | 10.2 | 35 | 4 | 45 | 25 | 39.2 | 7.2 |

| MC56SS | 100 | 24 | 30 | 50 | 60 | 7 | 21 | 15.5 | 10.2 | 35 | 4 | 45 | 25 | 39.2 | 6.2 |

| MC56SS | 125 | 24 | 30 | 50 | 60 | 7 | 21 | 15.5 | 10.2 | 35 | 4 | 45 | 25 | 39.2 | 5.4 |

| MC56SS | 160 | 24 | 30 | 50 | 60 | 7 | 21 | 15.5 | 10.2 | 35 | 4 | 45 | 25 | 39.2 | 4.7 |

| MC112SS | 80 | 32 | 42 | 70 | 85 | 8.5 | 29 | 22 | 14.3 | 50 | 6 | 62.5 | 33 | 78.4 | 16.6 |

| MC112SS | 100 | 32 | 42 | 70 | 85 | 8.5 | 29 | 22 | 14.3 | 50 | 6 | 62.5 | 33 | 78.4 | 14 |

| MC112SS | 125 | 32 | 42 | 70 | 85 | 8.5 | 29 | 22 | 14.3 | 50 | 6 | 62.5 | 33 | 78.4 | 11.2 |

| MC112SS | 160 | 32 | 42 | 70 | 85 | 8.5 | 29 | 22 | 14.3 | 50 | 6 | 62.5 | 33 | 78.4 | 10.2 |

| MC112SS | 200 | 32 | 42 | 70 | 85 | 8.5 | 29 | 22 | 14.3 | 50 | 6 | 62.5 | 33 | 78.4 | 8.9 |

| MC112SS | 250 | 32 | 42 | 70 | 85 | 8.5 | 29 | 22 | 14.3 | 50 | 6 | 62.5 | 33 | 156.8 | 7.9 |

| MC224SS | 125 | 43 | 60 | 100 | 120 | 10.5 | 42 | 30 | 20.3 | 70 | 8 | 83 | 44 | 156.8 | 32.3 |

| MC224SS | 160 | 43 | 60 | 100 | 120 | 10.5 | 42 | 30 | 20.3 | 70 | 8 | 83 | 44 | 156.8 | 27.1 |

| MC224SS | 200 | 43 | 60 | 100 | 120 | 10.5 | 42 | 30 | 20.3 | 70 | 8 | 83 | 44 | 156.8 | 23.5 |

| MC224SS | 250 | 43 | 60 | 100 | 120 | 10.5 | 42 | 30 | 20.3 | 70 | 8 | 83 | 44 | 156.8 | 20.6 |

| MC224SS | 315 | 43 | 60 | 100 | 120 | 10.5 | 42 | 30 | 20.3 | 70 | 8 | 83 | 44 | 156.8 | 17.2 |

MC112SS MC Series Stainless Steel Hollow Pin Chain

Introduction

The MC112SS MC Series Stainless Steel Hollow Pin Chain is a versatile and durable chain that is designed to meet the demands of various industrial applications. This high-quality chain is specifically engineered to provide reliable performance in challenging environments.

Key Features

1. Corrosion Resistance

2. High Strength

3. Smooth Operation

4. Easy Installation

5. Extended Service Life

Corrosion Resistance

The MC112SS MC Series Stainless Steel Hollow Pin Chain is constructed using premium quality stainless steel material, which offers excellent resistance against corrosion and rust. This ensures the chain's longevity, even when exposed to harsh conditions such as moisture, chemicals, and extreme temperatures.

High Strength

With its robust construction and advanced engineering, this chain provides exceptional strength and load-bearing capacity. It is capable of handling heavy loads and can withstand the rigors of demanding industrial applications. The high strength of the chain makes it a reliable choice for various material handling and conveying systems.

Smooth Operation

The MC112SS MC Series Stainless Steel Hollow Pin Chain features precision-machined components that ensure smooth and efficient operation. The chain's low friction design minimizes wear and tear, reducing the need for frequent maintenance and enhancing overall productivity. Its reliable performance guarantees uninterrupted operation in critical production processes.

Easy Installation

Installing the MC112SS MC Series Stainless Steel Hollow Pin Chain is hassle-free and time-efficient. The chain is designed with easy-to-use attachment options, allowing for quick and secure installation. This saves valuable time during setup and ensures a smooth transition from old to new chains in existing systems.

Extended Service Life

Designed for longevity, the MC112SS MC Series Stainless Steel Hollow Pin Chain offers an extended service life. Its durable construction and resistance to wear and fatigue ensure reliable performance over a prolonged period. This reduces the frequency of chain replacements, resulting in cost savings and increased productivity.

The MC112SS MC Series Stainless Steel Hollow Pin Chain is the ideal choice for industries such as food processing, packaging, pharmaceuticals, and chemical manufacturing. Its exceptional corrosion resistance, high strength, smooth operation, easy installation, and extended service life make it a reliable and cost-effective solution for various applications.

Why Choose Our Stainless Steel Roller Chains?

RP Techniek BV is the Dutch sales agent of Ever-power Group, and we are proud to introduce our MC112SS MC Series Stainless Steel Hollow Pin Chain. Our stainless steel roller chains come with unique selling points that emphasize our product quality, exceptional service, and demonstrate our manufacturing capabilities.

At RP Techniek BV, we prioritize the highest standards of quality control to ensure our stainless steel roller chains meet or exceed industry requirements. Our chains are made from premium-grade stainless steel, providing excellent resistance to corrosion, extreme temperatures, and harsh environmental conditions. This durability ensures a longer service life for our customers, ultimately reducing maintenance costs.

Furthermore, our dedicated customer service team is readily available to provide technical support and assist with any inquiries or challenges you may encounter. We prioritize customer satisfaction and strive to exceed expectations by offering personalized solutions and prompt responses.

In addition to the MC112SS MC Series Stainless Steel Hollow Pin Chain, we offer a wide range of other stainless steel roller chains to cater to various applications. Our extensive selection ensures that we can meet the diverse needs of our customers, providing reliable solutions for different industries.

To demonstrate our commitment to excellence, we have included an image below showcasing our manufacturing capabilities.

Sprockets for Sale

If you are in need of a reliable and durable chain system, look no further than our collection of high-quality Sprockets. Our MC112SS MC Series Stainless Steel Hollow Pin Chain is the perfect match for our selection of sprockets.

We offer a wide variety of sprockets to suit your specific needs. Our products are designed to provide optimal performance and durability. Our sprockets are made from premium materials and are built to last. We ensure that our sprockets meet the highest standards of quality, so you can rely on them to perform under even the most demanding conditions.

Whether you need standard sprockets or customized sprockets, we have the right product for you. Our sprockets are available in different sizes and configurations to ensure that you get the perfect fit for your chain system. We also offer a range of finishes to suit your preferences.

So, if you are looking for sprockets that will stand the test of time, look no further than our collection. With our commitment to quality, you can trust our sprockets to deliver reliable performance for years to come.

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...